Silicon on insulator (SOI) wafer double-mask etching-based vertical comb teeth driven torsional micro-mirror and manufacturing method thereof

A vertical comb-tooth drive, micro-torsion mirror technology, applied in the photoengraving process of the pattern surface, the process for producing decorative surface effects, the micro-structure technology, etc., can solve the problem of large process error, high cost and complex process steps and other problems to achieve the effect of avoiding adhesion between comb teeth and reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

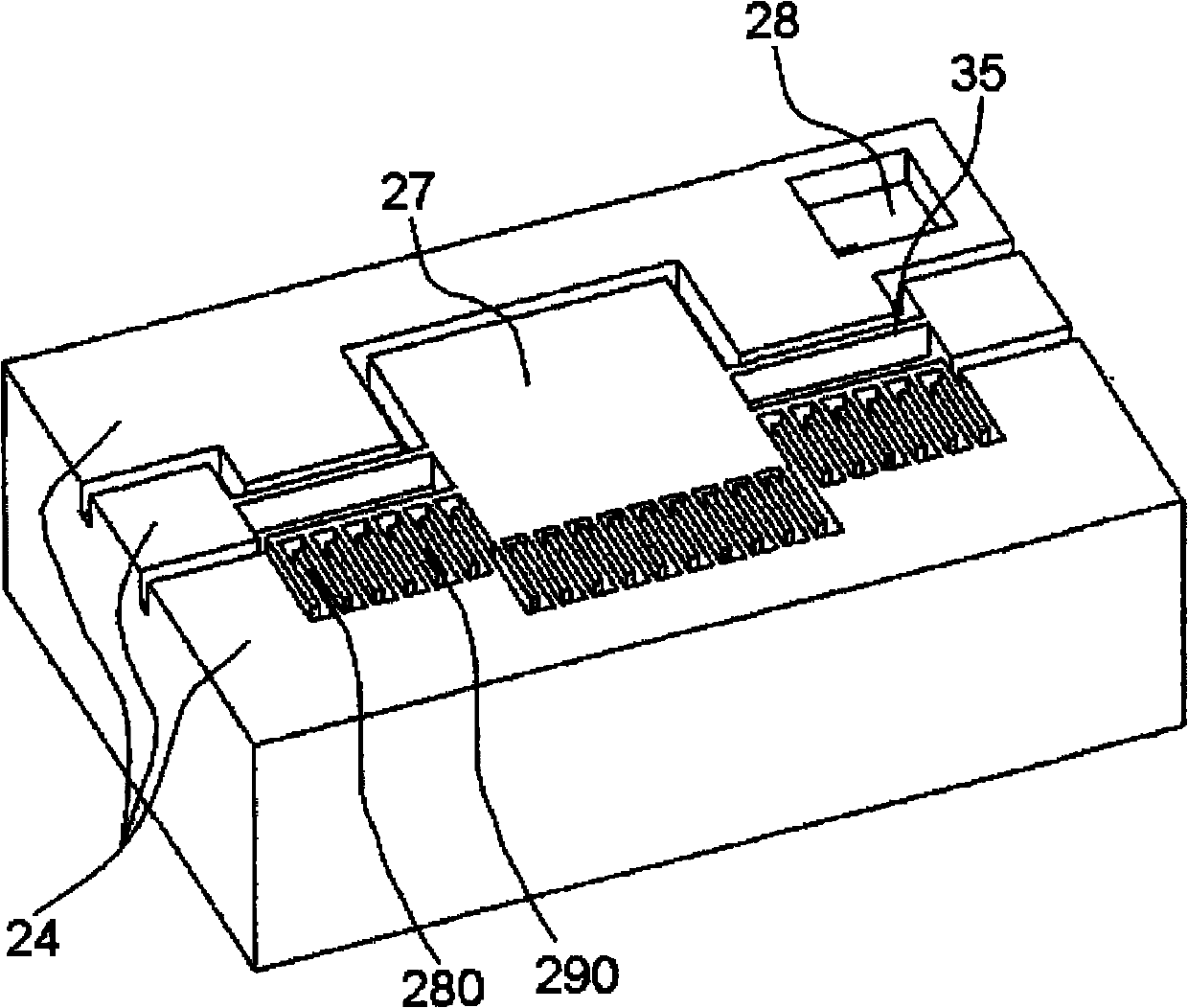

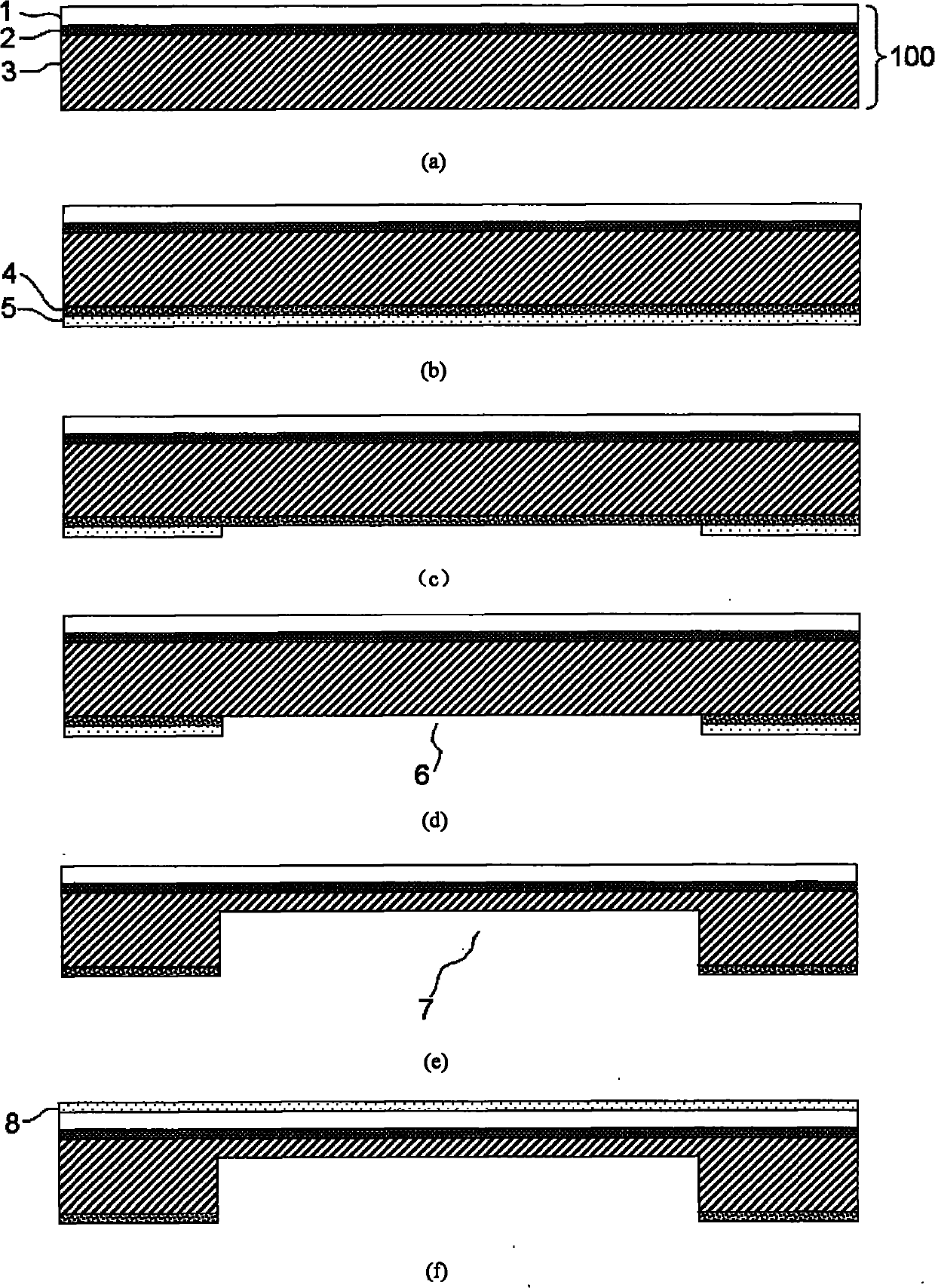

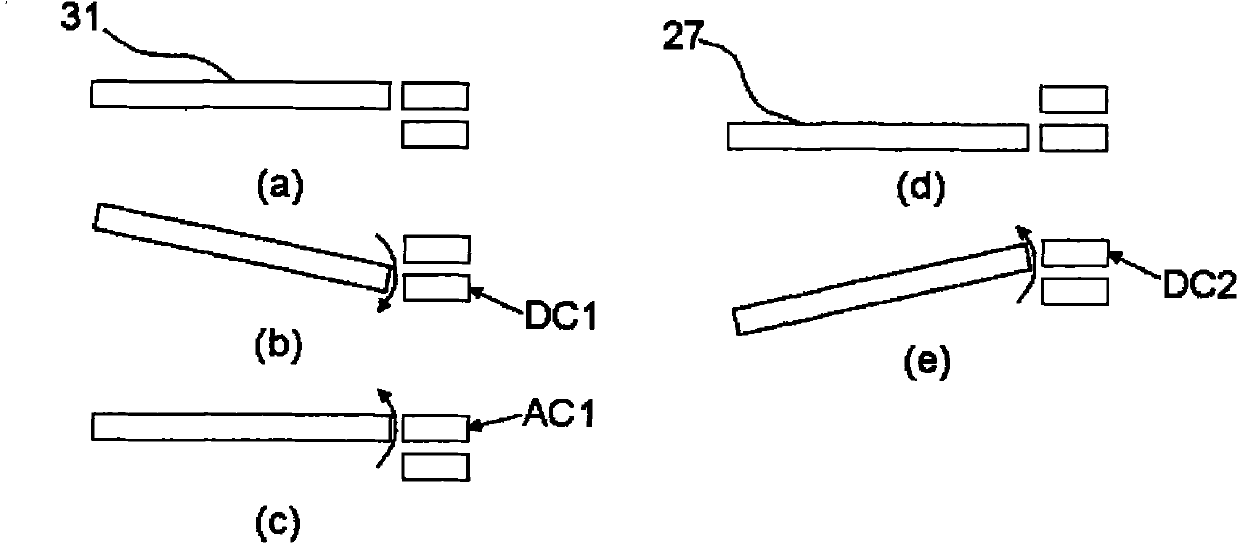

[0046] The vertical comb driven micro-torsion mirror based on SOI wafer double-mask etching in this embodiment sequentially includes a device layer 1, an insulating layer 2, and a base layer 3 with the same