Multilayer heterogenic baffling ring high-speed centrifugal rectifying tower

A technology of high-speed centrifugation and baffles, applied in fractionation, separation methods, and separation of dispersed particles, can solve problems such as inconvenient determination of the number of theoretical plates, unfavorable distillation column size design, and poor fluid disturbance, and achieve operational Great flexibility, good design, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: rectification operation

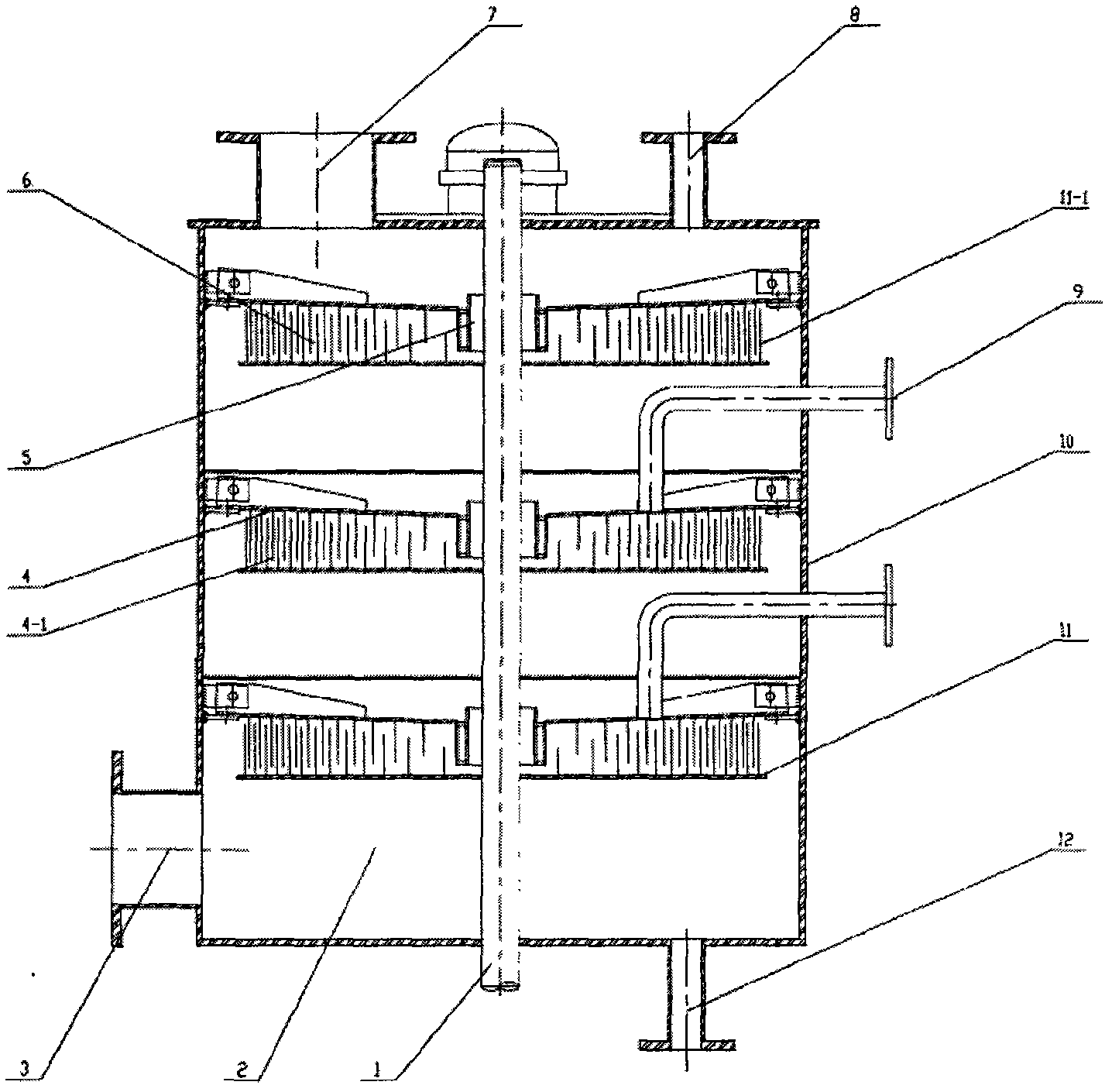

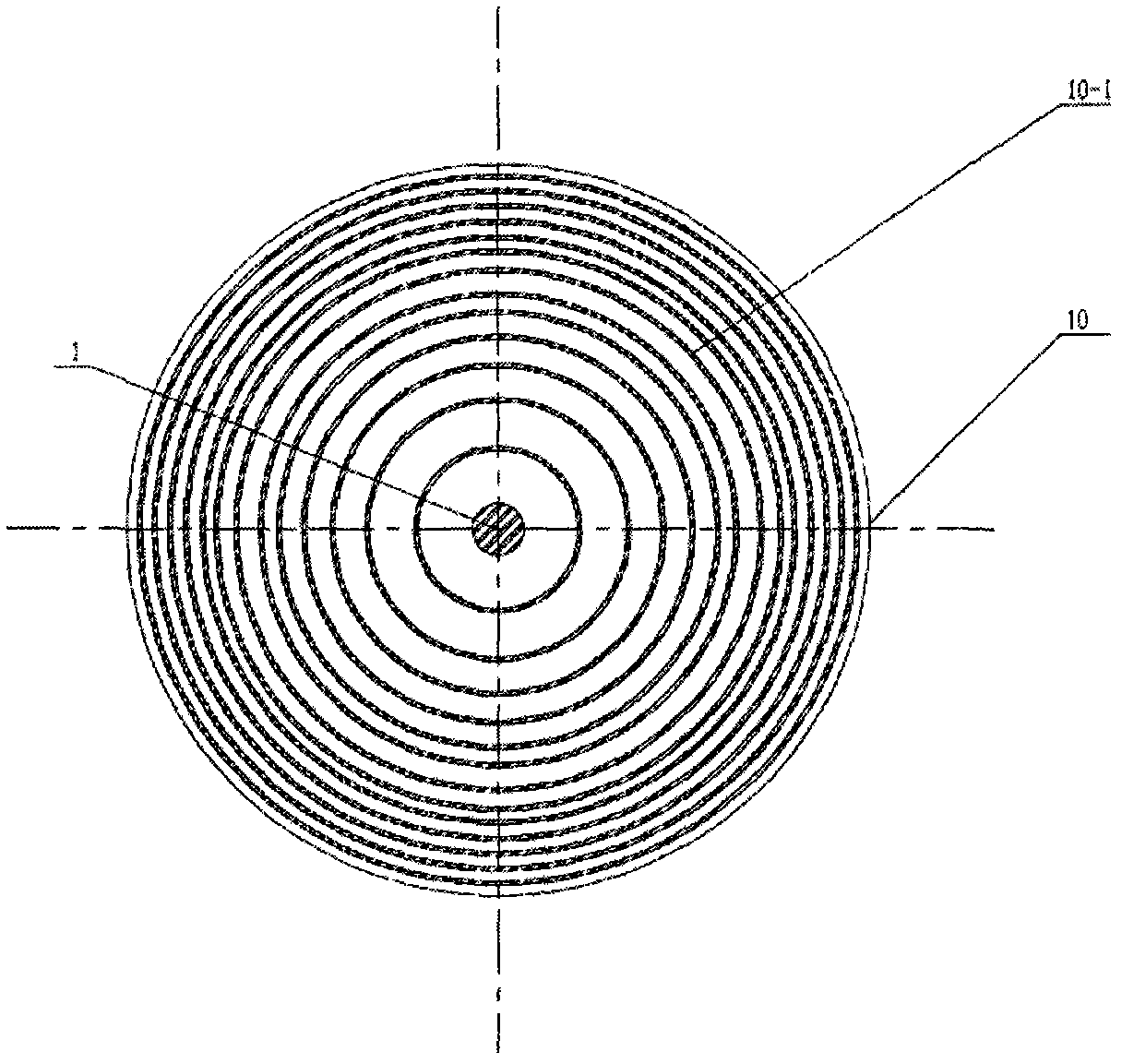

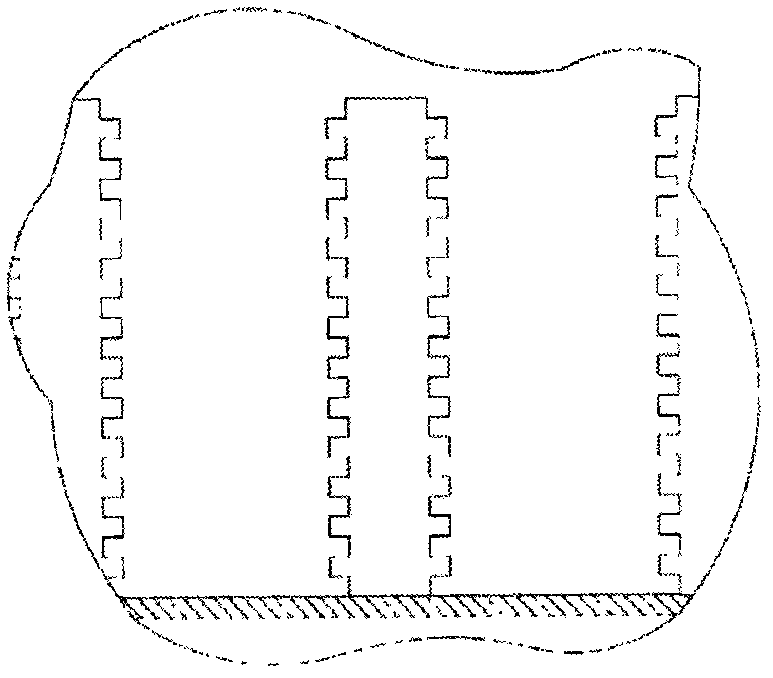

[0027] Such as figure 1 As shown, after starting the motor, the motor shaft (1) starts to rotate, the connected multi-layer brake disc (11) rotates accordingly, the multi-layer fixed disc (4) remains stationary, and a low pressure is generated in the liquid distribution chamber (5) At the same time, the adjacent brake disk baffles (11-1) and fixed disk baffles (4-1) form a zigzag flow channel. The feed liquid enters the passing liquid distribution chamber (5) of the shell from the liquid inlet (8) at the top of the shell. Due to the influence of high-speed centrifugal force, the feed liquid is thrown out in a zigzag shape between different baffle rings. During this process, the liquid is collided by the baffle ring and the special-shaped structure on it to form small droplets, and the whole flows in a high-speed turbulent flow; because the pressure in the central area (5) is small, the external reboiler enters the shell through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com