Method for preparing titanium dioxide nano-rod array materials at low temperature

A nanorod array and titanium dioxide technology, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, metal material coating technology, etc., can solve the problems of surfactant addition and use in complex processes, and achieve easy monitoring and control and environmental pollution The effect of less and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

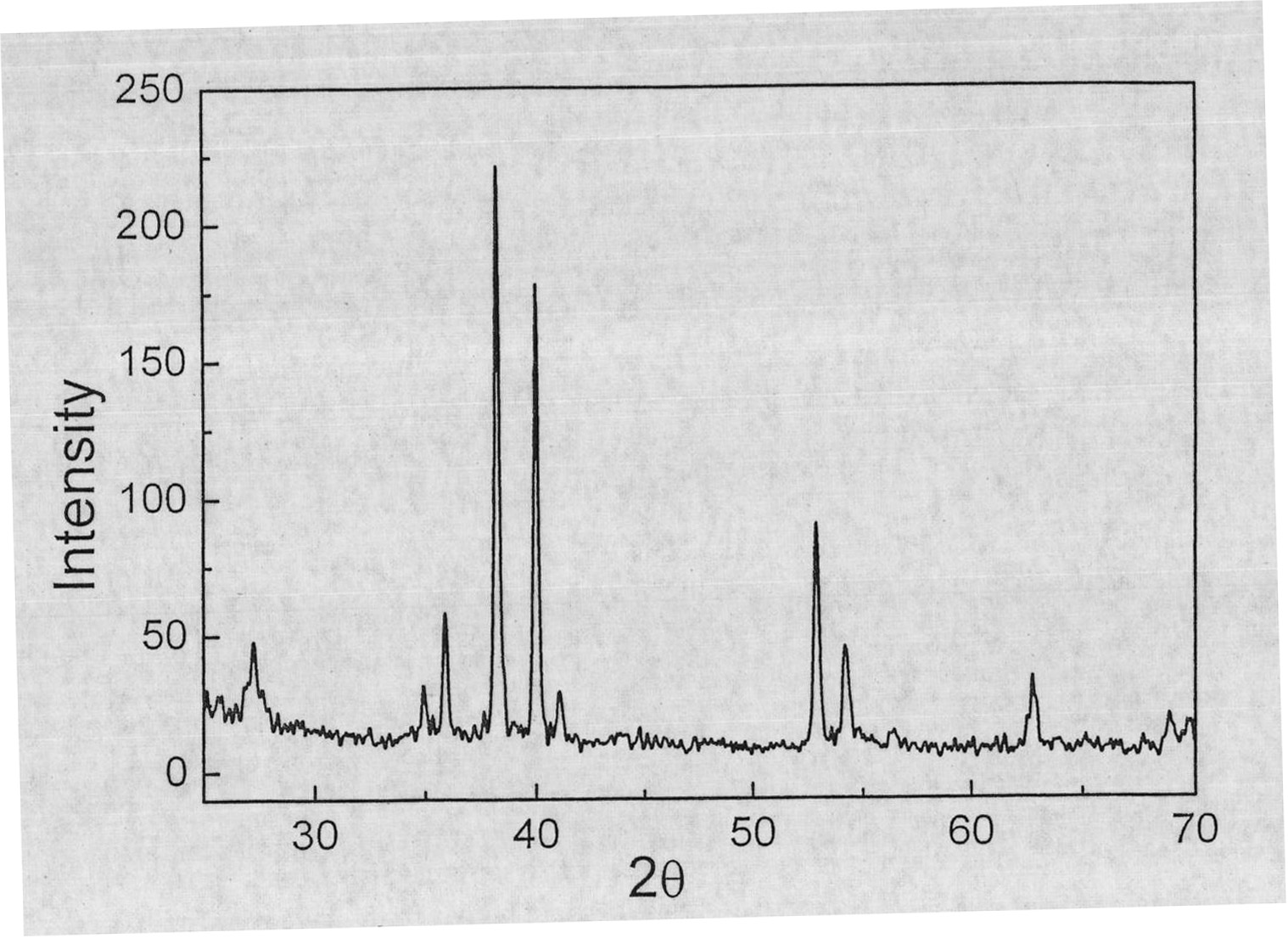

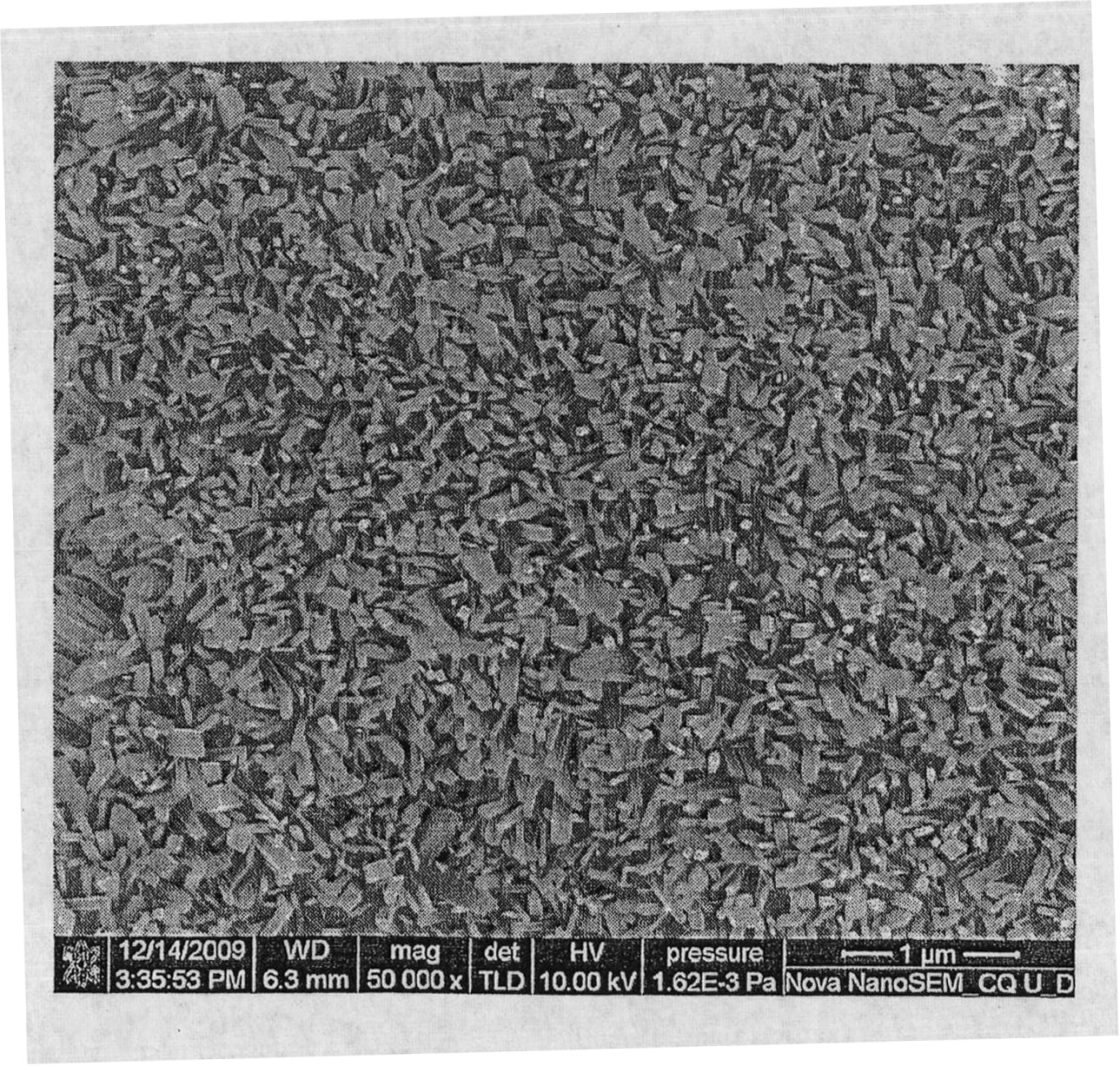

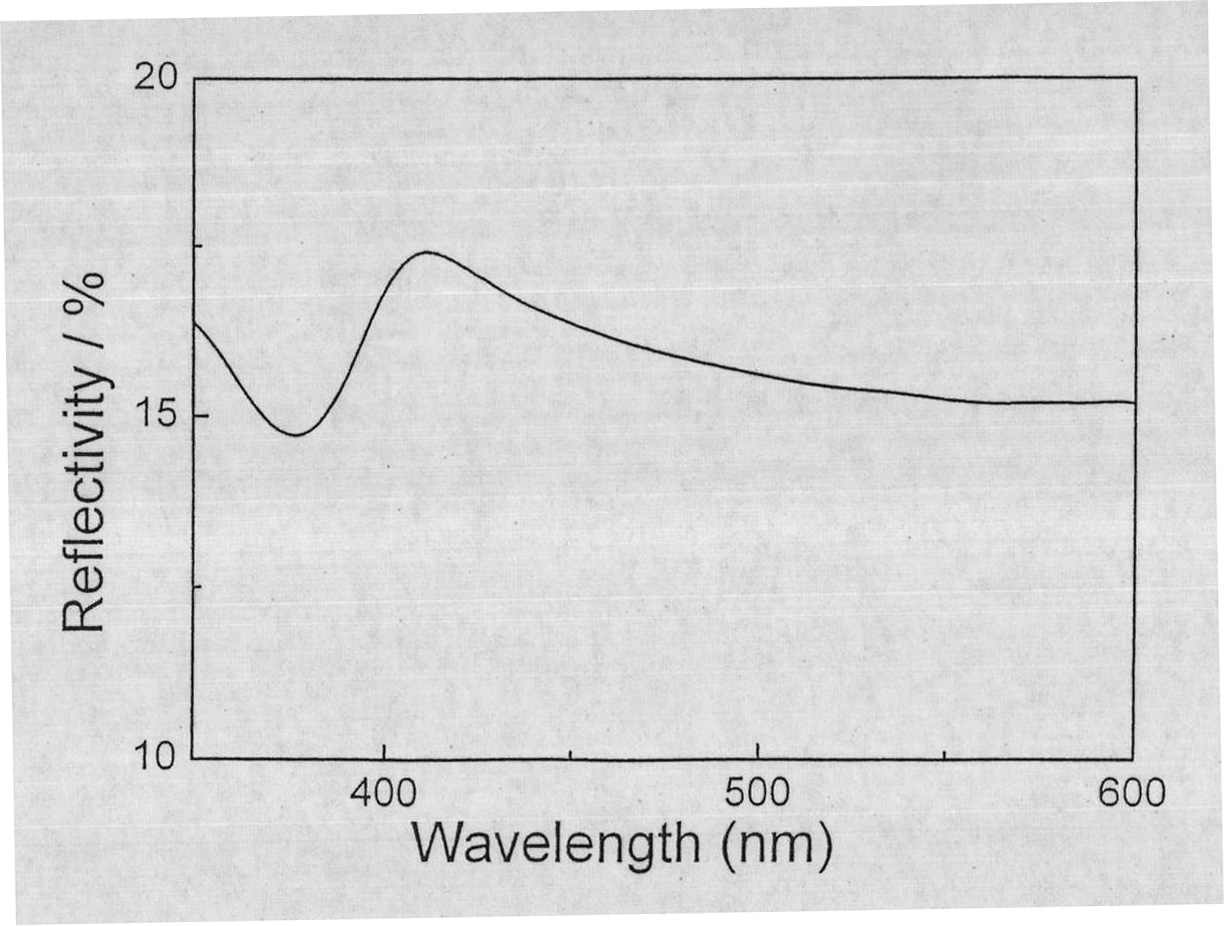

[0031] Specific synthesis method of low-temperature titania nanorod arrays

[0032] The raw material for synthesizing titanium dioxide nanorod array material is hydrochloric acid (HCl), the reaction that titanium substrate (Ti) takes place is as follows:

[0033] Ti+4HCl→TiCl 4 +2H 2 ,

[0034] TiCl 4 +3H 2 O→H 2 TiO 3 ↓+4HCl,

[0035]

[0036] The specific operation steps are as follows:

[0037] Step 1, cleaning of the titanium substrate, the titanium substrate is ultrasonicated for 10 minutes in a mixed solution of alcohol and acetone with a volume ratio of 1:1, and rinsed with deionized water;