structure; the device layer 1 includes movable parts separated from each other and the fixed part, the movable part and the fixed part are separated by the device layer insulation groove 230, and the movable part is composed of the device layer mirror surface 31, the device layer torsion beam 220, the device layer anchor region 14 and the device layer movable comb teeth 210, The device layer mirror 31 is respectively connected to the device layer anchor regions 14 on both sides through the device layer torsion beams 220 at both ends. The movable comb 210; the fixed part is the part arranged separately and arranged around the movable part, including the device layer anchor point 29 without comb teeth, and a corresponding set of device layer fixed anchor points fixed on the de...

Embodiment 2

[0062] The vertical comb driven micro-torsion mirror based on SOI wafer double-mask etching in this embodiment sequentially includes a device layer 1, an insulating layer 2, and a base layer 3 with the same structure; the device layer 1 includes movable parts separated from each other and the fixed part, the movable part and the fixed part are separated by the device layer insulation groove 230, and the movable part is composed of the device layer mirror surface 31, the device layer torsion beam 220, the device layer anchor region 14 and the device layer movable comb teeth 210, The device layer mirror 31 is respectively connected to the device layer anchor regions 14 on both sides through the device layer torsion beams 220 at both ends. The movable comb 210; the fixed part is the part arranged separately and arranged around the movable part, including the device layer anchor point 29 without comb teeth, and a corresponding set of device layer fixed anchor points fixed on the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com