Tissue-like manufacture die based on spheroid elementary unit and preparation process

A technology of basic unit and preparation process, applied in the direction of prosthesis, medical science, etc., can solve the problem that the stent manufacturing method cannot be satisfied, and achieve the effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

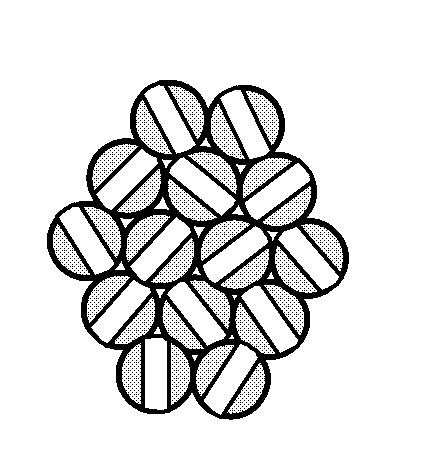

[0017] refer to figure 1 As shown, this type of tissue has an internal channel structure, which is used to simulate the blood vessels, material flow, exchange, etc. between natural cells. The spherical unit has independent channels that simulate the cell structure, and can be connected with other units to form a larger Scaffold or class tissue.

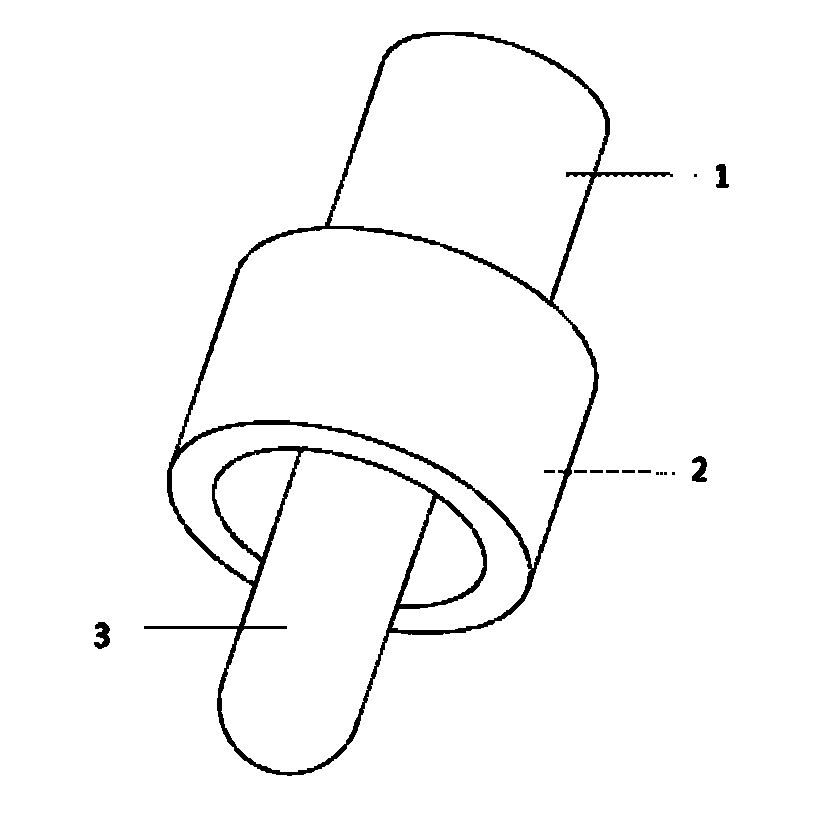

[0018] refer to figure 2 , image 3 The upper and lower mold cavities of the mold for pressing the spherical unit are respectively provided with positioning pins and positioning holes. There is a certain gap between the two. The positioning pins can also be used to press the inner channel of the spherical unit. The upper die has an upper hemispherical cavity and positioning guide posts; the lower die has a lower hemispherical cavity and a positioning counterbore.

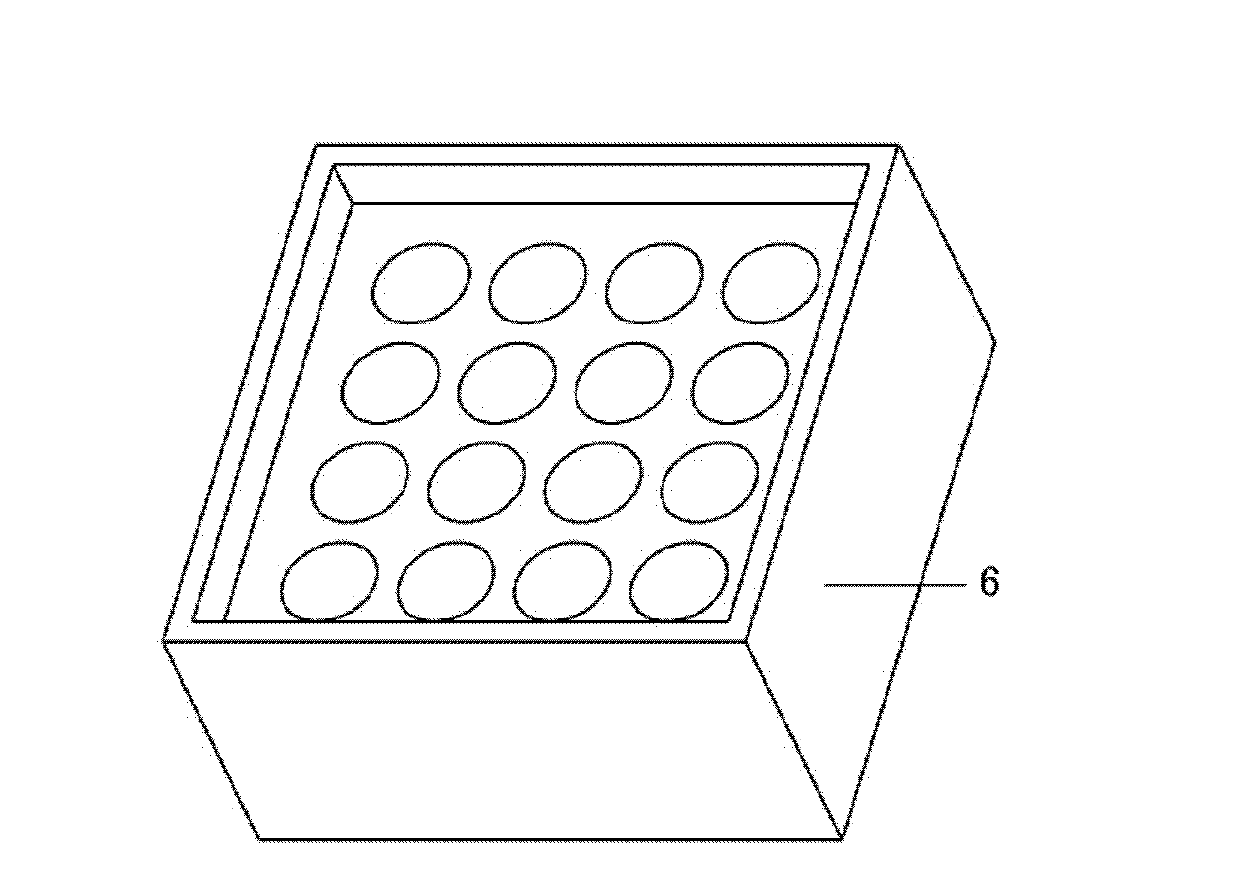

[0019] refer to Figure 4 As shown, the mold base is used to install the upper and lower mold cavities. Specific process combined with image 3 The description is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com