Portable centrifugal internal combustion tamping pick

A portable, tamping pick technology, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of incomplete application, weakening of ballast strength, and affecting the elasticity of the ballast bed, etc., to achieve small size, prolong service life, and tamping operations easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the internal combustion centrifugal type tamping pick is described in detail below in conjunction with the accompanying drawings:

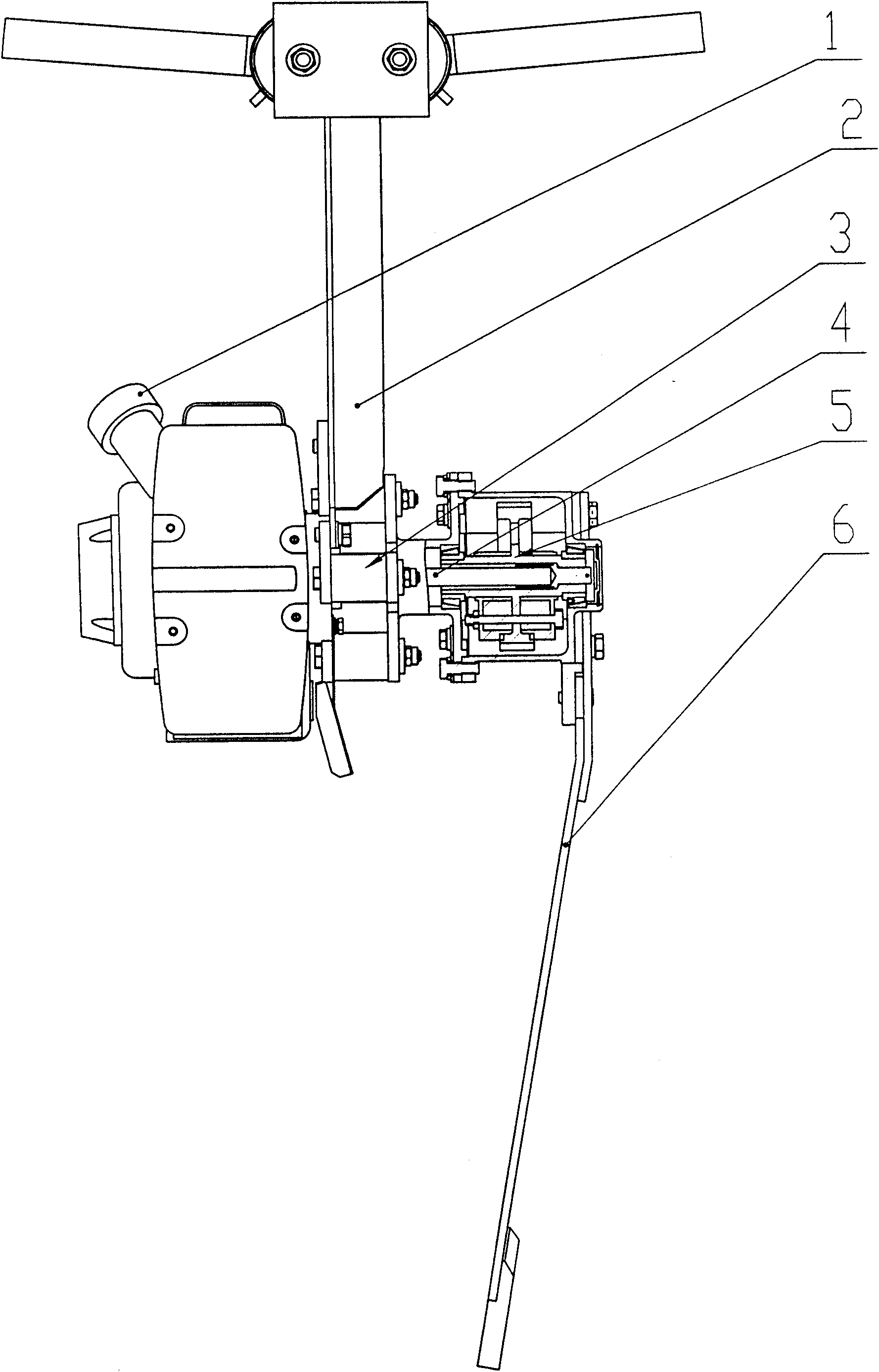

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown: this tamping pick has a frame assembly 2 and an internal combustion engine 1 and a centrifugal vibrating device 5 installed on the frame assembly 2 , and a tamping plate 6 installed on the centrifugal vibrating device 5 . The power of the internal combustion engine 1 is connected to the centrifugal vibrating device 5 through the flexible shaft 4 . The upper end of the tamping plate 6 is fixed with the shell 8 of the centrifugal vibrating device 5, which has a bending angle downward.

