Viscosity-reducing and scale-controlling uniform mixing method for crude oil mixed liquor and viscosity-reducing and scale-controlling uniform mixer thereof

A mixed liquid and homomixer technology, which is applied in the direction of water treatment and refining, can solve the problems of poor treatment efficiency and effect, increased dosing volume, excessive water content in crude oil transportation, etc., to prevent scaling and reduce dosing volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further description will be made below in conjunction with accompanying drawings and specific examples

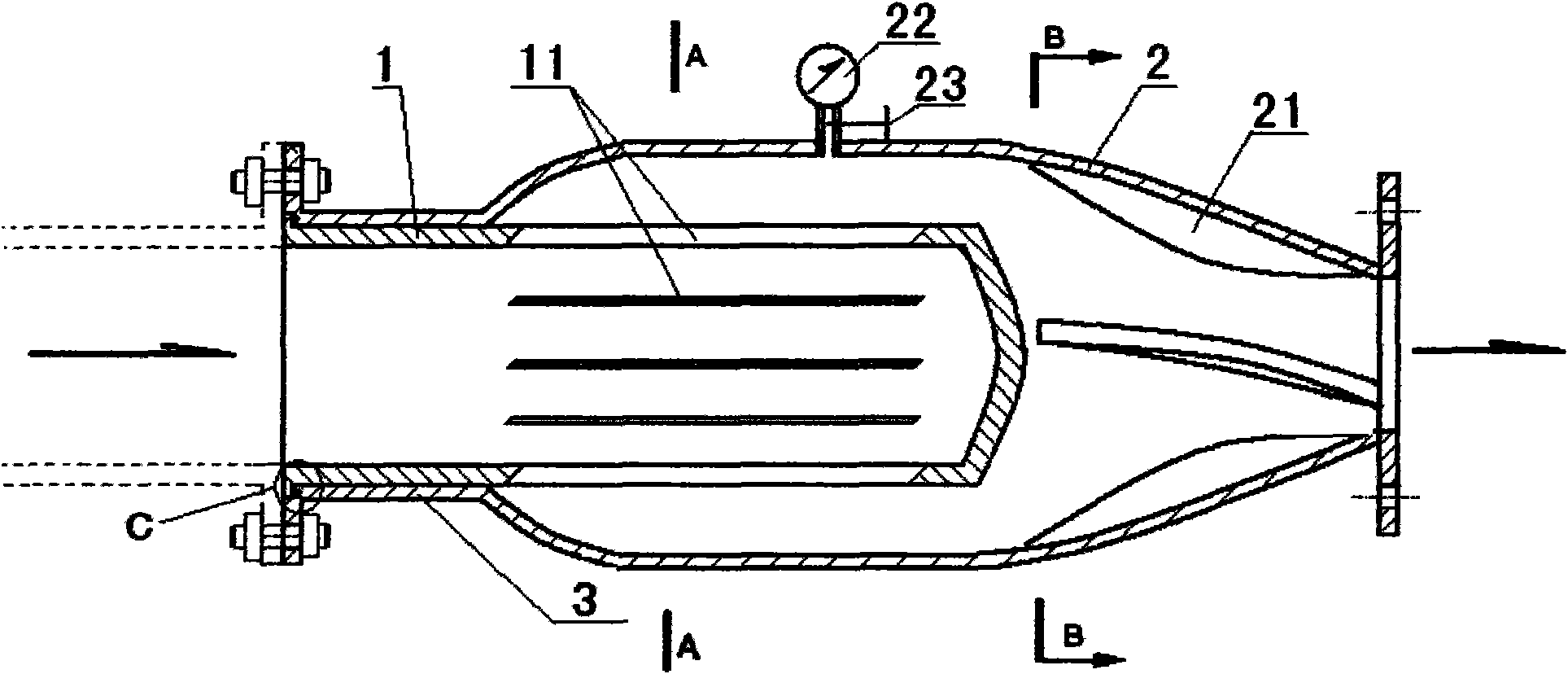

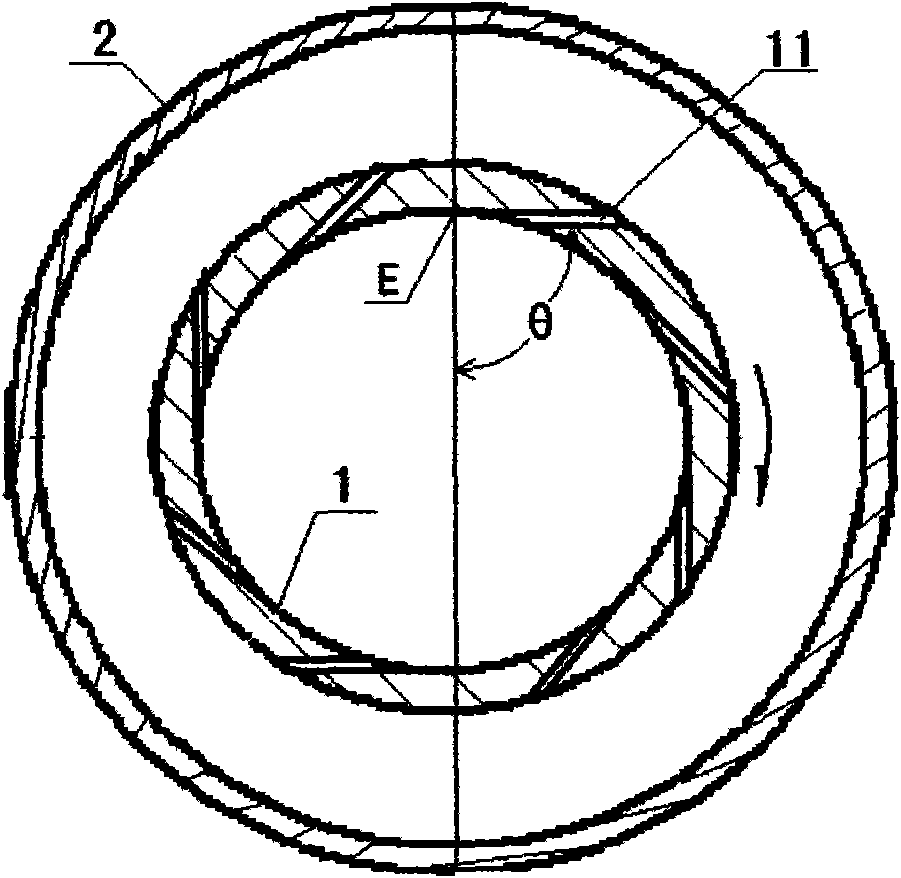

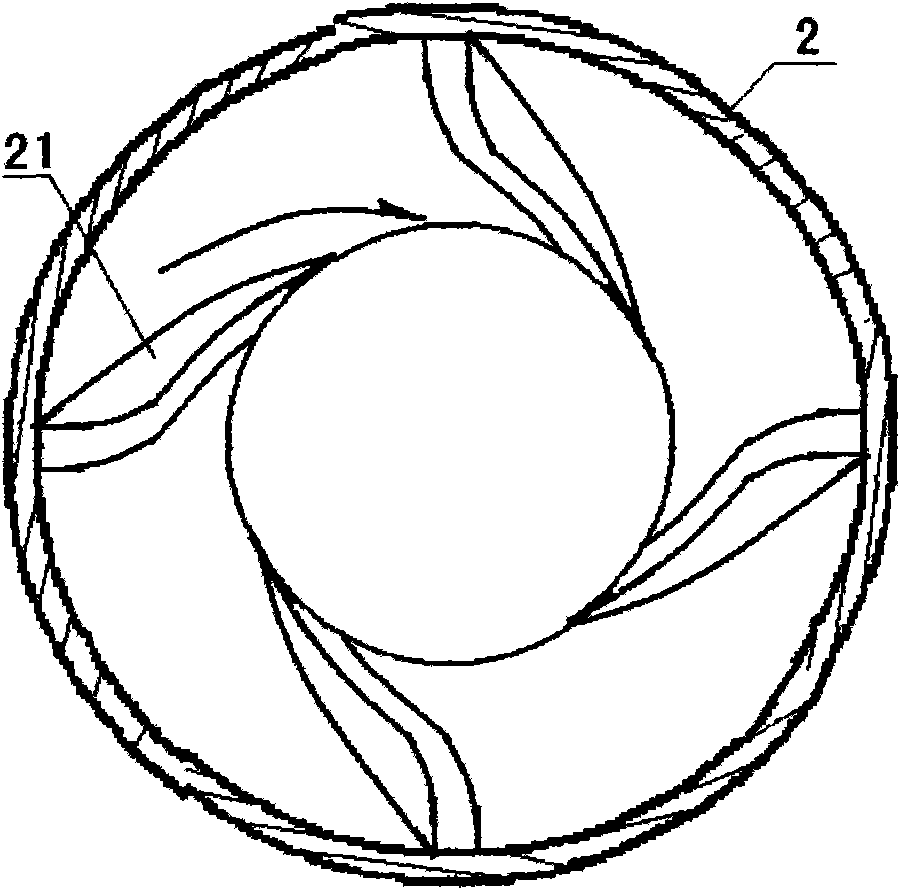

[0027] The viscosity-reducing and anti-scaling homogeneous mixing method of the crude oil mixed liquid of the invention utilizes high-speed shearing, rapid pressure relief and forced swirling to carry out the viscosity-reducing, anti-scaling and homogeneous mixing of the crude oil mixed liquid. That is: the crude oil mixture enters the high-pressure barrel after being pressurized by the high-pressure pump, and is sheared by the uniformly distributed axial slits made on the outer periphery of the high-pressure barrel under high pressure. barrel, and then flow out after being forced to swirl by the deflector plate made on the inner circumference of the outlet end of the low-pressure barrel. When the crude oil mixture passes through the slit, it also passes through the slit end wall inclined toward the outlet to guide the flow toward the outlet; seam for rotation guida...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap