V-shaped micro-strip meander-line slow wave structure

A technology of slow wave structure and zigzagging lines, applied in the field of traveling wave tube amplifiers, can solve the problems of narrow operating frequency band of traveling wave tubes, limited application development, and small coupling impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

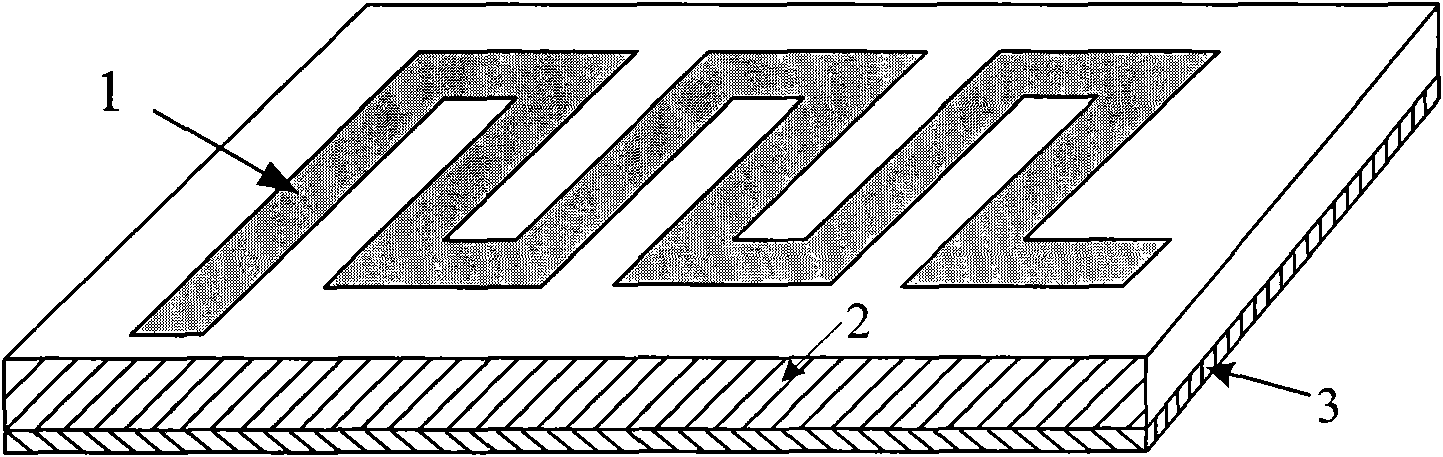

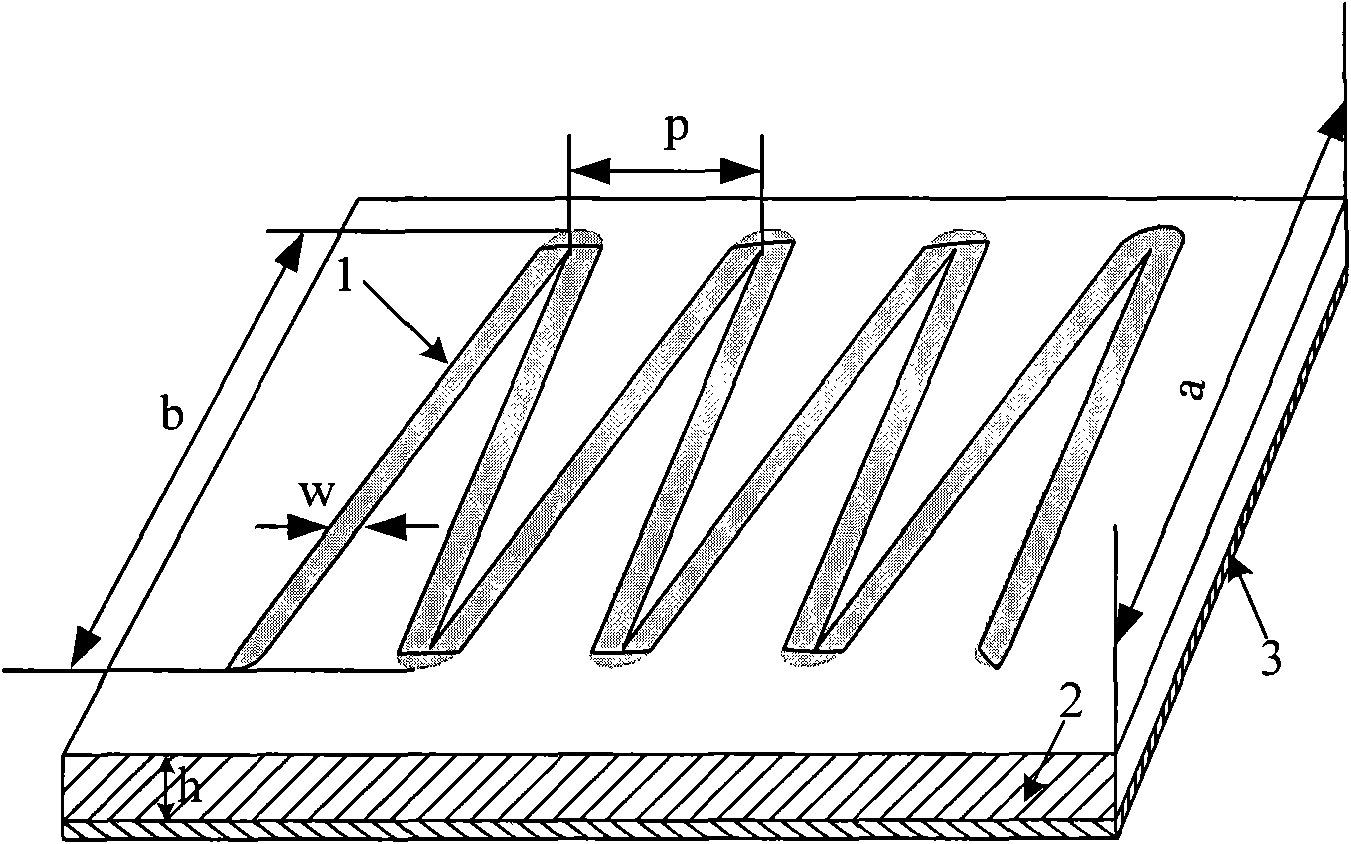

[0027] A V-shaped microstrip meander slow-wave structure, such as image 3 As shown, it includes a microstrip transmission line structure formed by a metal base plate 3 , a dielectric layer 2 and a planar metal line 1 . The dielectric layer 2 is located between the metal bottom plate 3 and the plane metal wire 1 , and its shape is the same as that of the metal bottom plate 3 . The planar metal wire 1 is composed of a plurality of planar metal wire segments of the same shape and size connected end to end to form a zigzag structure; wherein two adjacent planar metal wire segments form a "V" shape or an inverted "V" shape, and a "V" shape or an inverted "V" "The included angle (2θ) of the font is less than 180 degrees.

