Flexible matrix inorganic electroluminescent flat-panel display

A flat-panel display and luminescence technology, which is applied in the direction of electric solid-state devices, instruments, circuits, etc., can solve the problems that the terminal display cannot be used, and the text, pattern, color, and grayscale dynamic changes cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

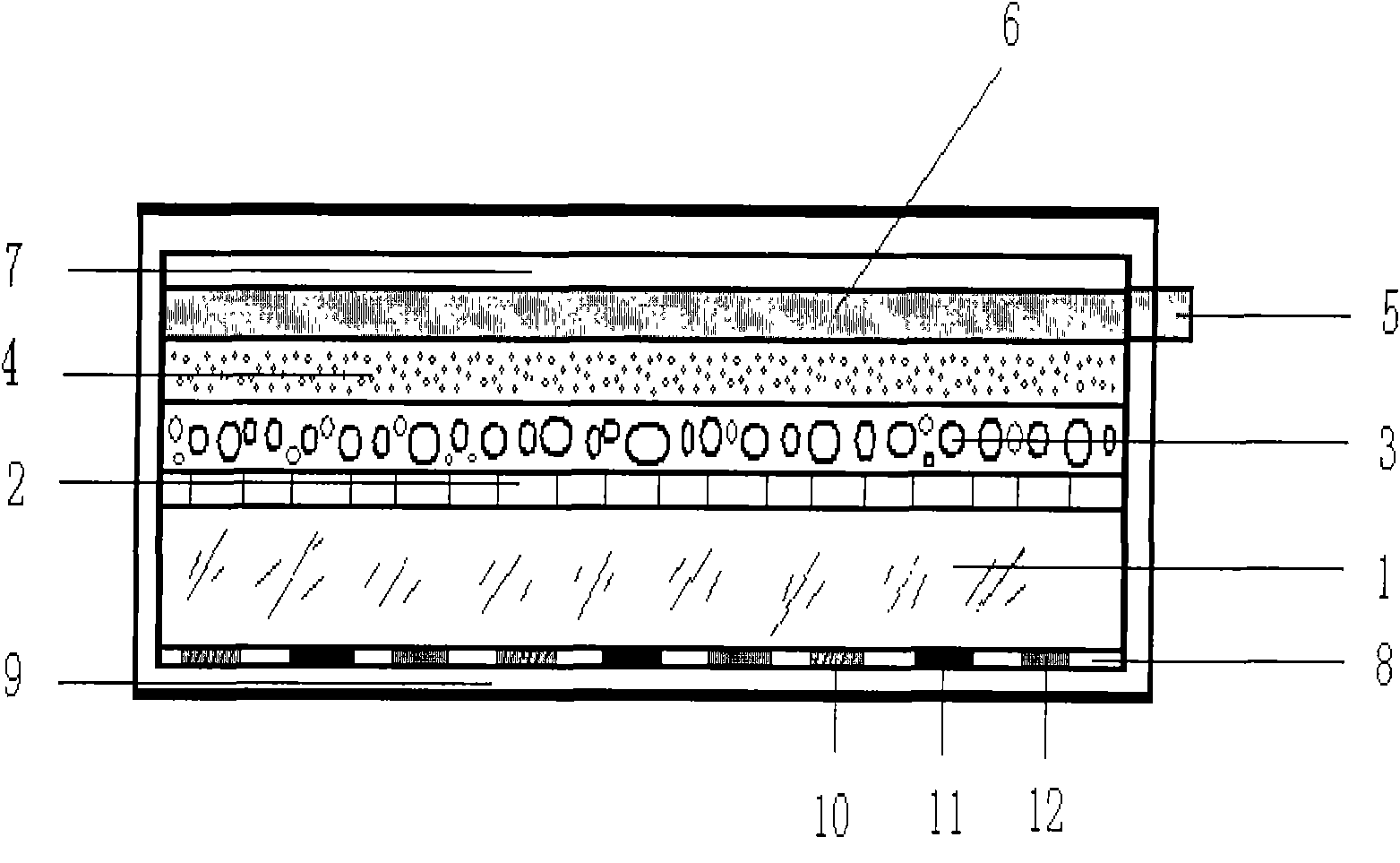

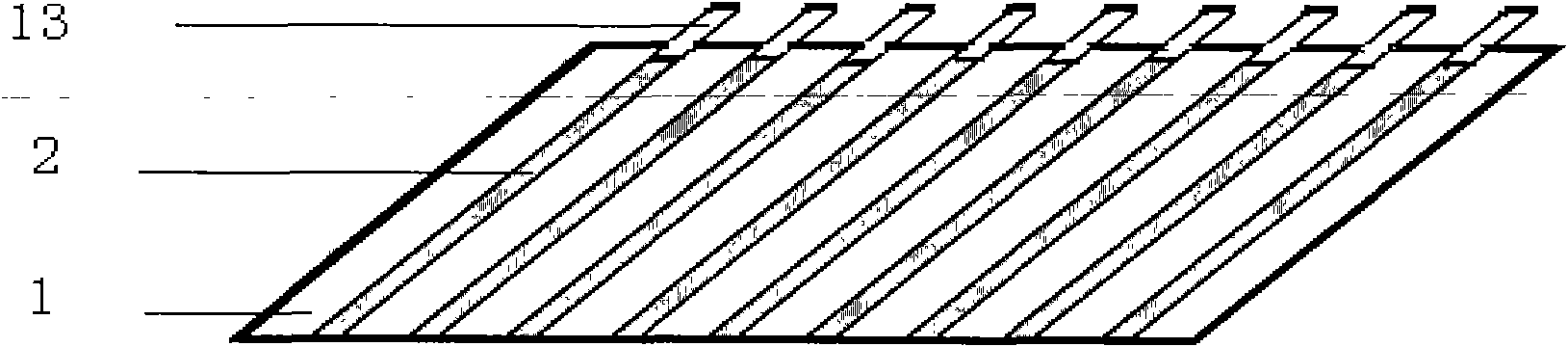

[0035] Choose PET plastic film, use ITO conductive liquid to print the transparent conductive layer, the transparent electrode width is 2mm, the dividing line width is 0.5mm, and it is dried at a temperature of 100 degrees. The electrode leads are connected with wires using silver glue.

