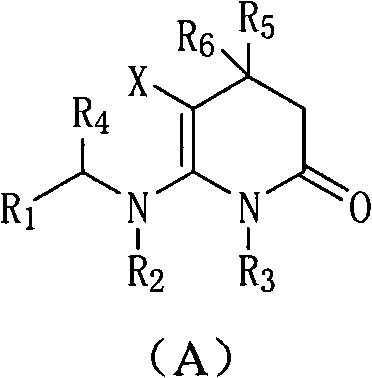

3,4-dihydropyridine-2-ketone heterocyclic compound and application thereof

A compound, six-membered heterocycle technology, applied in the field of nicotinic compounds, can solve problems such as limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

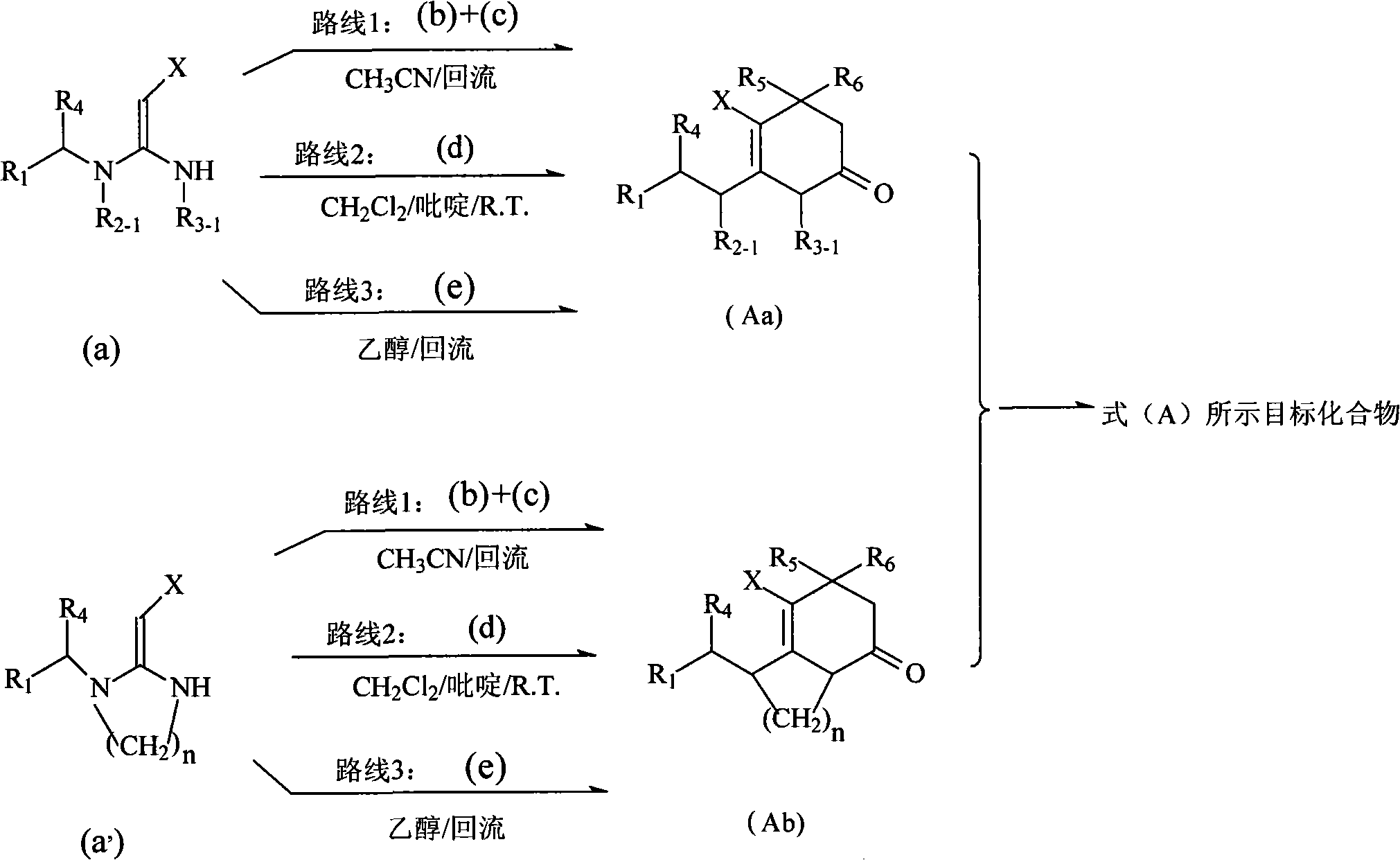

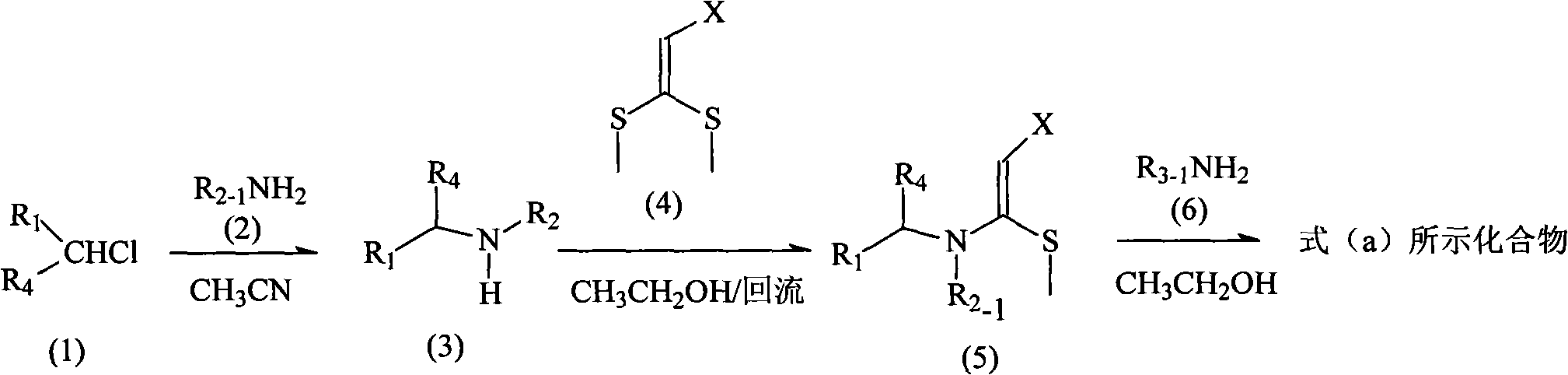

Method used

Image

Examples

Embodiment 1

[0092] Synthesis of compound (Aa-1):

[0093]

[0094] Under nitrogen protection, add 94.38mg (0.39mmol) compound (a-1), 68mg (0.47mmol) compound (b), 1mL anhydrous acetonitrile, 0.05mL (0.47mmol) compound (c) to a 10mL Schlenk tube successively -1), 0.005 mL (0.04 mmol) triethylamine. The temperature of the reaction solution was slowly raised to 80°C-90°C under stirring, and the reaction was stopped after reflux for 4 hours. A large amount of solvent was removed by a rotary evaporator, and the reaction solution was concentrated and then directly separated by column chromatography (eluent: ethyl acetate) to obtain 100 mg of light yellow solid powder. The yield was 69%. Melting point: 213°C-214°C.

[0095] Note: All reagents, reaction vials and condenser tubes in this reaction were dried, and benzaldehyde was redistilled.

[0096] 1H NMR (400MHz, DMSO): δ8.95(s, 1H), 8.17(d, J=2.8Hz, 1H), 7.29-7.26(m, 3H), 7.12(d, J=8.0Hz, 1H), 7.10-7.08(m, 2H), 4.95(t, J=4.4Hz, 1H), 4...

Embodiment 2

[0099] Synthesis of compound (Aa-2):

[0100]

