Waveguide coupler chip for semiconductor laser

A technology of lasers and couplers, applied in the coupling of optical waveguides, etc., can solve the problems of low matching degree of doped waveguides 5, limited coupling efficiency, complicated production, etc., and achieve the effects of flexible design, high-efficiency coupling, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

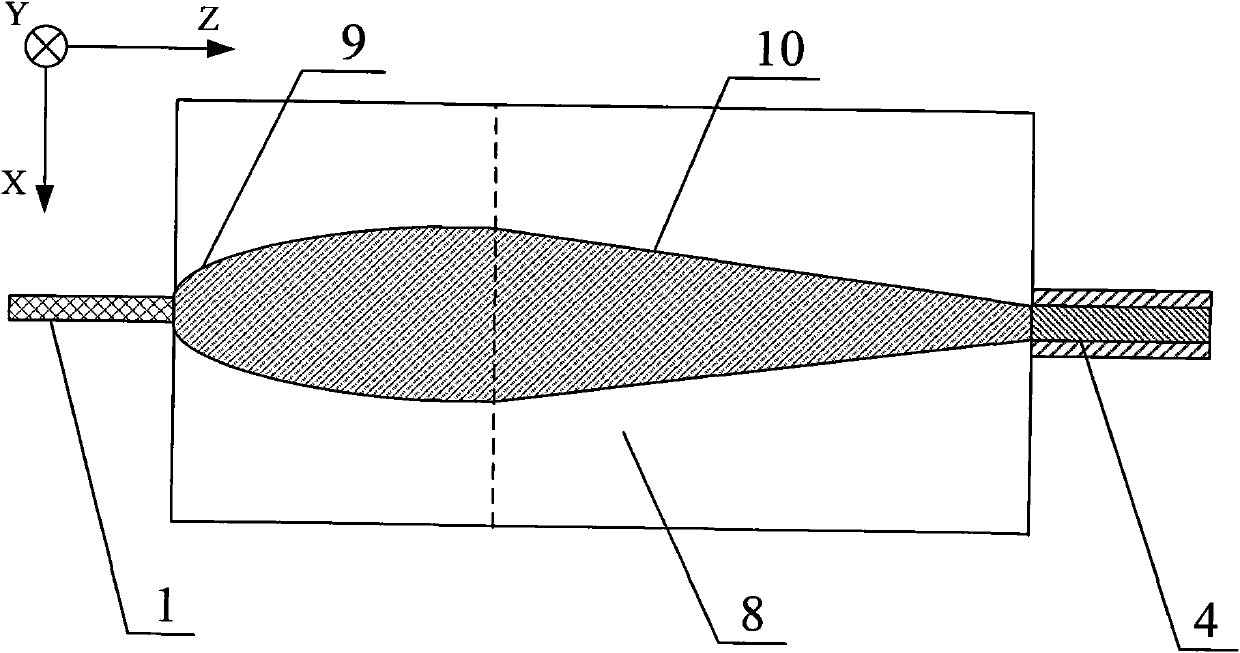

[0017] Such as Figure 4 As shown, the present invention realizes the coupling of the end surface emitting semiconductor laser 1 and the optical fiber 4 by doping the optical waveguide chip 8 once.

