High-open-voltage diffusion high-sheet-resistance process of PERC superposition SE

A high square resistance and process technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problem of low minority carrier lifetime, poor efficiency consistency between PERC+LDSE cells, unreasonable PN junction structure, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

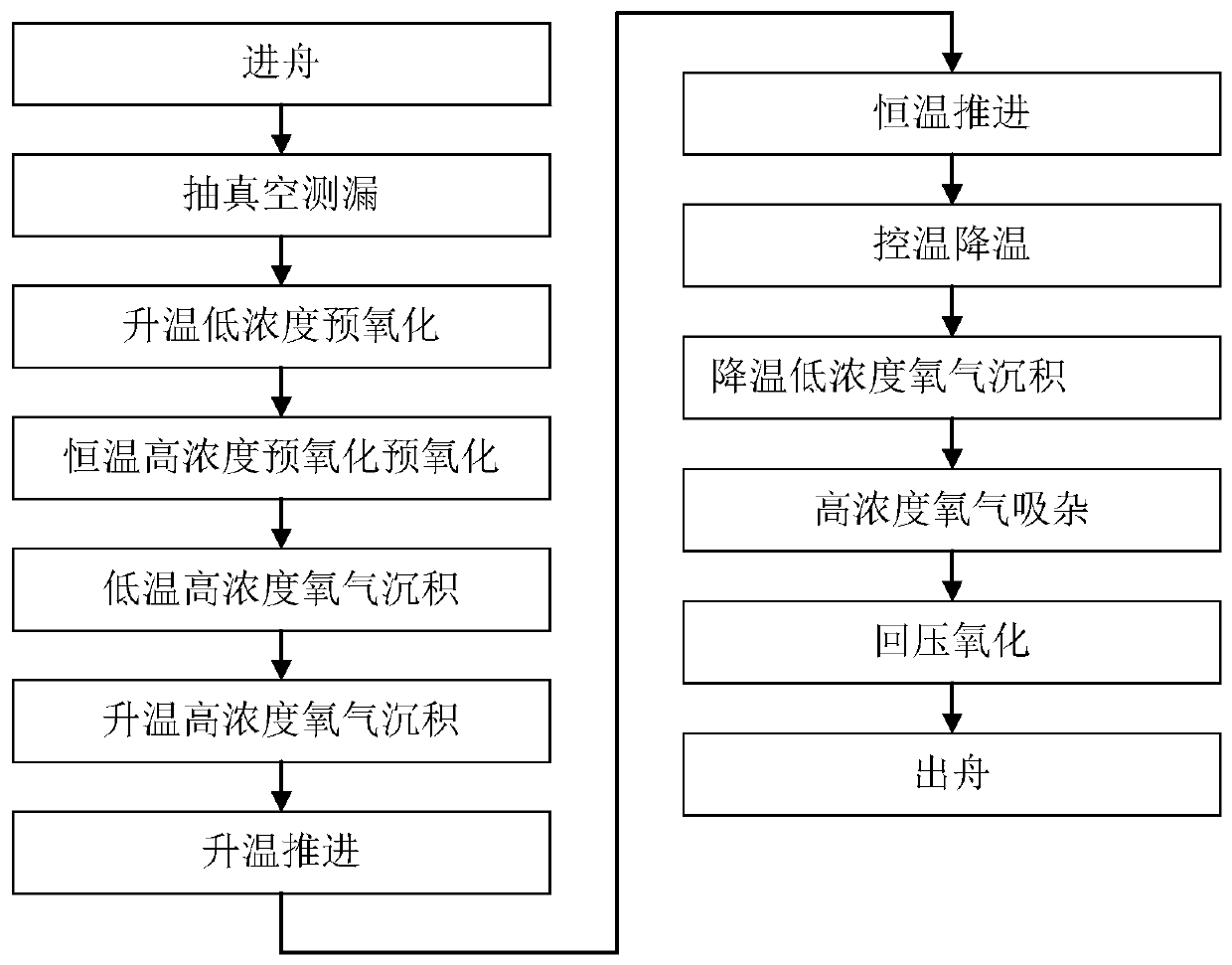

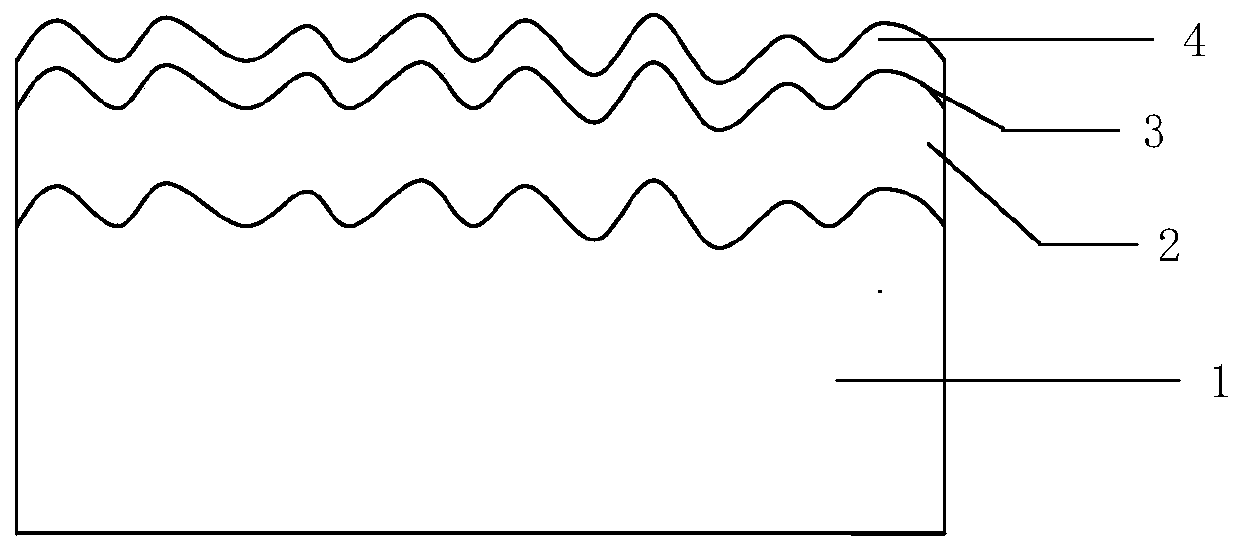

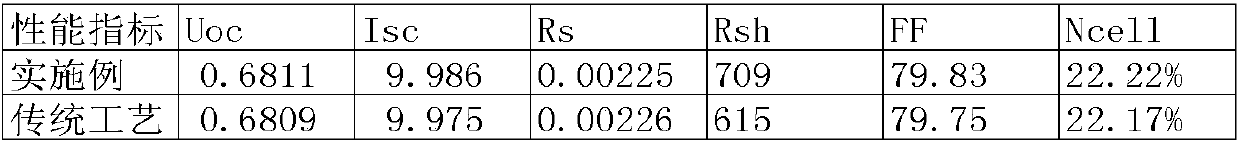

[0039] A PERC superimposed SE process with high opening pressure diffusion and high square resistance, such as figure 1 and figure 2 shown, including

[0040] Step S1: Entering the boat: After cleaning and texturing the P-type original silicon wafer 1, put it into the quartz boat and push it into the furnace tube of the diffusion furnace;

[0041] Step S2: Vacuum side leakage: Vacuumize the diffusion furnace to 100mbar, feed nitrogen at 7000sccm for 350s, exhaust the exhaust gas in the furnace tube, and raise the temperature of the diffusion furnace to 550°C;

[0042] Step S3: Heating up and low-concentration pre-oxidation: Raise the temperature of the diffusion furnace to 680°C, inject 500 sccm of oxygen and 1000 sccm of high nitrogen, and pre-oxidize the silicon wafer for 300 s to accelerate the discharge of exhaust gas in the furnace tube;

[0043] Step S4: Constant-temperature high-concentration pre-oxidation: The temperature of the diffusion furnace is raised and contr...

Embodiment 2

[0054] A PERC superimposed SE process with high opening pressure diffusion and high square resistance, such as figure 1 and figure 2 shown, including

[0055] Step S1: Entering the boat: After cleaning and texturing the P-type original silicon wafer 1, put it into the quartz boat and push it into the furnace tube of the diffusion furnace;