[0101] Under nitrogen protection, add 99.84mg (0.39mmol) compound (a-1), 68mg (0.47mmol) compound (b), 1mL anhydrous acetonitrile, 0.05mL (0.47mmol) compound (c) to a 10mL Schlenk tube successively -2), 0.005 mL (0.04 mmol) triethylamine. The temperature of the reaction solution was slowly raised to 80°C-90°C under stirring, and the reaction was stopped after reflux for 4 hours. A large amount of solvent was removed by a rotary evaporator, and the reaction solution was concentrated and separated by column chromatography (eluent: ethyl acetate) to obtain 96 mg of light yellow solid powder. The yield is 66%. Melting point: 83°C-84°C.

[0102] Note: All reagents, reaction flasks and condenser tubes in this reaction were dried, and furfural was redistilled.

[0103] 1 H NMR (400MHz, DMSO): δ8.95(s, 1H), 8.18(d, J=2.8Hz, 1H), 7.74(d, J=7.2, 1H), 7.21(d, J=8.0Hz, 1H ), 7.10-7.08(m, 2H), 4.89(t, J=3.2Hz, 1H), 4.83(d, J=2.4Hz, 2...

Embodiment 3

[0106] Synthesis of compound (Aa-3):

[0107]

[0108] Under nitrogen protection, add 86.58mg (0.39mmol) compound (a-2), 68mg (0.47mmol) compound (b), 1mL anhydrous acetonitrile, 61.57mg (0.47mmol) compound (c) to a 10mL Schlenk tube successively -3), 0.005 mL (0.04 mmol) triethylamine. The temperature of the reaction solution was slowly raised to 80°C-90°C under stirring, and the reaction was stopped after reflux for 4 hours. A large amount of solvent was removed by a rotary evaporator, and the reaction solution was concentrated and separated by column chromatography (eluent: ethyl acetate) to obtain 112 mg of light yellow solid powder. The yield was 76%. Melting point: 203°C-204°C.

[0109] Note: All reagents, reaction vials and condenser tubes for this reaction were dried.

[0110] 1 H NMR (400MHz, DMSO): δ8.98(s, 1H), 8.28(d, J=2.8Hz, 1H), 7.64(d, J=7.2, 1H), 7.29-7.26(m, 3H), 7.12 (d, J=8.0Hz, 1H), 5.12(t, J=3.2Hz, 1H), 4.86(d, J=2.8Hz, 2H), 3.93-3.83(m, 2H), 2.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com