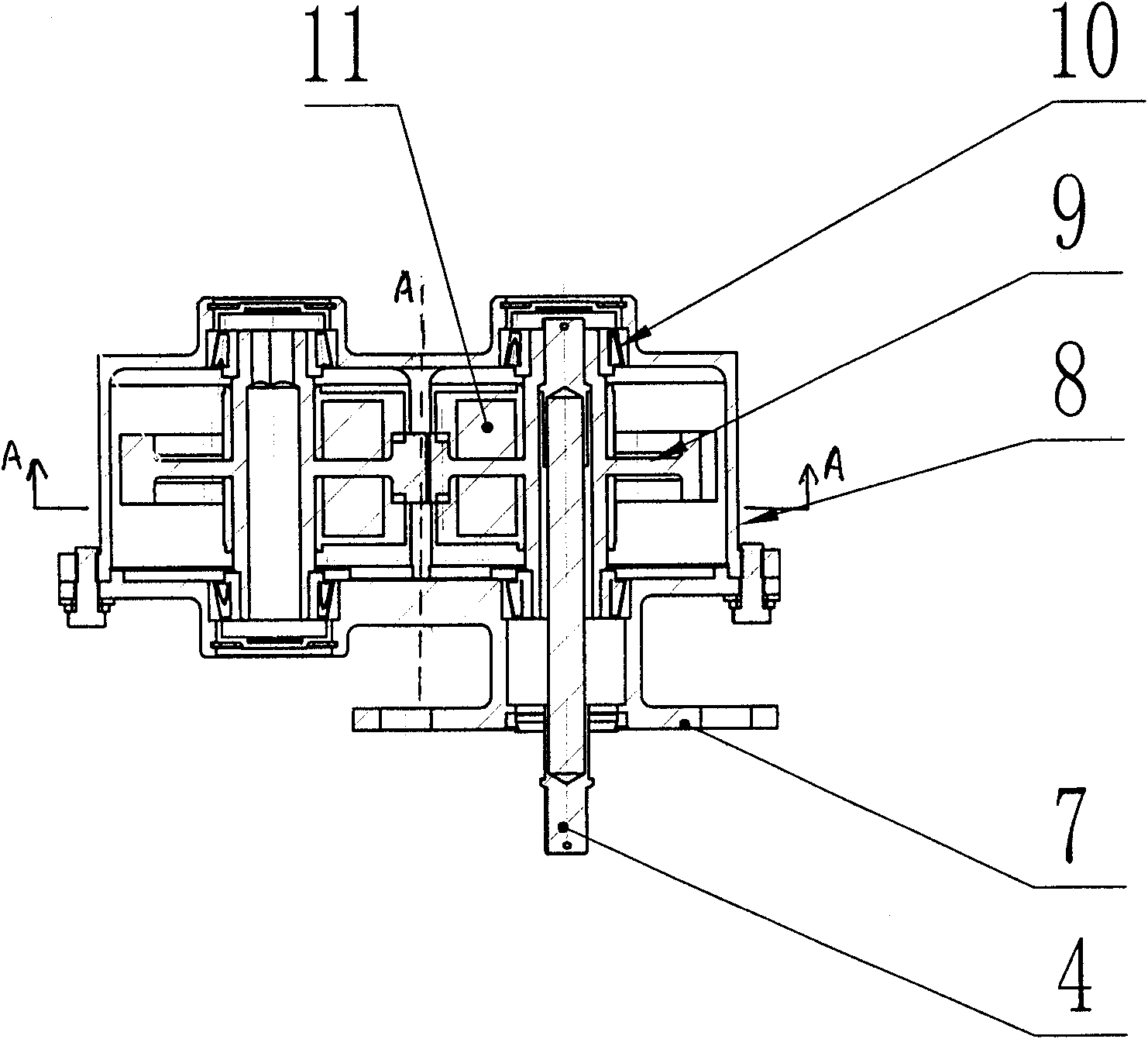

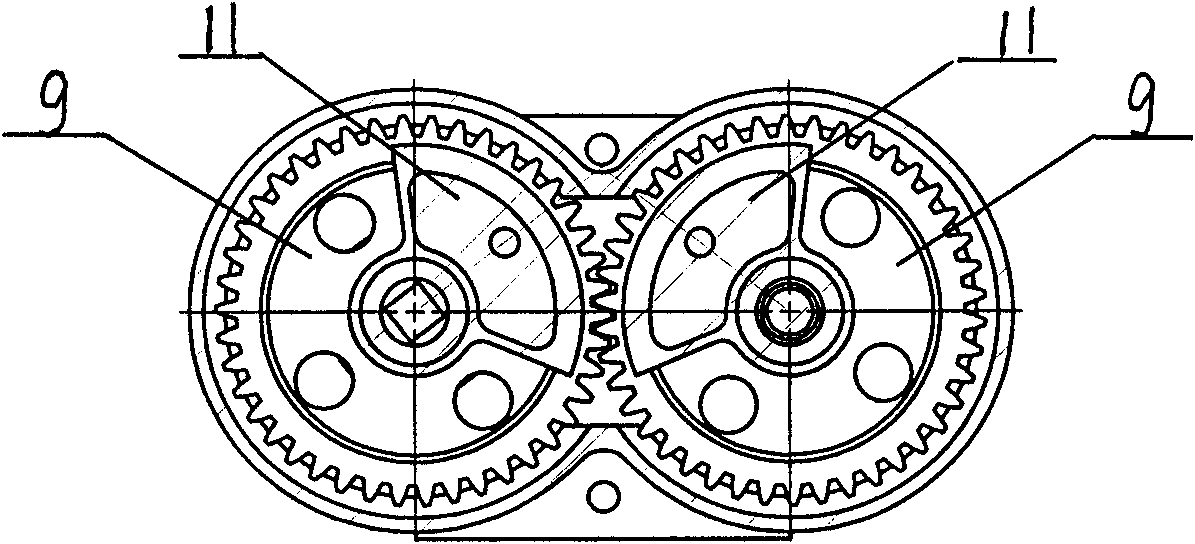

[0029] see figure 2 , wherein the centrifugal vibration device 5 is composed of a driving gear 9 , a driven gear 12 , an eccentric block 11 , a housing 8 and an end cover 7 . The driving gear 9 is connected with the power output flexible shaft 4 of the internal combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com