Method for producing medicinal granules with hypotensive effect by utilizing by-product obtained by producing purple sweet potato starch

A technology of purple potato starch and by-products, applied in the field of granule drinks, can solve problems such as waste excretion, waste of materials, environmental pollution, etc., and achieve the effects of saving resources, reducing use costs, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Wash the purple sweet potato and crush it with a high-speed tissue grinder. During the crushing process, add water according to the weight ratio of purple sweet potato and water at 1:3. Then filter with double-layer gauze to obtain filter residue and filtrate. Add water to the filter residue and water in a ratio of 1:1 by weight, then use a colloid mill to further grind to a particle size of less than 15 μm, and then spray dry to obtain a powdery solid substance.

[0024] 2. The powdery solid substance obtained in step 1 and xylitol are uniformly mixed according to the ratio of 10:3 by weight to obtain the granule drink with antihypertensive effect.

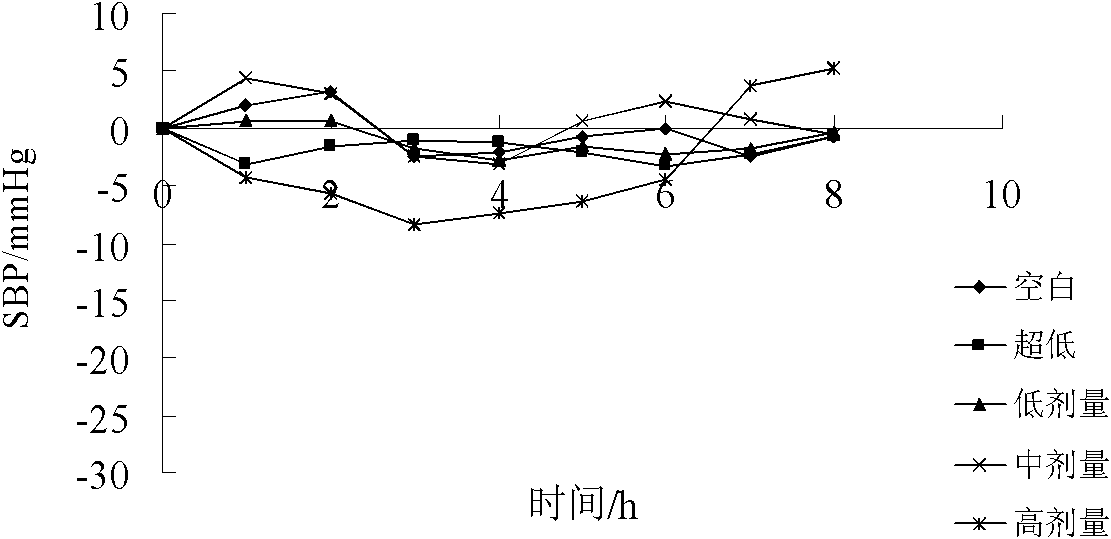

[0025] 3. Animal experiments: 24 12-week-old male SHR rats with a body weight of 260±15 g were given free access to food and water, kept at an ambient temperature of 23±1° C. and a relative humidity of (60±5)%, and pre-raised for one week. Rats were randomly divided into 3 groups, 8 in each group. Among them, one grou...

Embodiment 2

[0029] 1. Wash the purple sweet potato and crush it with a high-speed tissue grinder. During the crushing process, add water according to the weight ratio of purple sweet potato and water at 1:3. Then filter to obtain filter residue and filtrate. The filtrate is left to settle, the precipitate is starch, and the supernatant is a water-soluble substance, and the supernatant is separated from the precipitate by siphoning. The supernatant after separating the starch is spray-dried to obtain a powdery solid substance.

[0030] 2. The powdery solid substance obtained in step 1 and xylitol are uniformly mixed according to the ratio of 10:3 by weight to obtain the granule drink with antihypertensive effect.

