Process for the preparation of propylene random copolymers

A copolymer and propylene technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as adverse effects on catalytic activity, and achieve the effect of reducing the risk of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

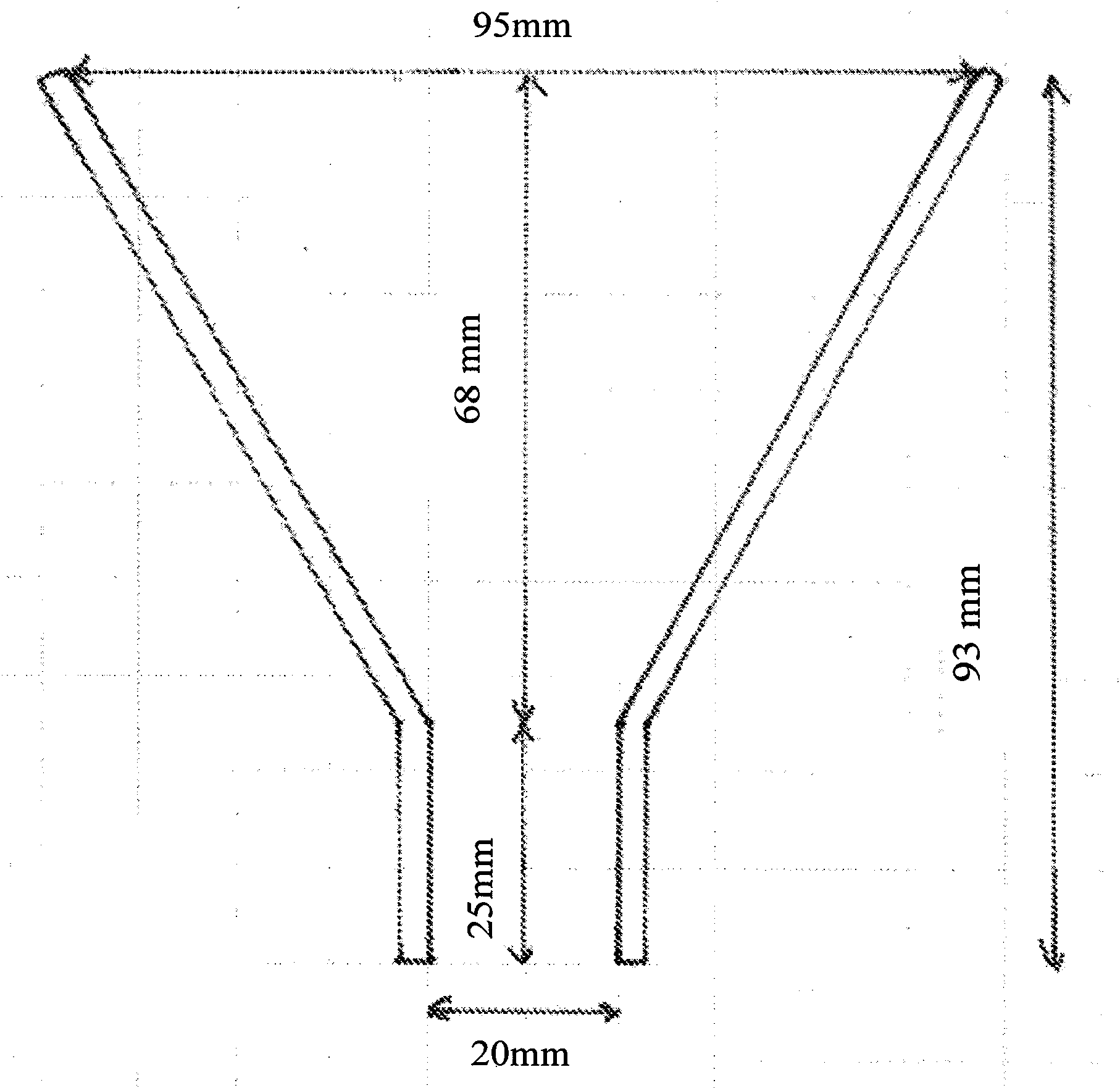

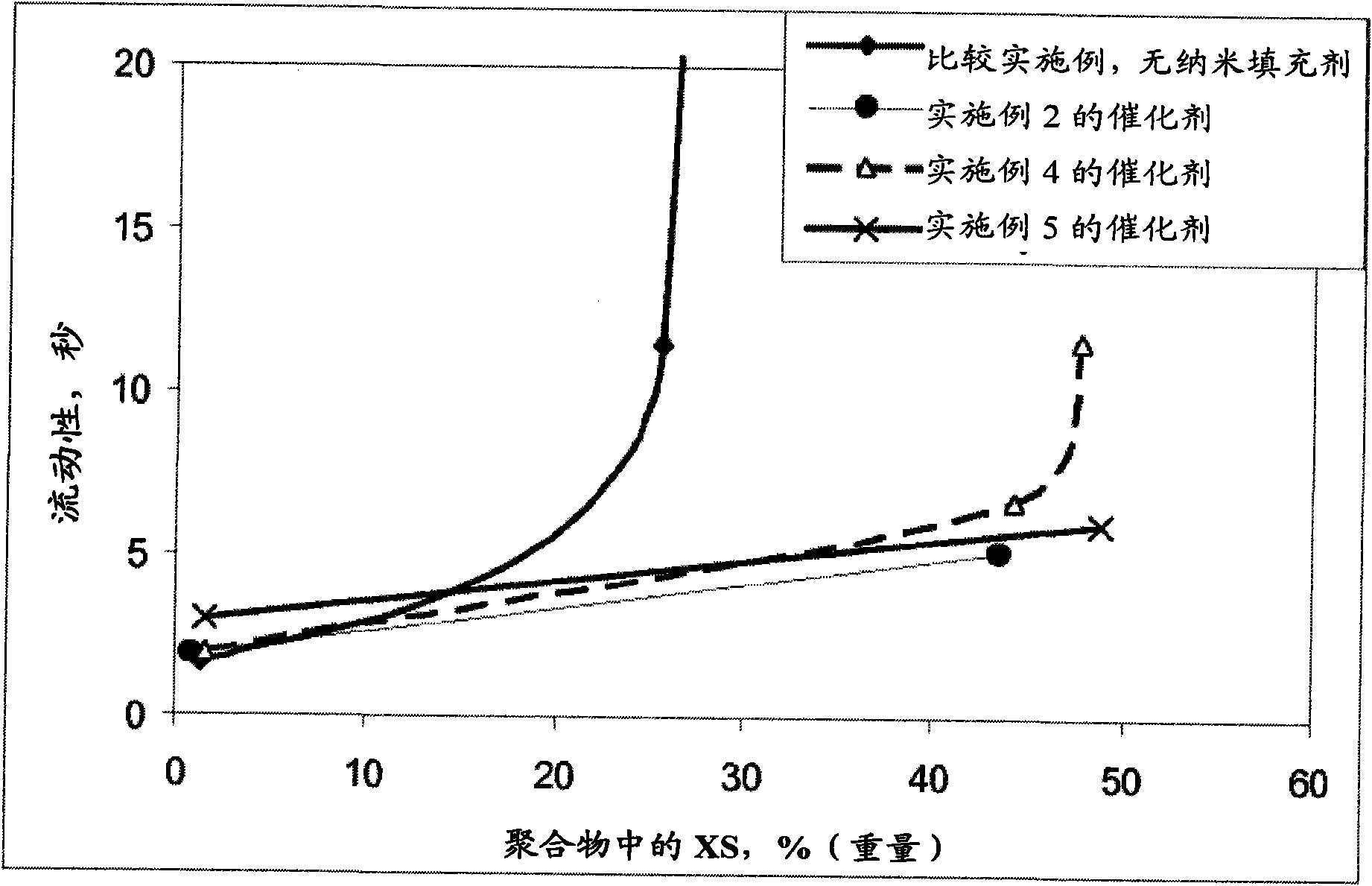

Image

Examples

Embodiment 1

[0216] Embodiment 1: the preparation of soluble Mg-complex

[0217] By mixing 55.8kg of 20% BOMAG (Mg(Bu) i,5 (October) 0,5 ) was added to 19.4kg of 2-ethylhexanol in a 150l steel reactor to prepare a magnesium complex solution. The temperature of the contents of the reactor was maintained below 20°C during the addition. The temperature of the reaction mixture was then raised to 60°C and maintained at this temperature with stirring for 30 minutes at which point the reaction was complete. Then 5.50 kg of 1,2-phthaloyl dichloride were added and the reaction mixture was stirred for a further 30 minutes at 60°C. After cooling to room temperature, a yellow solution was obtained.

Embodiment 2

[0218] Example 2: Catalyst with internal pore structure

[0219] 24 kg of titanium tetrachloride were placed in a 90 l steel reactor. Then, 0,190 kg of SiO provided by Nanostructured & Amorphous Inc. (NanoAmor) was added in two hours. 2 Nanoparticles (average particle size 80nm; surface area 440m 2 / g; bulk density 0.063 g / cm) mixture and 21.0 kg Mg-complex were added to the stirred reaction mixture. During the Mg-complex addition, the reactor contents were kept below 35°C.

[0220] 4.5 kg of n-heptane and 1.05 l of RohMax Additives GmbH's Viscoplex 1-254 (a polyalkylmethacrylate with a viscosity of 90mm at 100°C) were then mixed at room temperature. 2 / s, density at 15° C. of 0.90 g / ml) was added to the reaction mixture, which was kept stirring at this temperature for 60 minutes.

[0221] The temperature of the reaction mixture was then slowly raised to 90° C. over 60 minutes and stirred at this temperature for 30 minutes. After settling and siphoning, the solid was wash...

Embodiment 3A

[0224] Example 3A: Dense Catalyst Particles - No Internal Porosity

[0225] Same as Example 2, but without addition of SiO to the Mg-complex 2 nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com