Crushing method and device thereof for peeling metal and nonmetal in waste cables

A waste cable and non-metal technology, applied in the field of crushing and device stripping metal and non-metal in waste cables, can solve the problems of crushing equipment tool damage, noise pollution, roughness, etc., to reduce the loss of metal resources, enhance Adaptive, likelihood-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

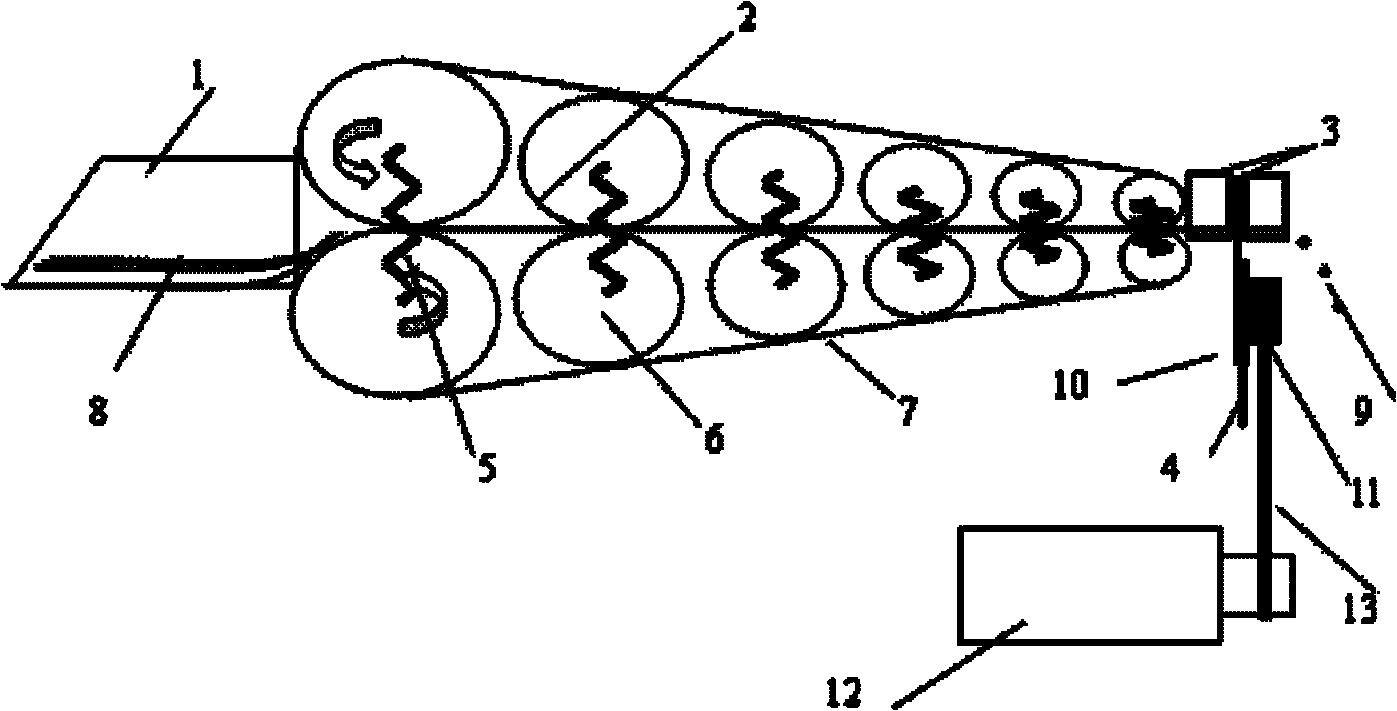

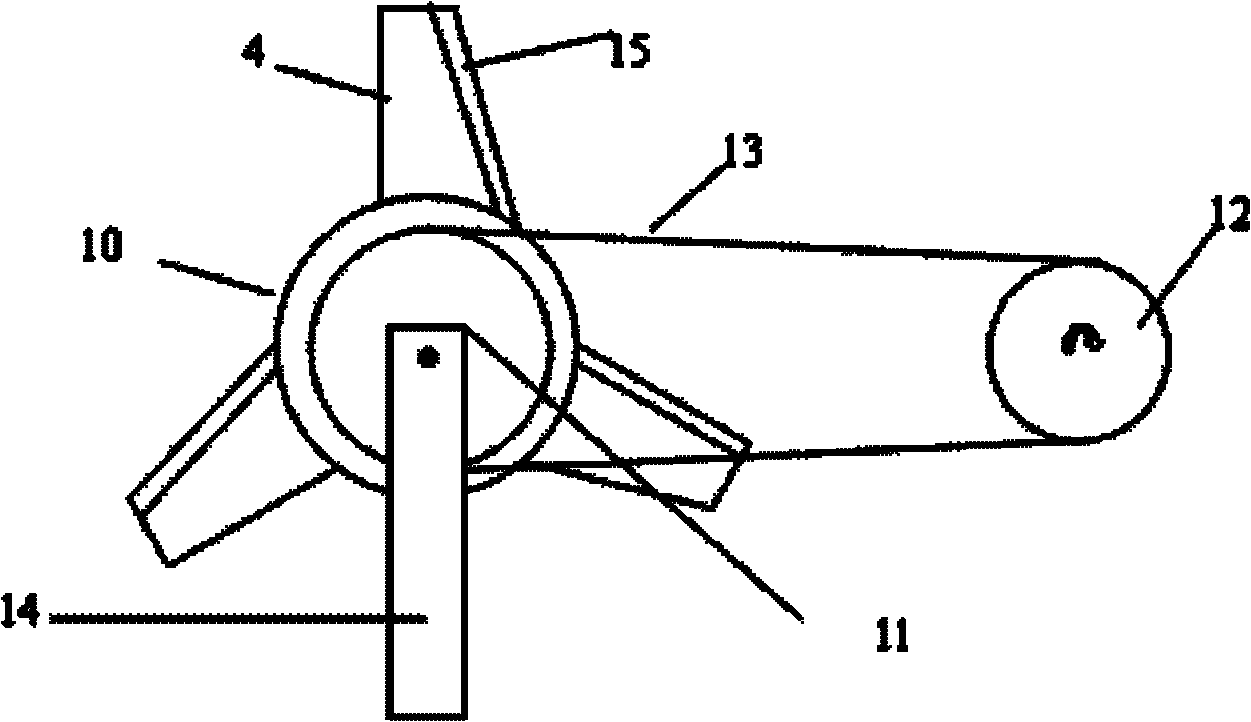

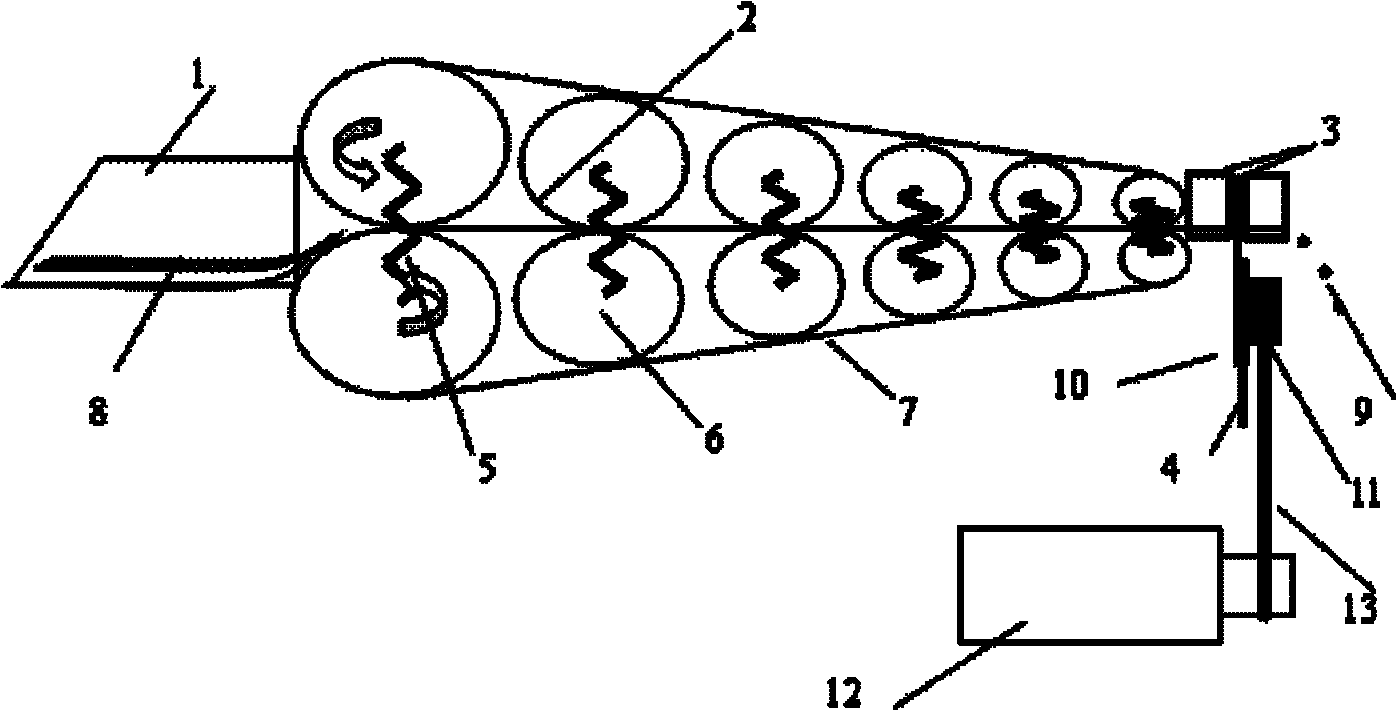

[0024] The schematic diagram of the technological process and device for shearing and shredding of waste cables to strip metal and non-metal in waste cables is as follows: figure 1 and figure 2 shown. Waste and old cables 8 enter the material conveying device 2 through the material inlet 1, and enter into two separate groove-type shearing tables 3 under the action of the compression spring 5, the pulley 6 and the belt 7, and the waste and old cables enter into the material conveying device 2 under the action of the compression spring 5, pulley 6 and belt 7. The rotation of the blade 15 cuts the cable into particles 9 of a certain length through the space between the two slot-type shearing stations. The motor 12 drives the pulley 11 through the belt 13, and then drives the cutter to fix the rotating wheel 10 to rotate the shear cutter 4, thereby completing the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com