Catalyst compounding system for improving rigidity and toughness balance of base resin special for PPR pipes

A basic resin and catalyst technology, applied in the field of catalysis, can solve the problems of non-particle shape of polymer, large amount of catalyst, high production cost, etc., achieve good rigidity and heat distortion temperature, reduce attenuation, and avoid precipitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

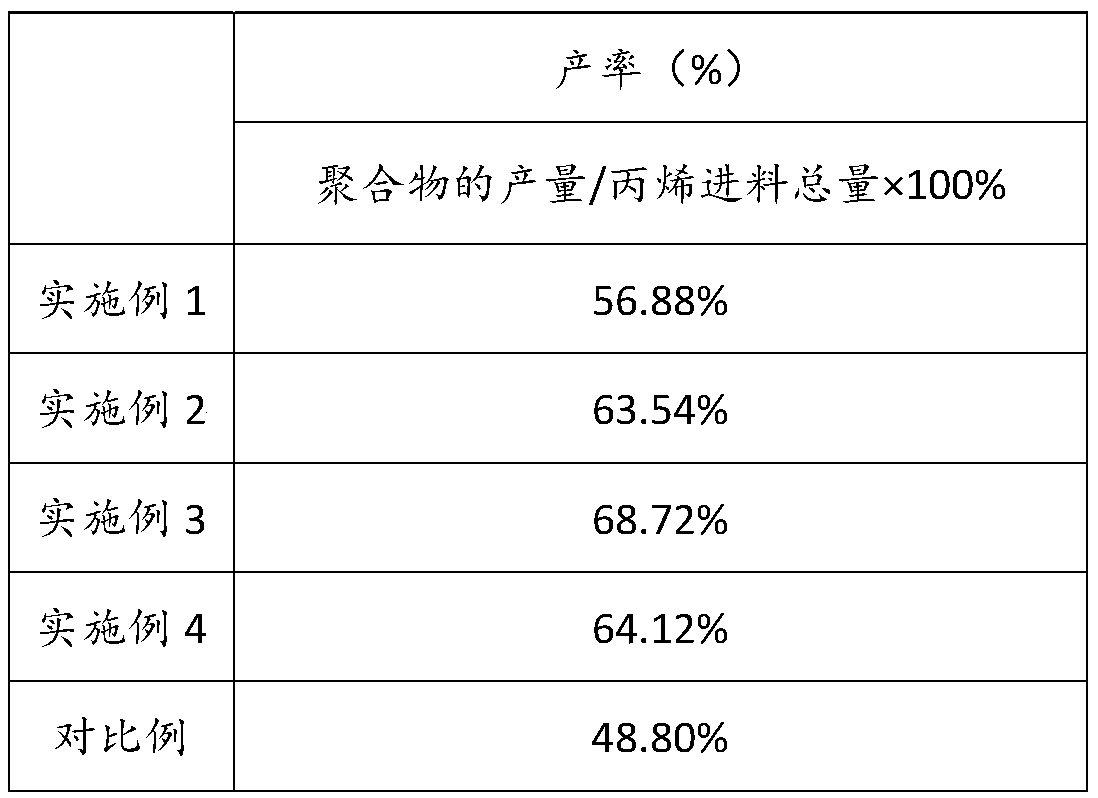

Embodiment 1

[0048] The invention provides a catalyst compounding system for improving the rigidity-toughness balance of the special base resin for PPR pipes, including a main catalyst, a co-catalyst, an external electron donor and an internal electron donor, wherein the main catalyst is MgCl 2 / SBA-15 composite carrier supports titanium tetrachloride, the cocatalyst is triethylaluminum, the internal electron donor is diether, and the external electron donor is dimethyloxysilane;

[0049] MgCl 2 The preparation method of / SBA-15 composite carrier is as follows:

[0050] MgCl under nitrogen atmosphere 2 Dissolve in a certain amount of THF, heat to reflux, stir, until MgCl 2 After completely dissolving to form a colorless transparent liquid, add MgCl 2 Dopamine with a mass of 1 / 100, stirred for 12 hours, then added a certain amount of roasted SBA-15 carrier, then slowly lowered the temperature to 40°C, stirred for 6 hours, and waited for MgCl 2 After fully reacting with the SBA-15 carrie...