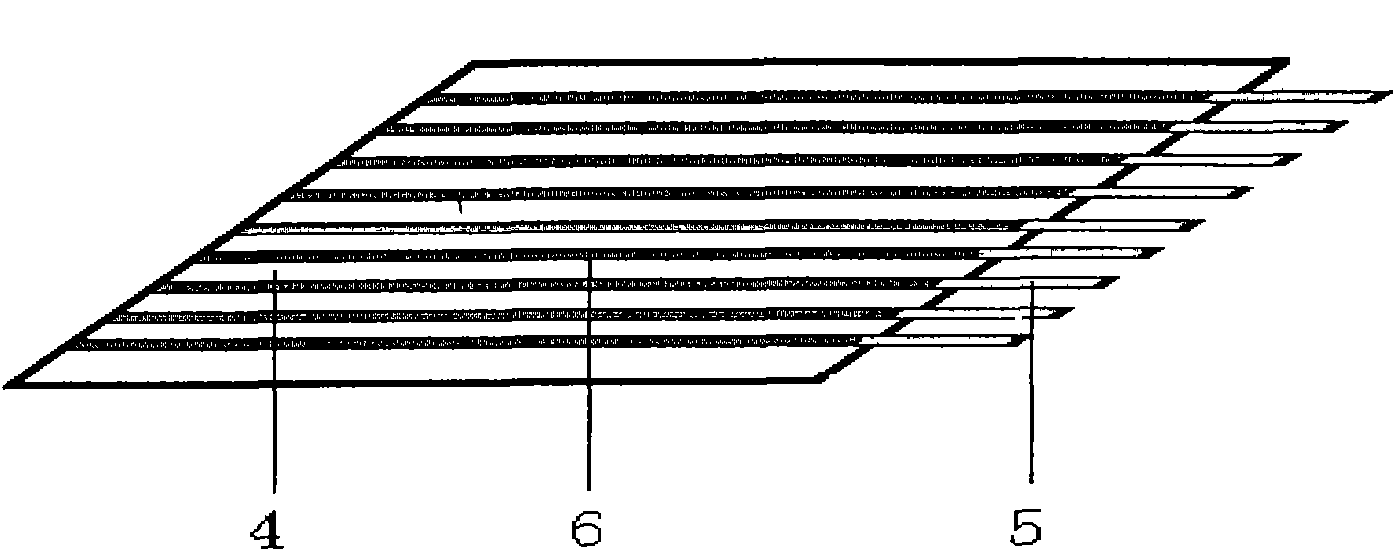

[0036] Use D502 luminescent material mixed with fluorine paint glue, print with screen printing process, and dry at 100 degrees.

[0037] Mix barium titanate with fluorine paint glue, print by screen printing, and dry at 100 degrees.

[0038] Use silver paste to screen-print the back electrode vertically, the width of the back electrode is 2mm, the width of the dividing line is 0.5mm, and the electrode is connected to the wire with silver glue. And dry at a temperature of 100 degrees.

[0039] Print the overlay protective layer with insulating ink.

[0040] Red, blue, and green fluorescent color coatings can be printed or printed on the outside of the transparent flexible plastic base laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com