Cesium-beam tube based on glass structure

A cesium beam tube and glass technology, applied in the field of cesium beam tubes, can solve problems such as unreasonable structure, high production and manufacturing requirements of cesium beam tubes, and heavy overall quality, and achieve small internal space, reduce vacuum process requirements, and internal structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

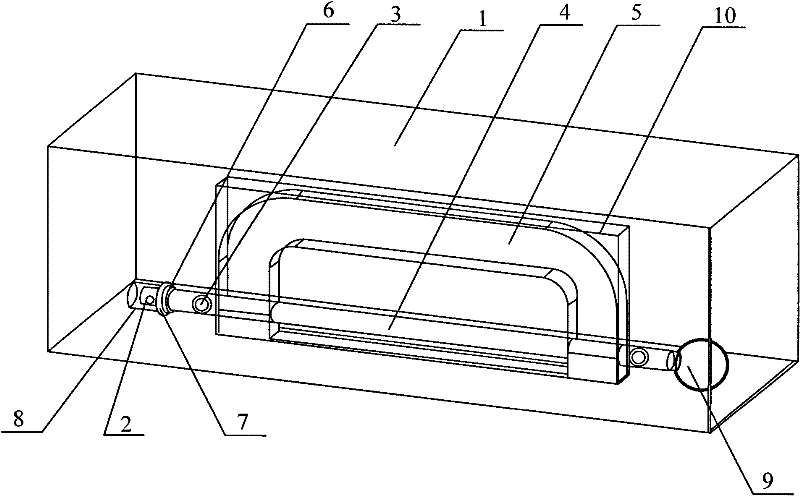

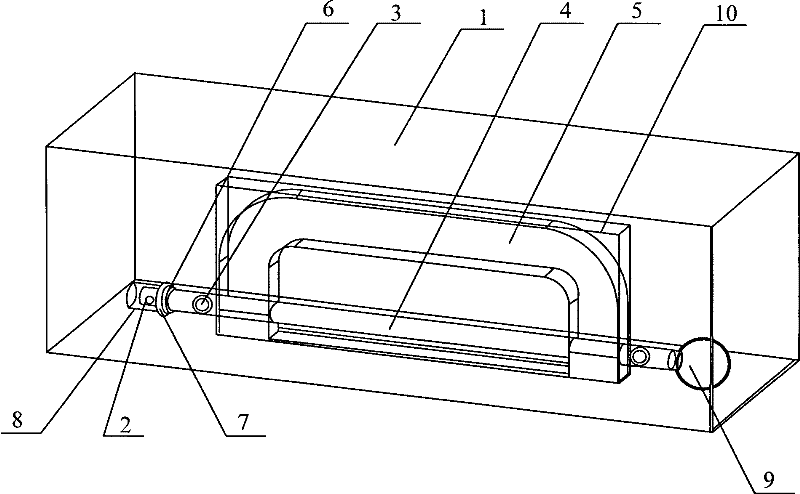

[0017] figure 1 As shown, the cesium beam tube of the present invention is arranged inside the casing 1, and the cesium beam tube is mainly composed of a cesium beam path tube 4, a transition section 6, a collimator 7, a cesium absorption bubble 9, a cesium furnace 8 and a cesium bubble 2 constitute. The cesium absorbing bubble 9 is sealedly connected to one end of the cesium beam path tube 4 , and the interior of the cesium absorbing bubble 9 is also communicated with the interior of the cesium beam path tube 4 . The transition section 6 is made of a metal material with an expansion coefficient close to that of glass. In order to ensure a high vacuum seal, the transition section 6 is hermetically connected to the other end of the cesium beam path tube 4. At the same time, it is made of corrosion-resistant materials. The completed collimator 7 is sealed with the transition section 6 by means of argon arc welding.

[0018] The cesium furnace 8 is directly matched and sealed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com