Water cooling temperature control method of mass concrete of blast furnace foundation

A technology of mass concrete and temperature control method, which is applied in the direction of construction, building structure, and building material processing, etc., and can solve the problem of damage to the bearing capacity, use function and durability of engineering structures, accelerated natural aging of concrete, moisture and harmful substances Infiltration and other problems can be achieved to shorten the time of heat dissipation, ensure the quality of concrete, and reduce the effect of curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

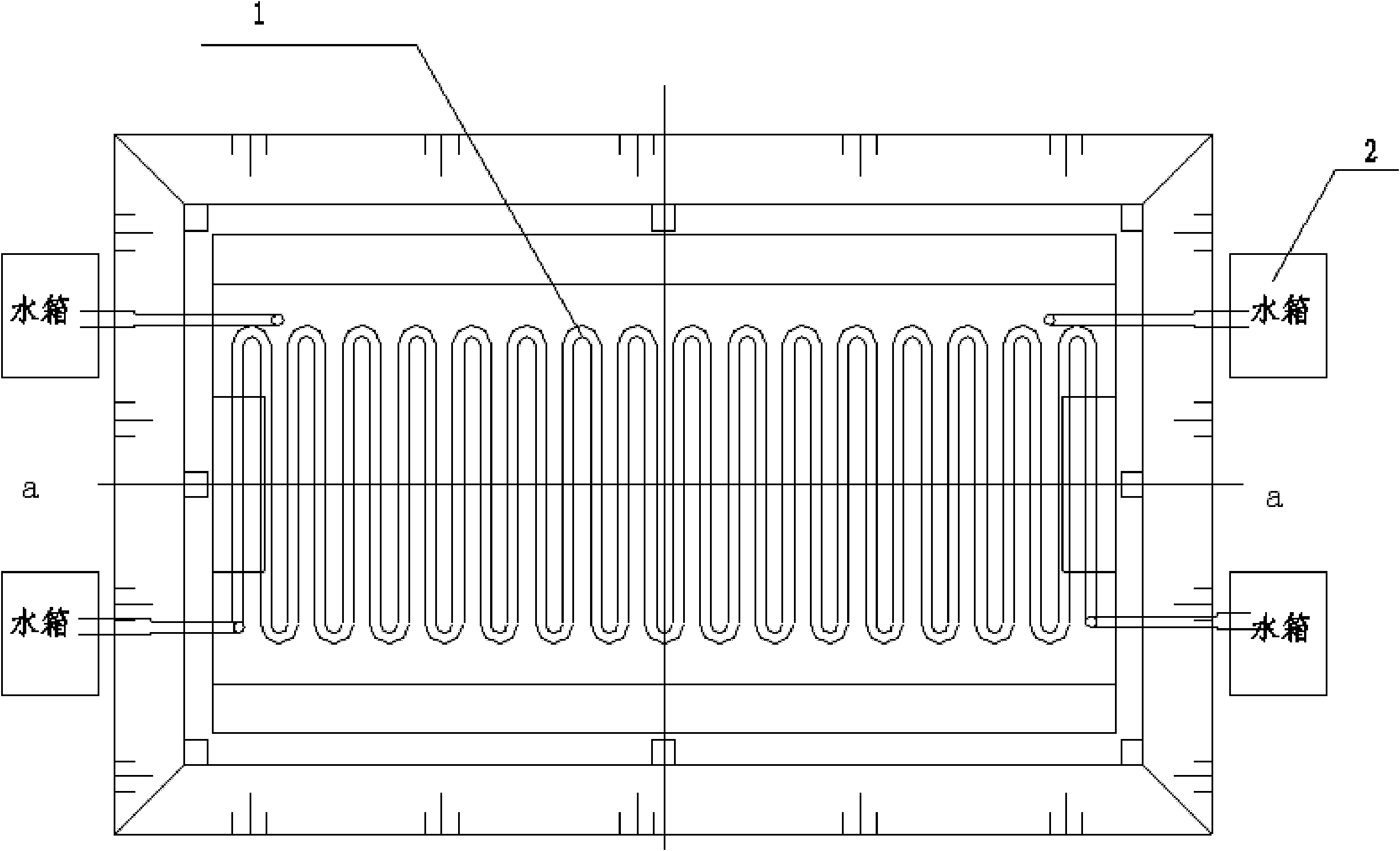

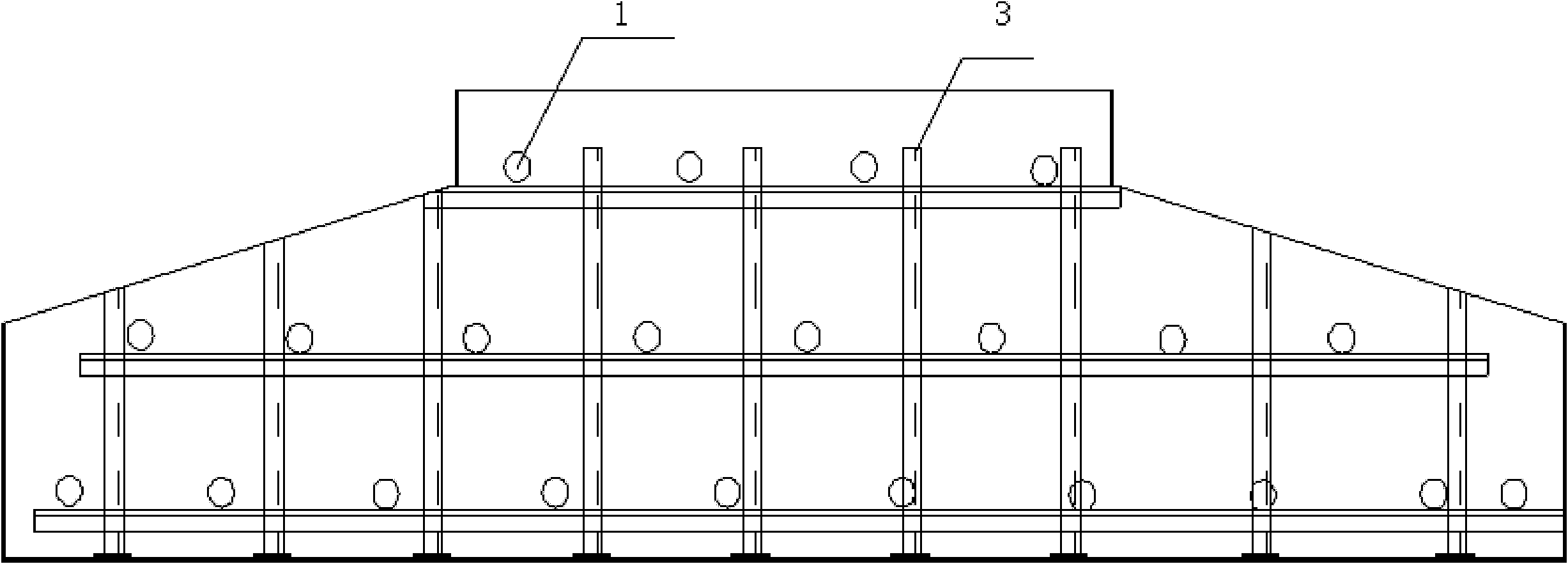

[0028] Embodiment 1: as figure 1 , 2 As shown, after the steel bars on the bottom plate of the blast furnace foundation are bound, the cooling water pipe 1 is constructed on the steel bar fixing frame 3. Within the scope of 53m×38.6m in the foundation, three layers of serpentine water pipes with a diameter of 48mm@1500mm are embedded in advance. The first The distance between the first layer and the concrete cushion is 1m, the distance between the second layer and the concrete cushion is 2.5m, and the distance between the third layer and the concrete cushion is 4m. Before pouring, it is necessary to conduct a water leak test and repair the water seepage point; (2) When the concrete is poured to the level of the cooling water pipe, the water will be passed immediately; The cooling water pipe starts to circulate; when the bottom of the second layer of cooling water pipe is poured with concrete, the water pump is turned on immediately, and the second layer of cooling water pipe ...

