Process and complete equipment for producing porous ceramsite from construction waste

A technology for construction waste and complete sets of equipment, applied in the field of solid waste resource utilization, can solve problems such as land occupation, random stacking, and environmental hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

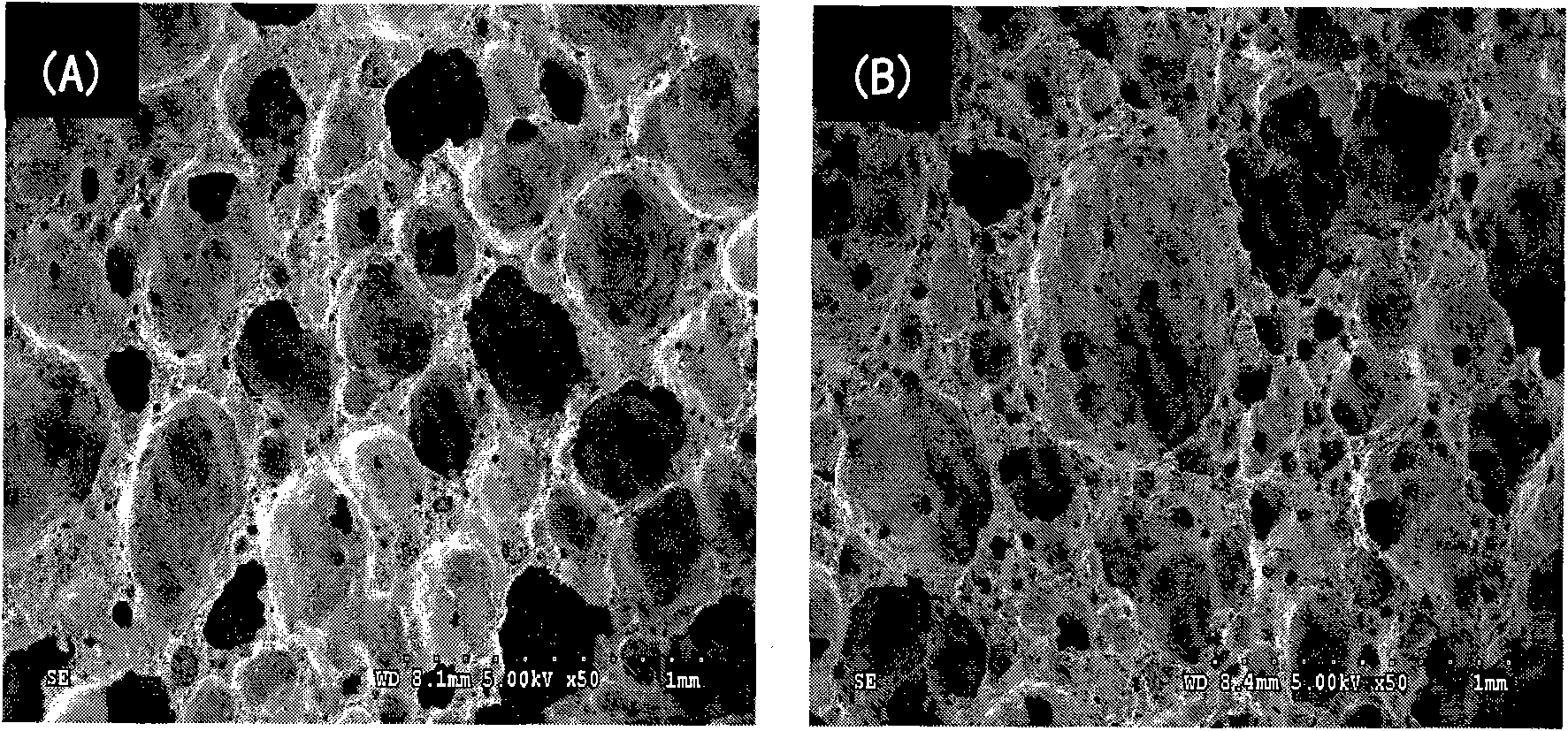

Image

Examples

Embodiment 1

[0013] A process for producing high-performance porous ceramsite from construction waste, specifically comprising the following steps:

[0014] (1) Pretreatment: Sorting steel bars, wood, plastics, aluminum alloys and other metals in construction waste and disposing of them as renewable resources, and then disposing of the remaining bricks, sandstones, decorative tiles, glass fragments, miscellaneous soil, etc. Crushing in the jaw crusher, sieve the broken material with 2mm, and return the oversized material to the crusher for further processing.

[0015] (2) Mixing and granulation process: transfer the undersize material to an externally heated rotary heating furnace for heat treatment at 450°C for 30 minutes, transfer the heat-treated raw materials to a ball mill, and perform ball milling for 45 minutes at a ball mill speed of 300 rpm / Minute. Add 20% pore-forming agent into the ball mill, and the pore-forming agent is produced by a patented waste straw preparation method. ...

Embodiment 2

[0019] A process for producing high-performance porous ceramsite from construction waste, specifically comprising the following steps:

[0020] (1) Pretreatment: Sorting steel bars, wood, plastics, aluminum alloys and other metals in construction waste and disposing of them as renewable resources, and then disposing of the remaining bricks, sandstones, decorative tiles, glass fragments, miscellaneous soil, etc. Crushing in the jaw crusher, sieve the broken material with 2mm, and return the oversized material to the crusher for further processing.

[0021] (2) Mixing and granulation process: Transfer the undersieve to an externally heated rotary heating furnace for heat treatment at 550°C for 60 minutes, transfer the heat-treated raw materials to a ball mill, and ball mill for 60 minutes at a speed of 400 rpm / Minute. Add 50% pore-forming agent into the ball mill, and the pore-forming agent is produced by a patented waste straw preparation method. Continue to dry mix in the b...

Embodiment 3

[0025] A process for producing high-performance porous ceramsite from construction waste, specifically comprising the following steps:

[0026] (1) Pretreatment: Sorting steel bars, wood, plastics, aluminum alloys and other metals in construction waste and disposing of them as renewable resources, and then disposing of the remaining bricks, sandstones, decorative tiles, glass fragments, miscellaneous soil, etc. Crushing in the jaw crusher, sieve the broken material with 2mm, and return the oversized material to the crusher for further processing.

[0027] (2) Mixing and granulation process: Transfer the under-sieve material to an externally heated rotary heating furnace for heat treatment at 500°C for 45 minutes, transfer the heat-treated raw materials to a ball mill, and ball mill for 50 minutes at a ball mill speed of 350 rpm / Minute. Add 40% pore-forming agent into the ball mill, and the pore-forming agent is produced by a patented waste straw preparation method. Continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com