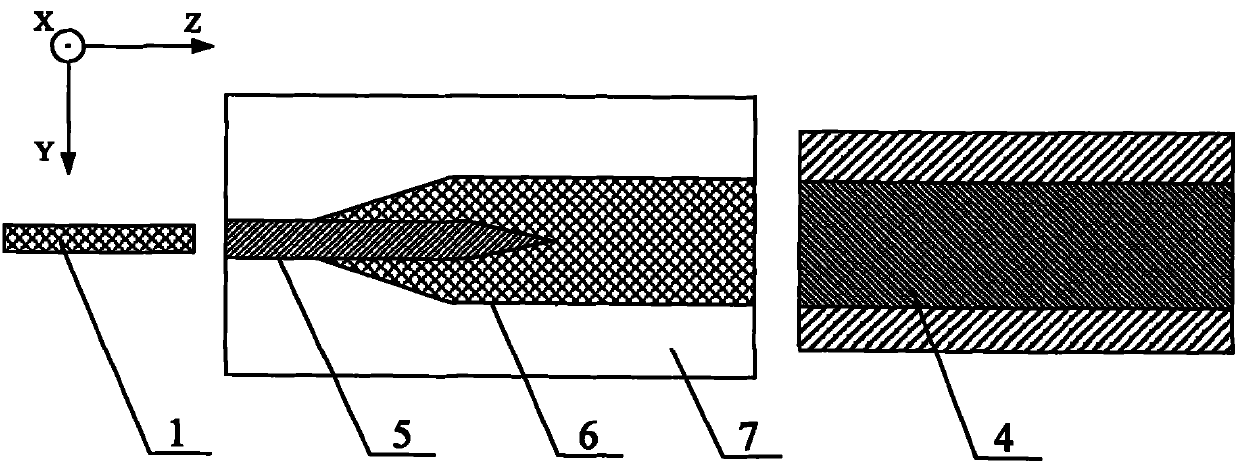

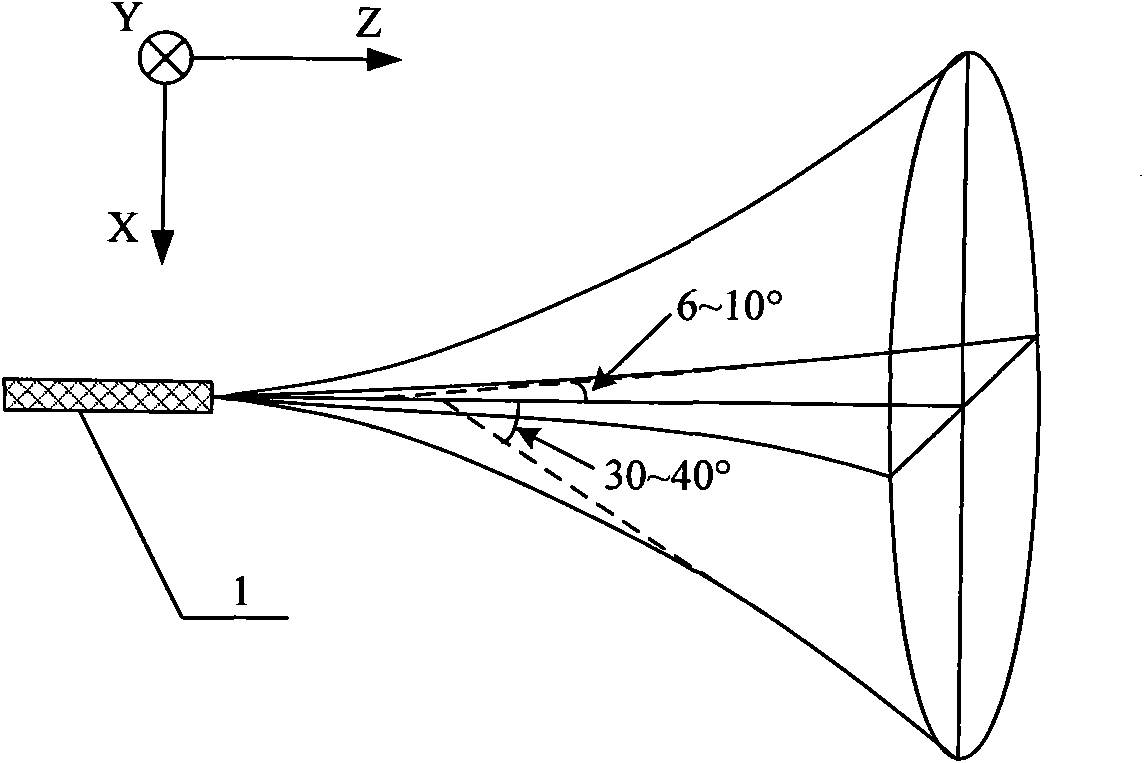

[0018] The size of the optical waveguide on the primary doped optical waveguide chip 8 in the Y direction matches the size of the optical fiber 4 . Along the Z direction, the optical waveguide on the primary doped optical waveguide chip 8 is composed of expansion section waveguides 9 and contraction section waveguides 10 connected in sequence. The width of the input end of the waveguide 9 in the expansion section (the size in the X direction) matches the size of the end surface emitting semiconductor laser 1; the slope of the contour line of the waveguide 9 in the expansion section is equal to the tangent of the divergence angle in the X direction after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com