Polysilicon selective emitter solar cell manufacture process

A solar cell and manufacturing process technology, applied in sustainable manufacturing/processing, final product manufacturing, circuits, etc., can solve problems such as high cost, complicated process, and impact on material quality, and achieve high production efficiency, simple process, and energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

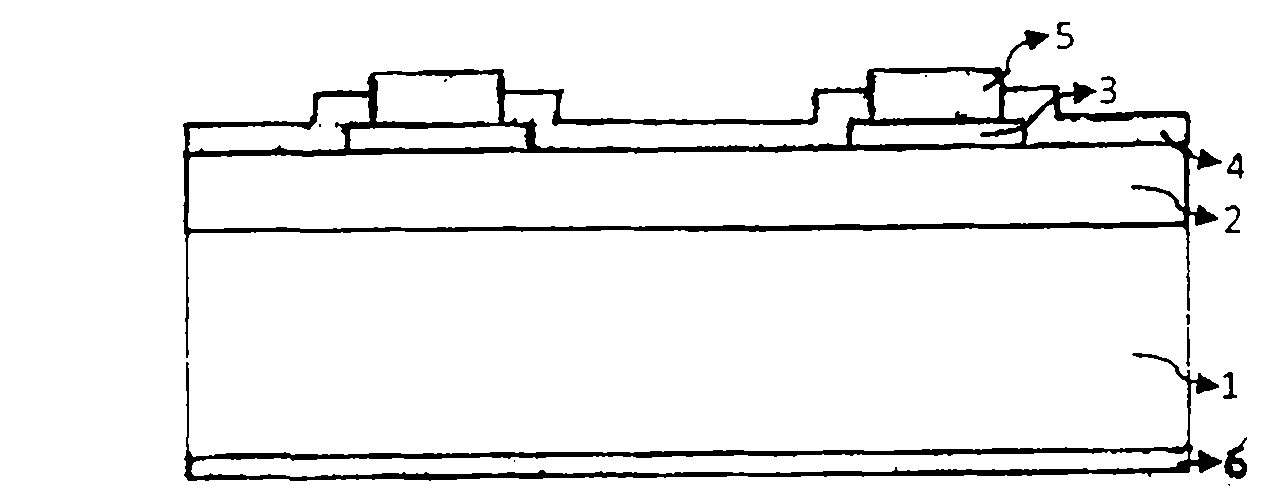

[0020] like figure 1 A polysilicon selective emitter solar cell using wet chemical etch-back is shown, including polysilicon wafer 1 and silicon wafer 1 diffused and junctioned to form a low-concentration phosphorus-doped region 2, and the front metallized electrode region 5 below The local high-concentration phosphorus doping region 3 .

