Intelligent sliding bearing capable of adjusting viscosity of lubricating fluid automatically and control method thereof

An automatic adjustment and sliding bearing technology, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., to improve tribological properties, improve lubrication effects, and prevent leakage from polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

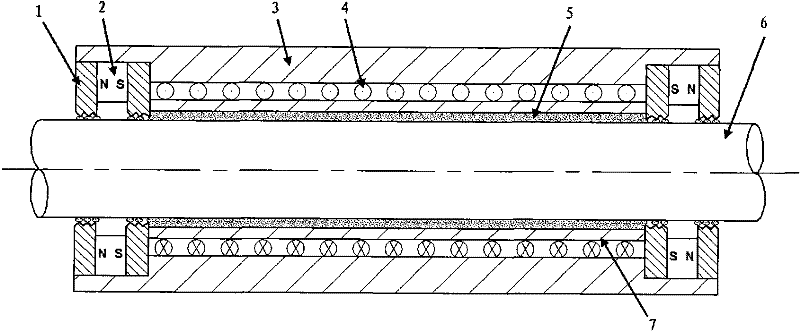

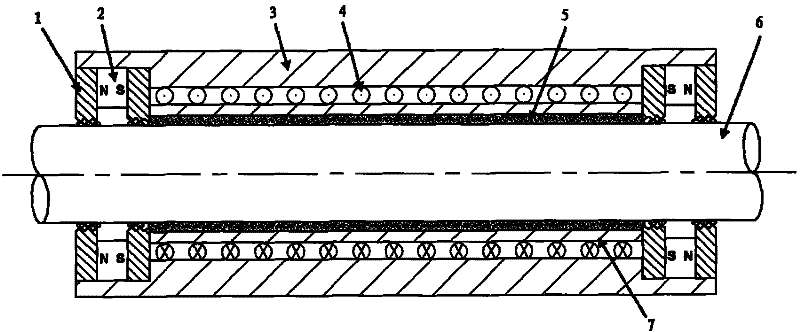

[0015] The structure of the smart sliding bearing is as follows figure 1 As shown, the coils arranged in the inner sleeve of the bearing can change the magnetic field inside the bearing, thereby adjusting the viscosity of the lubricant and improving the tribological properties. In the design, the bearing inner sleeve is made of metal with certain mechanical strength and magnetic conductivity, such as cast iron and carbon steel; the coil is wound with common enameled wire; Strong rare-earth permanent magnets; the pole pieces are machined from ferromagnetic electric pure iron.

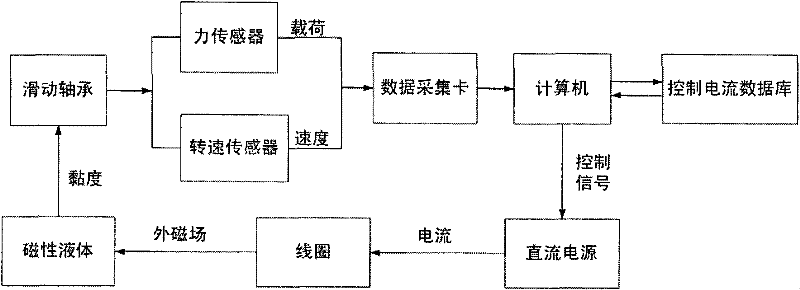

[0016] When the bearing is running, first measure the speed and load of the rotating shaft through an external sensor, and then collect the signal of the sensor to the computer through the data acquisition card, then compare the measured speed and load information with the database in the computer, and output the signal Controls the voltage of the DC power supply. The DC power supply is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com