A kind of polymer polycarbonate alloy material and preparation method thereof

An alloy material and polycarbonate technology, applied in the field of polymer polycarbonate alloy material and its preparation, can solve the problems of surface pattern, difficult processing, serious delamination and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

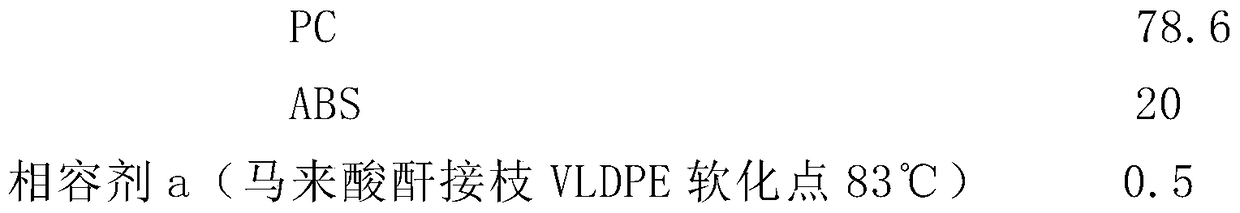

[0020] The raw materials of the polymer polycarbonate alloy material of the present invention include, in parts by weight:

[0021]

[0022]

[0023] First, after mixing PC and compatibilizer a at high speed, they are melted and pelletized by a twin-screw extruder at one time. The processing technology is as follows: the extrusion temperature of one-time melting is 220-245℃, which is specifically a zone of the twin-screw extruder. 220°C, 235°C in the second zone, 235°C in the third zone, 235°C in the fourth zone, 240°C in the fifth zone, 245°C in the sixth zone, 240°C in the seventh zone, 235°C in the eight zone, and screw speed 300r / min to obtain PC / PE-g -MAH;

[0024] Then, the obtained PC / PE-g-MAH particles are mixed with ABS, compatibilizer b, and antioxidant at high speed, and then melted and pelletized by a twin-screw extruder. The processing technology is as follows: The output temperature is 210~230℃, specifically the twin screw extruder is 210℃ in the first zone, 225℃ in ...

Embodiment 2

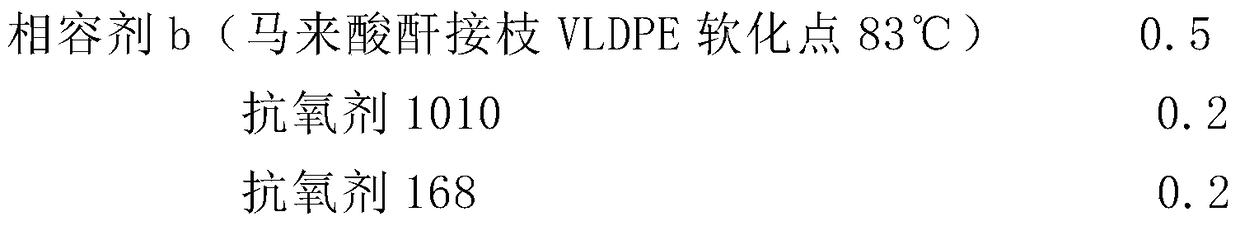

[0031] The raw materials of the polymer polycarbonate alloy material of the present invention include, in parts by weight:

[0032]

[0033] First, after mixing PC and compatibilizer a at high speed, they are melted and pelletized by a twin-screw extruder at one time. The processing technology is as follows: the extrusion temperature of one-time melting is 220-245℃, which is specifically a zone of the twin-screw extruder. 220°C, 235°C in the second zone, 235°C in the third zone, 235°C in the fourth zone, 240°C in the fifth zone, 245°C in the sixth zone, 240°C in the seventh zone, 235°C in the eight zone, and screw speed 300r / min to obtain PC / PE-g -MAH.

[0034] Then, the obtained PC / PE-g-MAH particles are mixed with ABS, compatibilizer b, and antioxidant at high speed, and then melted and pelletized by a twin-screw extruder. The processing technology is as follows: The output temperature is 210~230℃, specifically the twin screw extruder is 210℃ in the first zone, 225℃ in the secon...

Embodiment 3

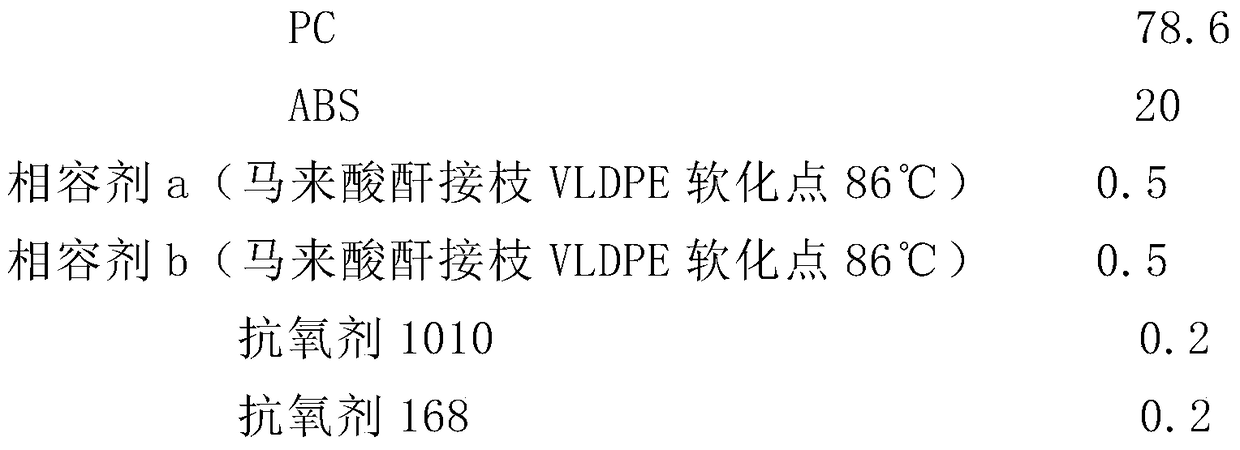

[0041] The raw materials of the polymer polycarbonate alloy material of the present invention include, in parts by weight:

[0042]

[0043] First, after mixing PC and compatibilizer a at high speed, they are melted and pelletized by a twin-screw extruder at one time. The processing technology is as follows: the extrusion temperature of one-time melting is 180~245℃, which is specifically a zone of the twin screw extruder. 180°C, 190°C in the second zone, 200°C in the third zone, 235°C in the fourth zone, 240°C in the fifth zone, 245°C in the sixth zone, 240°C in the seventh zone, 235°C in the eight zone, and screw speed 300r / min to obtain PC / PE-g -MAH.

[0044] Then, the obtained PC / PE-g-MAH particles are mixed with ABS, compatibilizer b, and antioxidant at high speed, and then melted and pelletized by a twin-screw extruder. The processing technology is as follows: The output temperature is 210~230℃, specifically the twin screw extruder is 210℃ in the first zone, 225℃ in the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com