Smoke waste heat utilization system

A flue gas waste heat and flue technology, used in preheating, waste heat treatment, heat storage heaters, etc., can solve the problems of easy fouling and corrosion, increased flue resistance, affecting heat exchange effect, etc., and avoid working fluids. Leakage, low running resistance and small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

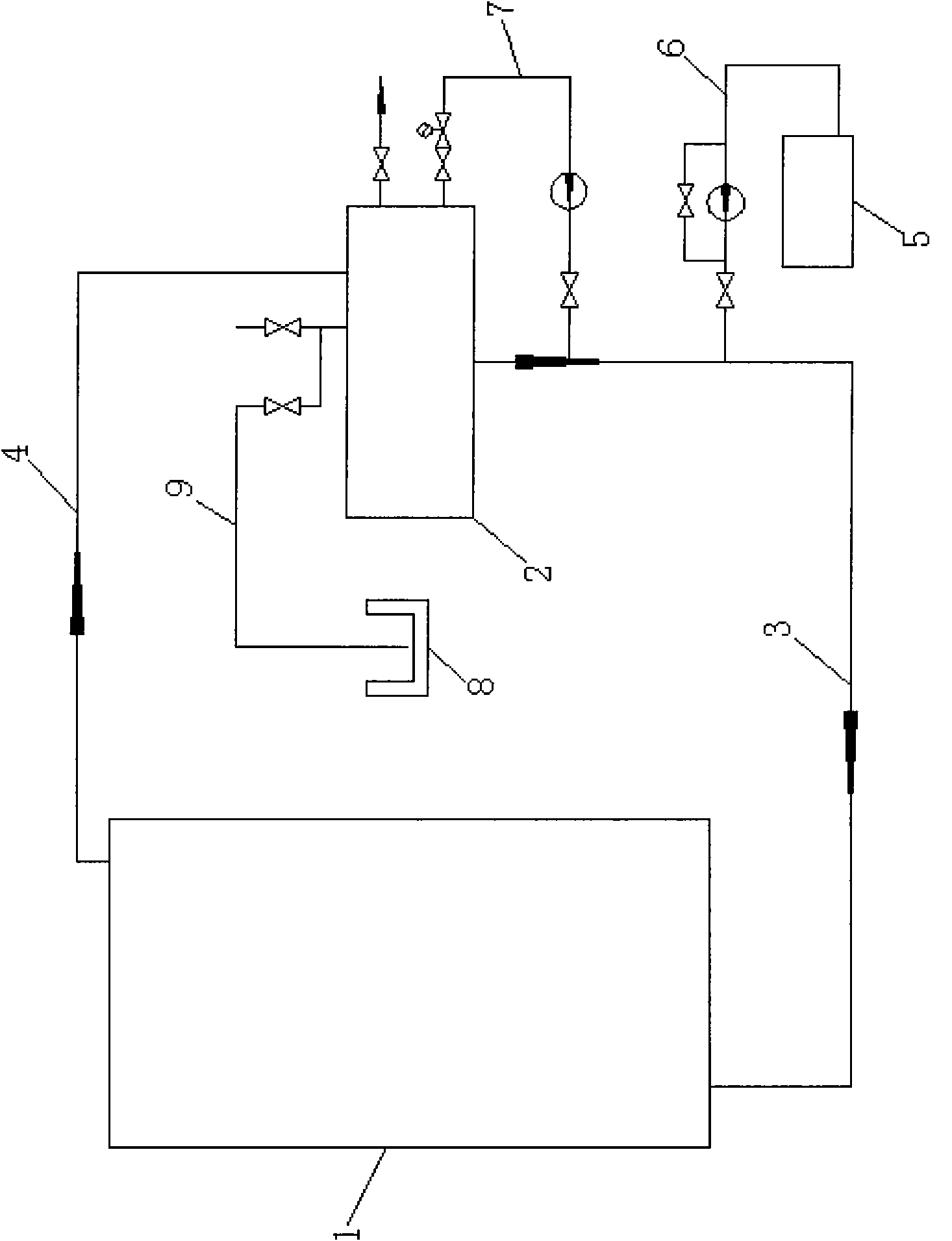

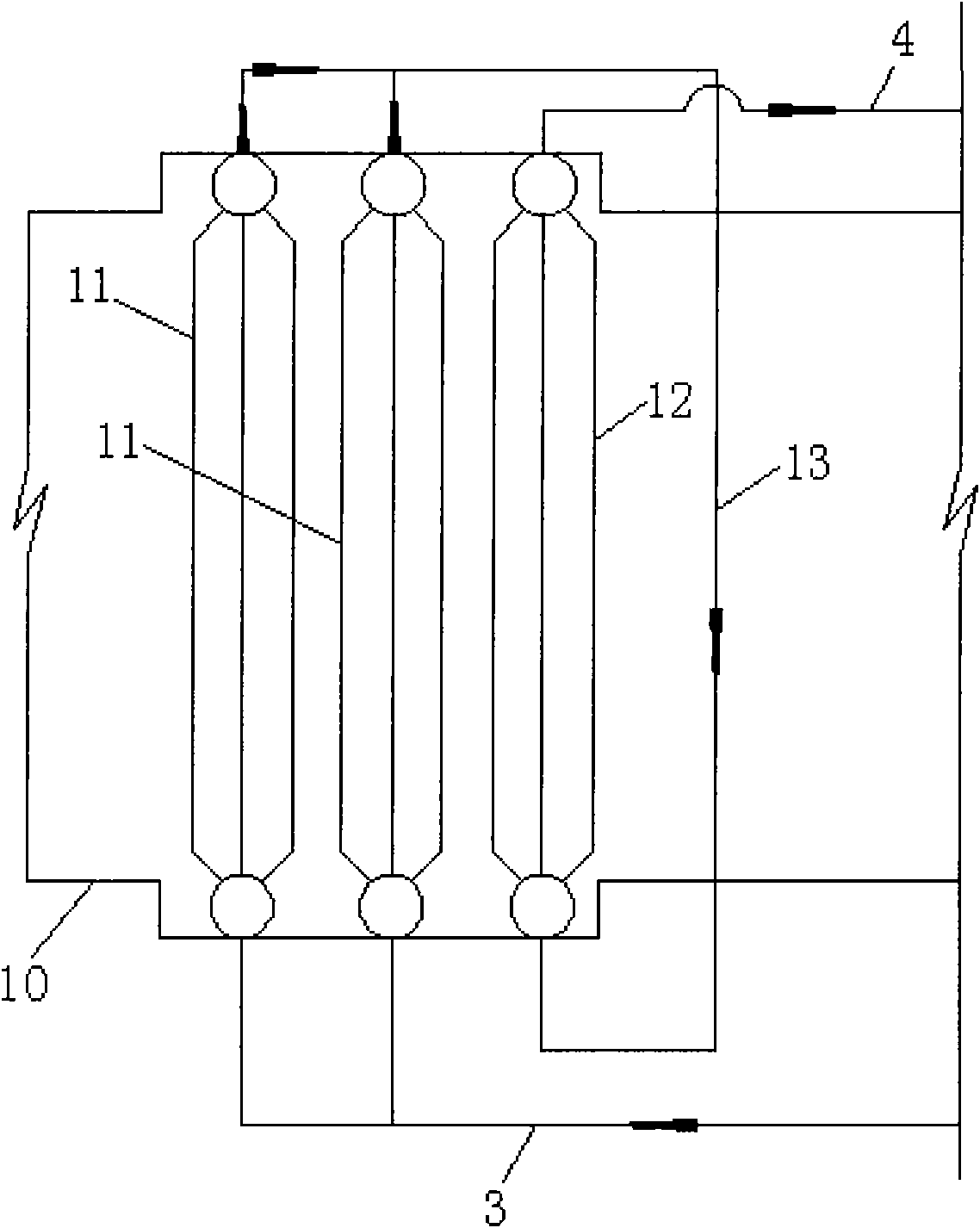

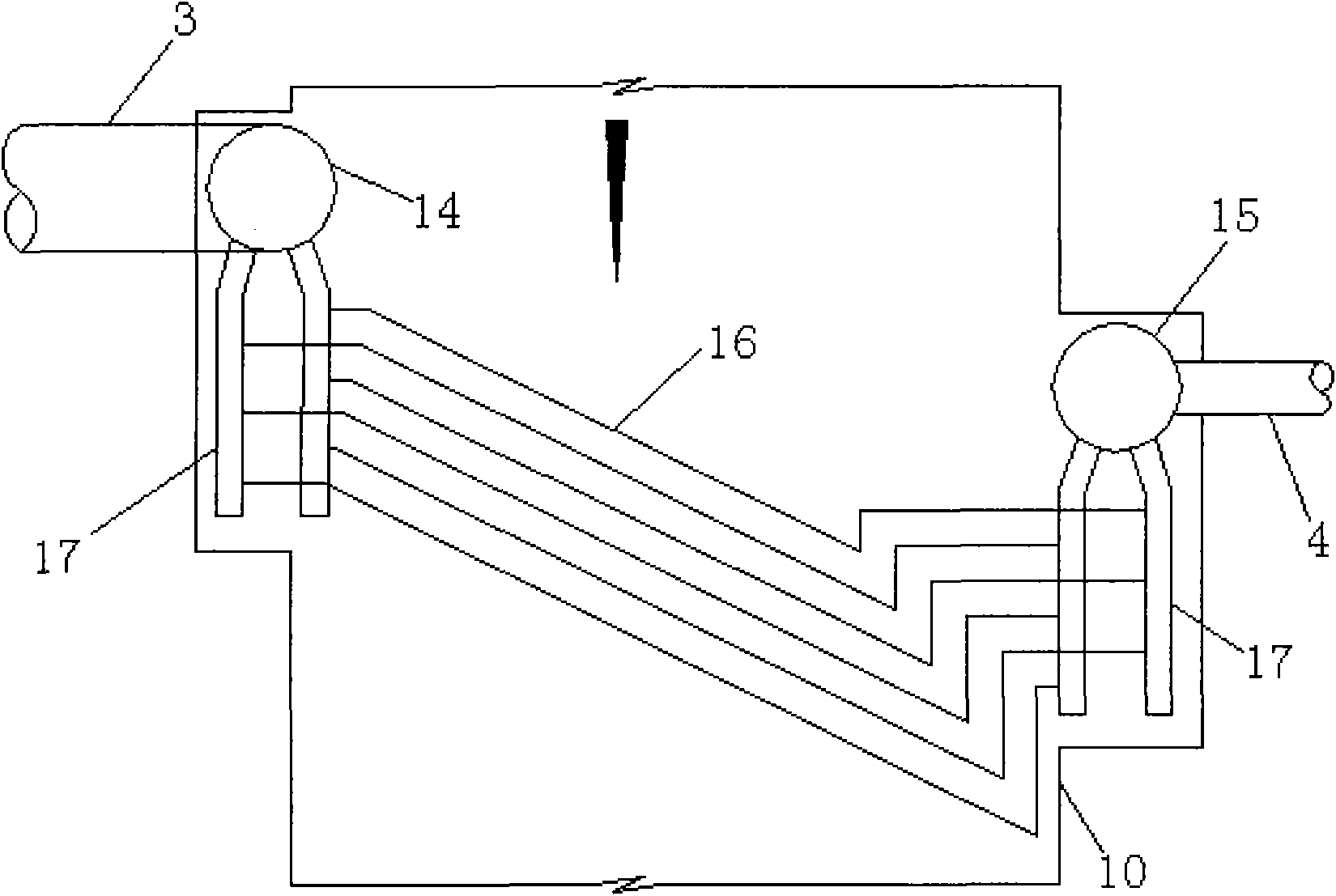

[0023] Embodiment: A flue gas waste heat utilization system, including a heat exchange boiling device 1 installed on a flue 10 and a heat exchange condensing device 2 for heating a heat medium, and the installation height of the heat exchange condensing device is higher than that of the heat exchange The installation height of the boiling device, the condensate outlet of the heat exchange condensing device and the liquid inlet of the heat exchange boiling device are connected with a condensate conduit 3, and the vapor outlet of the heat exchange boiling device is connected with the gas inlet of the heat exchange condensing device. The steam guide pipe 4, the heat transfer medium of the flue gas waste heat utilization system adopts chemical working fluids, which can be ammonia water, alcohol and other chemical working fluids with low boiling point and strong heat storage capacity. Specific chemical working fluids can be selected according to different waste heat parameters. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com