Embodiment approach 2

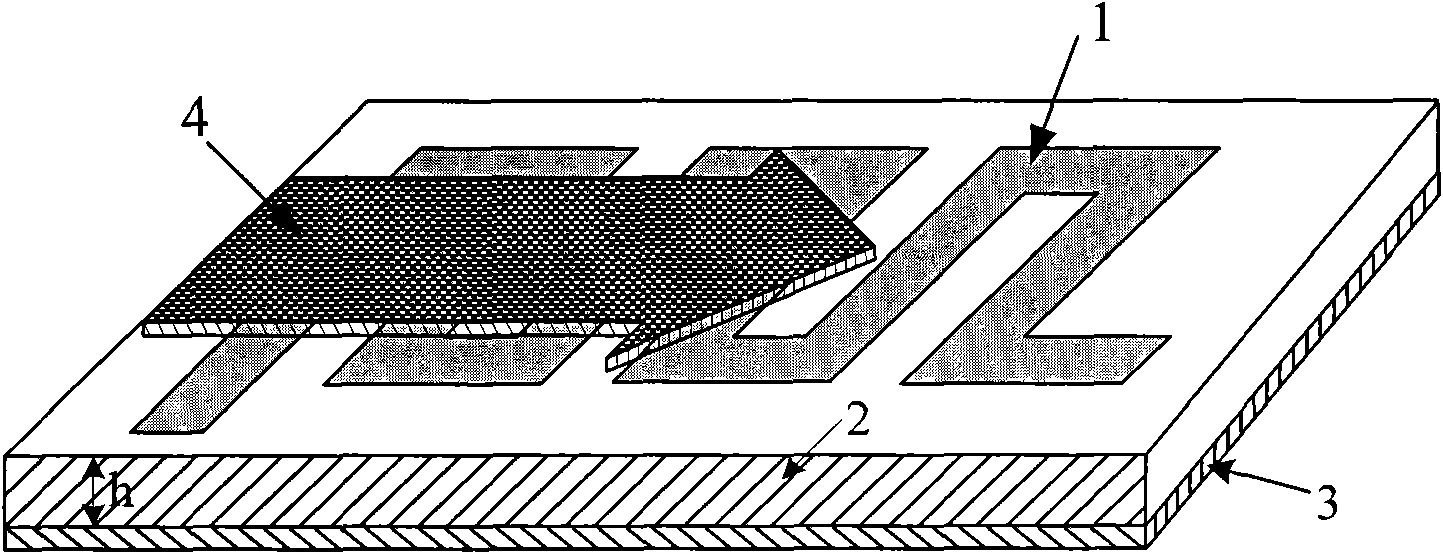

[0029] A V-shaped microstrip meander slow-wave structure, such as Figure 4 As shown, it includes a microstrip transmission line structure formed by a metal base plate 3 , a dielectric layer 2 and a planar metal line 1 . The dielectric layer 2 is located between the metal base plate 3 and the planar metal line 1 , and its shape is the same as that of the planar metal line 1 . The planar metal wire 1 is composed of a plurality of planar metal wire segments of the same shape and size connected end to end to form a zigzag structure; wherein two adjacent planar metal wire segments form a "V" shape or an inverted "V" shape, and a "V" shape or an inverted "V" "The included angle (2θ) of the font is less than 180 degrees.

[0030] After confirming that two adjacent sections of planar metal line segments form a "V" shape or an inverted "V" shape with equal angles (periodic structure), determine the relevant dimensions (unit: mm) of the above two implementations: a=0.72, b =0.36, p=0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com