A perc superimposed se process with high opening pressure diffusion and high square resistance

A high square resistance and process technology, applied in the field of monocrystalline silicon solar cells, can solve the problems of low minority carrier lifetime, unreasonable PN junction structure, poor efficiency consistency between PERC+LDSE cells, etc., to achieve low surface phosphorus concentration, reduce Dead layer on the surface, the effect of improving the lifespan of minority carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

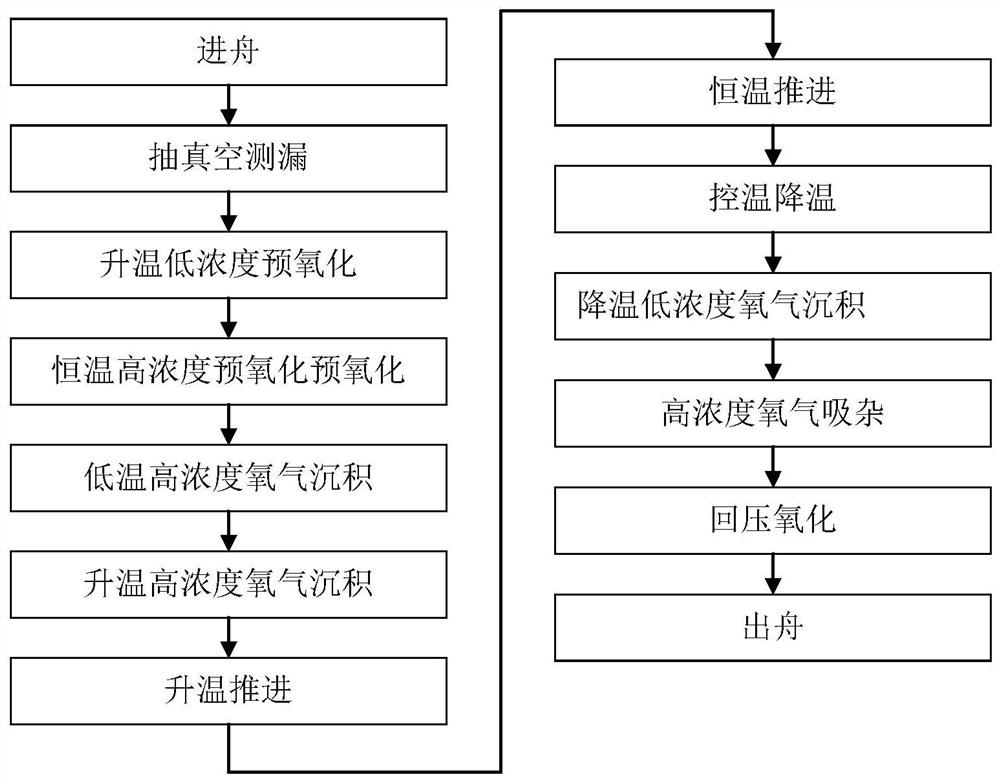

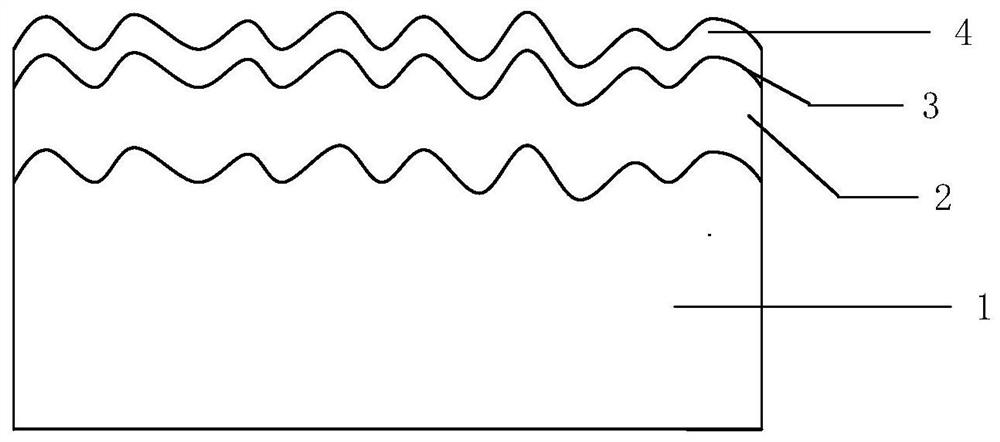

[0039] A PERC superimposed SE process with high opening pressure diffusion and high square resistance, such as figure 1 and figure 2 shown, including

[0040] Step S1: Entering the boat: After cleaning and texturing the P-type original silicon wafer 1, put it into the quartz boat and push it into the furnace tube of the diffusion furnace;

[0041] Step S2: Vacuum side leakage: Vacuumize the diffusion furnace to 100mbar, feed nitrogen at 7000sccm for 350s, exhaust the exhaust gas in the furnace tube, and raise the temperature of the diffusion furnace to 550°C;

[0042] Step S3: Heating up and low-concentration pre-oxidation: Raise the temperature of the diffusion furnace to 680°C, inject 500 sccm of oxygen and 1000 sccm of high nitrogen, and pre-oxidize the silicon wafer for 300 s to accelerate the discharge of exhaust gas in the furnace tube;

[0043] Step S4: Constant-temperature high-concentration pre-oxidation: The temperature of the diffusion furnace is raised and contr...

Embodiment 2

[0054] A PERC superimposed SE process with high opening pressure diffusion and high square resistance, such as figure 1 and figure 2 shown, including

[0055] Step S1: Entering the boat: After cleaning and texturing the P-type original silicon wafer 1, put it into the quartz boat and push it into the furnace tube of the diffusion furnace;

[0056] Step S2: Vacuumize side leakage: Vacuumize the diffusion furnace to 100mbar, feed nitrogen at 8000sccm for 400s, exhaust the exhaust gas in the furnace tube, and raise the temperature of the diffusion furnace to 600°C at the same time;

[0057] Step S3: Heating up and low-concentration pre-oxidation: Raise the temperature of the diffusion furnace to 720°C, inject 750 sccm of oxygen and 1500 sccm of nitrogen, and perform pre-oxidation on the silicon wafer for 350 s to accelerate the discharge of exhaust gas in the furnace tube;

[0058] Step S4: Constant-temperature high-concentration pre-oxidation: The temperature of the diffusion...

Embodiment 3

[0069] A PERC superimposed SE process with high opening pressure diffusion and high square resistance, such as figure 1 and figure 2 shown, including

[0070] Step S1: Entering the boat: After cleaning and texturing the P-type original silicon wafer 1, put it into the quartz boat and push it into the furnace tube of the diffusion furnace;

[0071] Step S2: Vacuum side leakage: Vacuumize the diffusion furnace to 100mbar, feed nitrogen at 10,000sccm for 450s, exhaust the exhaust gas in the furnace tube, and raise the temperature of the diffusion furnace to 700°C at the same time;

[0072] Step S3: Heating and low-concentration pre-oxidation: raise the temperature of the diffusion furnace to 780°C, inject 1000 sccm of oxygen and 2000 sccm of large nitrogen, and perform a low-concentration pre-oxidation on the silicon wafer for 400 seconds to accelerate the discharge of exhaust gas in the furnace tube;

[0073] Step S4: Pre-oxidation at constant temperature and high concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com