X-type active light-resistant red azo dye and preparation method thereof

A technology of azo dyes and light fastness, which is applied in the direction of azo dyes, reactive dyes, organic dyes, etc., and can solve the problems of low dye utilization rate, wet rubbing fastness of dyed fabrics, low light fastness of light-colored varieties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

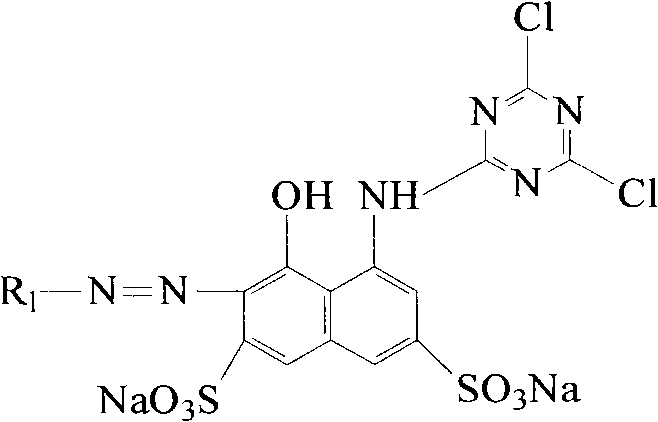

[0010] Embodiment 1, the synthesis of reactive photostable red XA

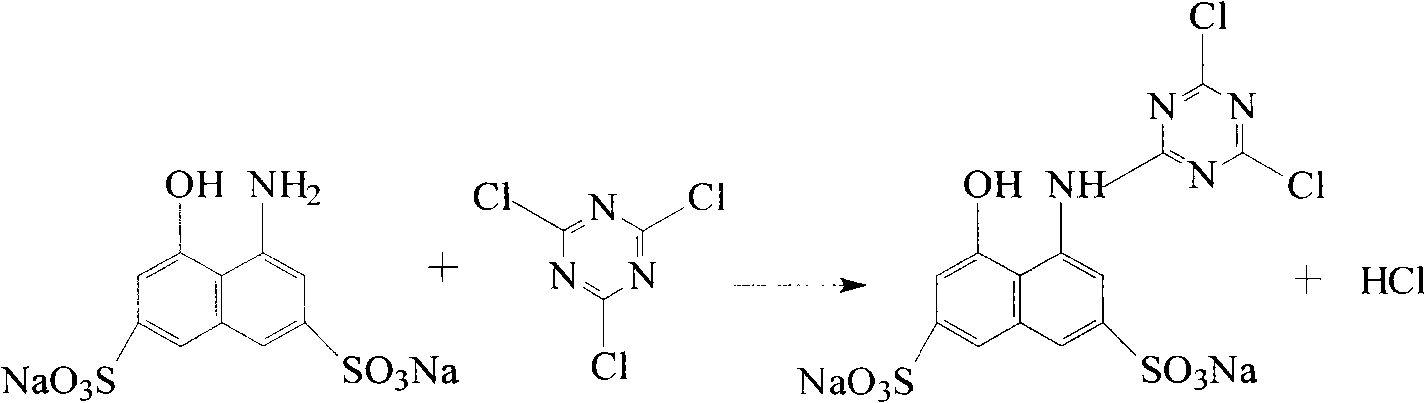

[0011] 1. Preparation of cyanuric chloride and H acid condensation reaction solution

[0012] In a 250mL four-neck flask equipped with a stirrer, dropping funnel and thermometer, add 15g of crushed ice, 0mL of water and 0.011mol of cyanuric chloride to make a slurry at 0°C for 30 minutes, then dropwise add pH=7 within 1 hour. ~8. For the H acid solution with a H acid content of 0.01mol, after the addition, keep the pH of the reaction solution at 2~3, continue to stir and react at 5~8°C for 3 hours, and use an amino indicator to detect the presence of H acid in the solution Afterwards, stop the reaction and filter to obtain a clarified condensate for later use. The reaction formula is as follows:

[0013]

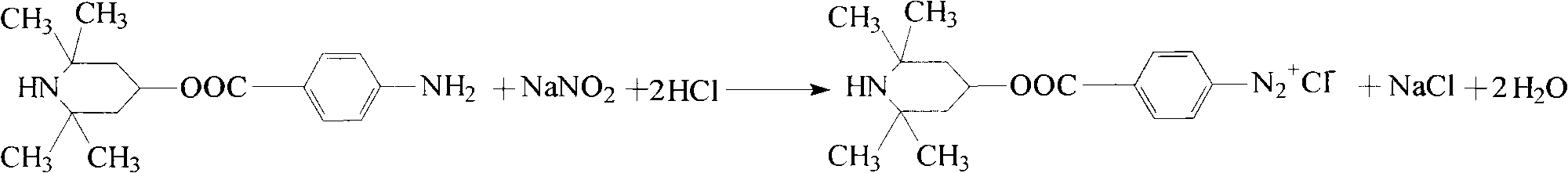

[0014] 2, Preparation of 4-(4-aminobenzoate group)-2,2,6,6-tetramethylpiperidine diazonium salt solution

[0015] Add 30mL of water, 0.01mol of 4-(4-aminobenzoate)-2,2,6,6-tetramethylpiperidine, 3.5mL ...

Embodiment 2

[0020] Embodiment 2, the synthesis of reactive photostable red XB

[0021] The molecular structure formula of reactive photostable red XB is as follows:

[0022]

[0023] The preparation process of reactive light fast red XB is the same as embodiment 1, just 4-(4-aminobenzoate group)-2,2,6,6-tetramethylpiperidine in embodiment 1 is replaced by 4-( 4-aminobenzamido)-2,2,6,6-tetramethylpiperidine to obtain reactive photostable red XB.

Embodiment 3

[0024] Embodiment 3, the synthesis of reactive light fast red XC

[0025] The molecular structure formula of reactive light fast red XC is as follows:

[0026]

[0027] The preparation process of reactive lightfast red XC is the same as in Example 1, but 4-(4-aminobenzoate group)-2,2,6,6-tetramethylpiperidine in Example 1 is replaced by 4-( 3-aminobenzoate group)-2,2,6,6-tetramethylpiperidine to obtain active photostable red XC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com