[0056] Step S2: Vacuumize side leakage: Vacuumize the diffusion furnace to 100mbar, feed nitrogen at 8000sccm for 400s, exhaust the exhaust gas in the furnace tube, and raise the temperature of the diffusion furnace to 600°C at the same time;

[0057] Step S3: Heating up and low-concentration pre-oxidation: Raise the temperature of the diffusion furnace to 720°C, inject 750 sccm of oxygen and 1500 sccm of nitrogen, and perform pre-oxidation on the silicon wafer for 350 s to accelerate the discharge of exhaust gas in the furnace tube;

[0058] Step S4: Constant-temperature high-concentration pre-oxidation: The temperature of the diffusion...

Embodiment 3

[0069] A PERC superimposed SE process with high opening pressure diffusion and high square resistance, such as figure 1 and figure 2 shown, including

[0070] Step S1: Entering the boat: After cleaning and texturing the P-type original silicon wafer 1, put it into the quartz boat and push it into the furnace tube of the diffusion furnace;

[0071] Step S2: Vacuum side leakage: Vacuumize the diffusion furnace to 100mbar, feed nitrogen at 10,000sccm for 450s, exhaust the exhaust gas in the furnace tube, and raise the temperature of the diffusion furnace to 700°C at the same time;

[0072] Step S3: Heating and low-concentration pre-oxidation: raise the temperature of the diffusion furnace to 780°C, inject 1000 sccm of oxygen and 2000 sccm of large nitrogen, and perform a low-concentration pre-oxidation on the silicon wafer for 400 seconds to accelerate the discharge of exhaust gas in the furnace tube;

[0073] Step S4: Pre-oxidation at constant temperature and high concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com