[0038] Step 2, remove the oxide layer of the titanium substrate, put the titanium substrate in 7% hydrochloric acid solution, heat it at 95°C in a water bath heater for 10 minutes, rinse it with deionized water, and finally dry it for use;

[0039] Step 3, preparing a reaction solvent, dissolving hydrochloric acid in an appropriate amount of water, and controlling the c...

Embodiment 2

[0042] Specific synthesis method of low-temperature titania nanorod arrays

[0043] The raw material for synthesizing titanium dioxide nanorod array material is hydrochloric acid (HCl), the reaction that titanium substrate (Ti) takes place is as follows:

[0044] Ti+4HCl→TiCl 4 +2H 2 ,

[0045] TiCl 4 +3H 2 O→H 2 TiO 3 ↓+4HCl,

[0046]

[0047] The specific operation steps are as follows:

[0048] Step 1, cleaning of the titanium substrate, the titanium substrate is ultrasonicated for 10 minutes in a mixed solution of alcohol and acetone with a volume ratio of 1:1, and rinsed with deionized water;

[0049] Step 2, remove the oxide layer of the titanium substrate, put the titanium substrate into 18% hydrochloric acid solution, heat it at 65°C in a water bath heater for 10 minutes, rinse it with deionized water, and finally dry it for use;

[0050] Step 3, preparing a reaction solvent, dissolving hydrochloric acid in an appropriate amount of water, and controlling th...

Embodiment 3

[0053] Specific synthesis method of low-temperature titania nanorod arrays

[0054] The raw material for synthesizing titanium dioxide nanorod array material is hydrochloric acid (HCl), the reaction that titanium substrate (Ti) takes place is as follows:

[0055] Ti+4HCl→TiCl 4 +2H 2 ,

[0056] TiCl 4 +3H 2 O→H 2 TiO 3 ↓+4HCl,

[0057]

[0058] The specific operation steps are as follows:

[0059] Step 1, cleaning of the titanium substrate, the titanium substrate is ultrasonicated for 10 minutes in a mixed solution of alcohol and acetone with a volume ratio of 1:1, and rinsed with deionized water;

[0060] Step 2, remove the oxide layer of the titanium substrate, put the titanium substrate into 10% hydrochloric acid solution, heat it at 80°C in a water bath heater for 10 minutes, rinse it with deionized water, and finally dry it for use;

[0061] Step 3, preparing a reaction solvent, dissolving hydrochloric acid in an appropriate amount of water, and controlling the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com