Embodiment 2

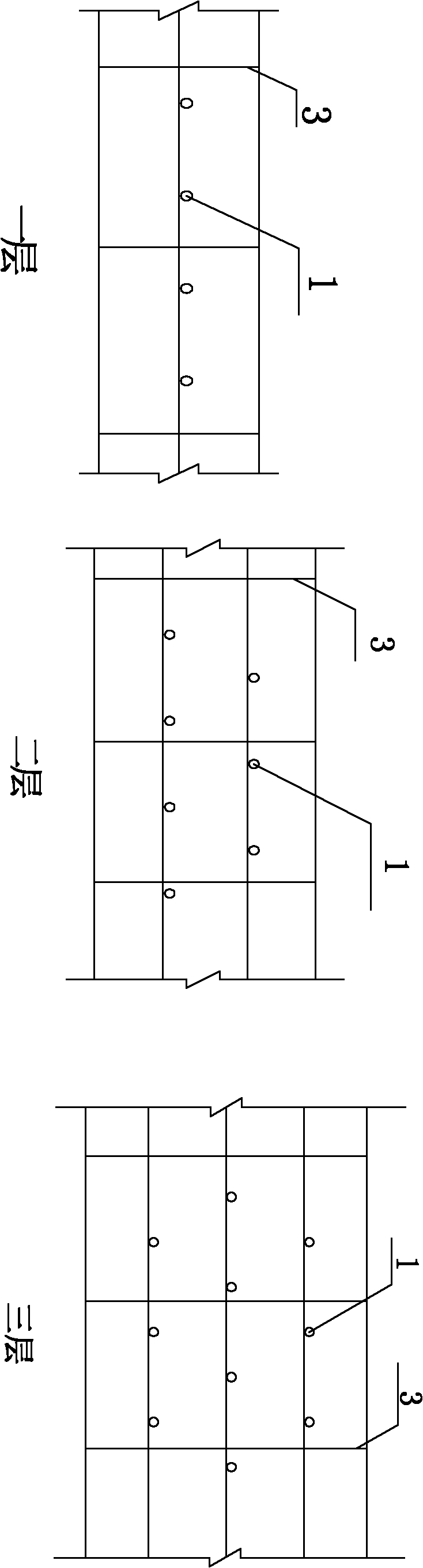

[0029] Embodiment 2: as Figure 4a As shown in, b, the hot rolling project of Nanshan Aluminum Alloy Processing Plant, the equipment foundation of the rough rolling mill area mainly includes the foundation of the rough rolling mill and vertical rolling mill. The whole foundation is located between the 8-12 / B-F line, and the foundation is excavated to -9.1m, 10.1m, the elevation of the top surface fluctuates more around ±0.000. The foundation is 36.625m long and 48.385m wide. Along the direction of Line 10, there is a 2.0m long post-cast belt running through the foundation, with a concrete volume of about 8600m 3 , The concrete strength grade is C30.S6. The dual control measures of external heat preservation and internal cooling are implemented for the foundation. For this reason, pre-buried in the foundation 6 (7) layers of serpentine water pipes @1500mm are horizontally arranged 500mm inside the foundation side, and the height direction is 1500mm inside the foundation sid...

Embodiment 3

[0030] Embodiment 3: as Figure 5a The foundation of the finishing mill of Nanshan Light Alloy Hot Rolling Project shown in b and b is located between the 30-34 / B-F line with a length of 50.0m and a width of 60.0m. The foundation is dug to -7.1m, -9.1m, -10.1m, -12.1m, and the elevation of the top surface fluctuates a lot. There is a 1.0m wide post-casting belt running through the foundation along the D-axis direction. The amount of concrete is about 7800m 3 , The concrete strength grade is C30.S6. The dual control measures of external heat preservation and internal cooling are implemented for the foundation. For this reason, pre-buried in the foundation 6 layers of @1500mm snake-shaped water pipes are arranged 500mm inside the foundation side, and each layer is a network frame composed of steel pipes with a vertical and horizontal spacing of 2000mm, and the layer height is 1500mm. To achieve the purpose of making the entire base temperature drop evenly. Each layer of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com