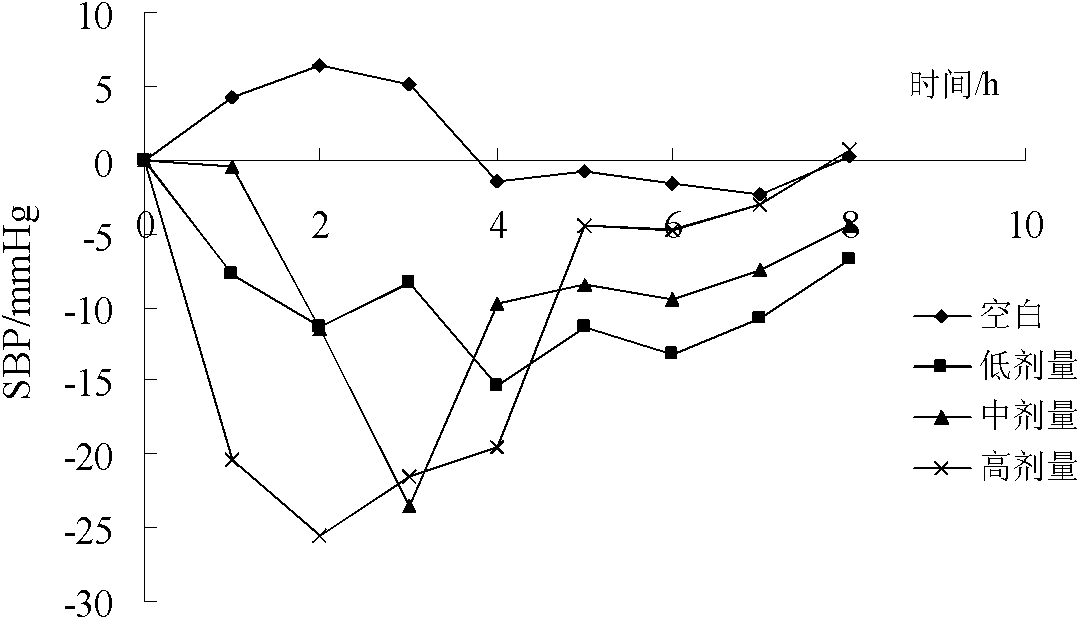

[0031] 3. Animal experiment: 40 12-week-old male SHR rats, with a body weight of 260±15g, had free access to food and water, kept at an ambient temperature of 23±1° C., and a relative humidity of (60±5)%, and were pre-raised for one week. Rats were randomly divided into 5 grou...

Embodiment 3

[0035] 1. Wash the purple sweet potato and crush it with a high-speed tissue grinder. During the crushing process, add water according to the weight ratio of purple sweet potato and water at 1:3. Then filter to obtain filter residue and filtrate. The filtrate is left to settle, the precipitate is starch, and the supernatant is water-soluble matter. The supernatant after separating the starch is mixed with the filter residue, finely ground by a colloid mill to a particle size of less than 15 μm, and then spray-dried to obtain a powdery solid substance.

[0036] 2. The powdery solid substance obtained in step 1 and xylitol are uniformly mixed according to the ratio of 10:3 by weight to obtain the granule drink with antihypertensive effect.

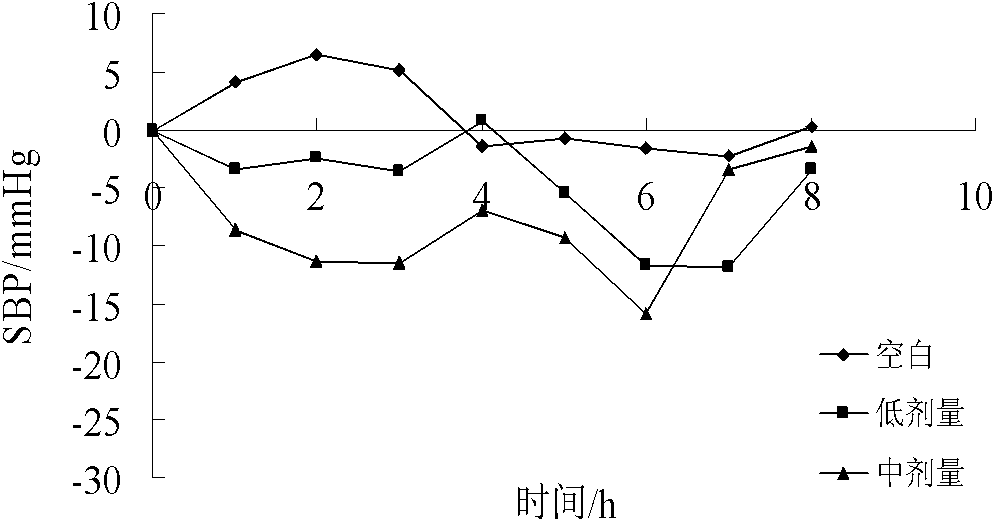

[0037] 3. Animal experiment: 32 12-week-old male SHR rats, weighing 260±15g, had free access to food and water, kept at an ambient temperature of 23±1° C., and a relative humidity of (60±5)%, and were pre-raised for one week. Rats were ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com