Embodiment 2

[0059] The invention provides a catalyst compounding system for improving the rigidity-toughness balance of the special base resin for PPR pipes, including a main catalyst, a co-catalyst, an external electron donor and an internal electron donor, wherein the main catalyst is MgCl 2 / SBA-15 composite carrier supports titanium tetrachloride, the cocatalyst is triethylaluminum, the internal electron donor is diether, and the external electron donor is dimethyloxysilane;

[0060] MgCl 2 The preparation method of / SBA-15 composite carrier is as follows:

[0061] MgCl under nitrogen atmosphere 2 Dissolve in a certain amount of THF, heat to reflux, stir, until MgCl 2 After completely dissolving to form a colorless transparent liquid, add MgCl 2 Dopamine with a mass of 1 / 100, stirred for 16 hours, then added a certain amount of roasted SBA-15 carrier, then slowly lowered the temperature to 40°C, stirred for 4 hours, and waited for MgCl 2 After fully reacting with the SBA-15 carrie...

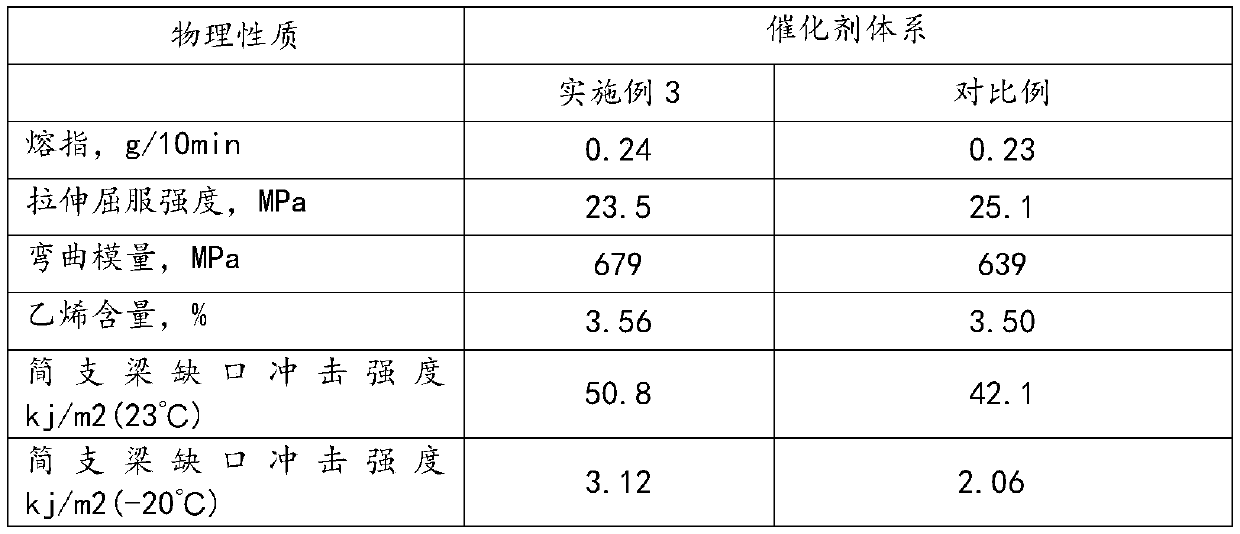

Embodiment 3

[0070] The invention provides a catalyst compounding system for improving the rigidity-toughness balance of the special base resin for PPR pipes, including a main catalyst, a co-catalyst, an external electron donor and an internal electron donor, wherein the main catalyst is MgCl 2 / SBA-15 composite carrier supports titanium tetrachloride, the cocatalyst is triethylaluminum, the internal electron donor is diether, and the external electron donor is dimethyloxysilane;

[0071] MgCl 2 The preparation method of / SBA-15 composite carrier is as follows:

[0072] MgCl under nitrogen atmosphere 2 Dissolve in a certain amount of THF, heat to reflux, stir, until MgCl 2 After completely dissolving to form a colorless transparent liquid, add MgCl 2 Dopamine with a mass of 1 / 100, stirred for 14 hours, then added a certain amount of roasted SBA-15 carrier, then slowly lowered the temperature to 40°C, stirred for 2.5 hours, and waited for MgCl 2 After fully reacting with the SBA-15 carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com