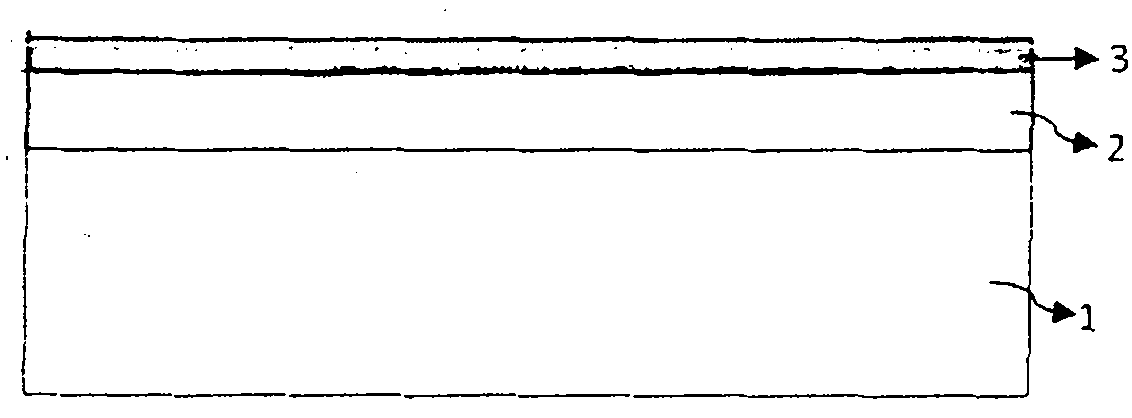

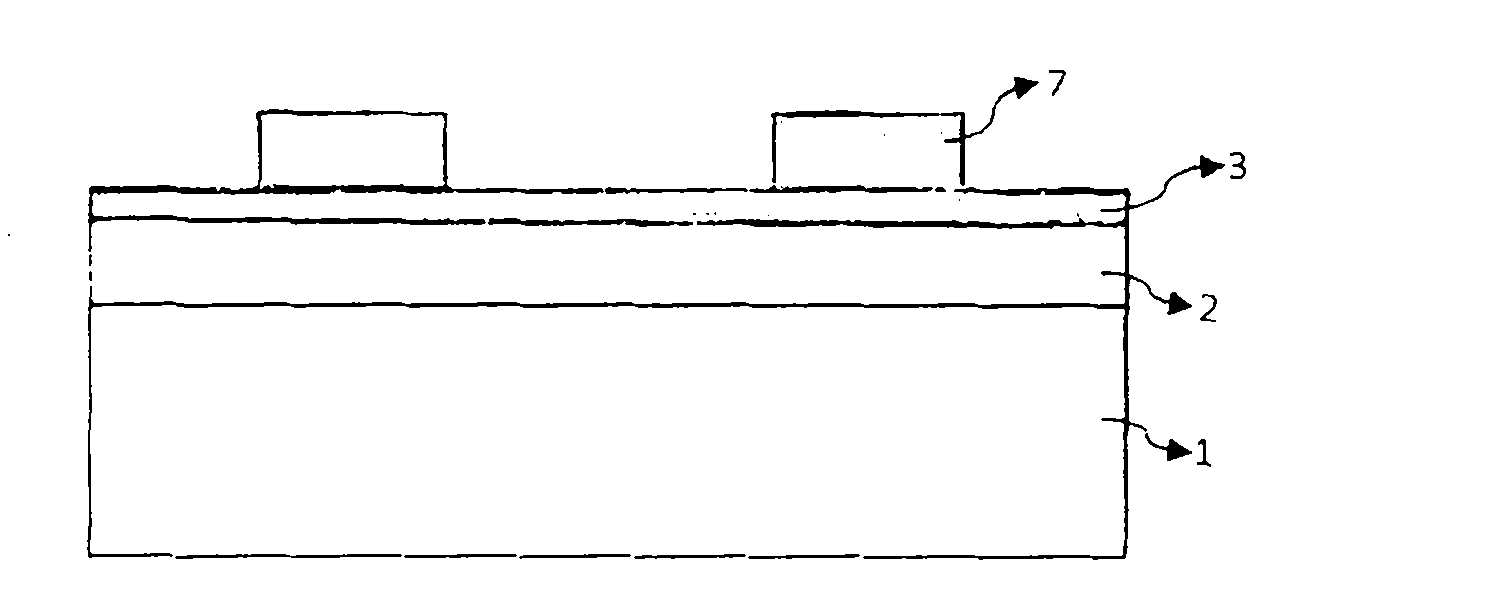

[0021] The schematic cross-sectional view of the solar cell continuous process steps adopting the process of the present invention is as follows Figure 2 to Figure 6 ;

[0022] The specific steps are as follows:

[0023] After the polycrystalline silicon wafer is dedamaged and textured (conventional method), it is diffused in a tubular diffusion furnace (conventional method), such as figure 2 As shown, the low-concentration phosphorus-doped region 2 and the high-concentration phosphorus-doped region 3 are completed in the same diffusion process. On the emitter, according to the front metallization pattern area 5, the etch-back barrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com