Oil-in-water emulsion with high content of oil phase and cleaning effect, preparation method thereof and application

An oil-in-water emulsion and emulsion technology, applied in skin care preparations, pharmaceutical formulas, cosmetic preparations, etc., can solve the problems of high packaging cost and weak decontamination ability of solvent-based products, and achieve significant re-emulsification ability and packaging The effect of low requirements, good flushing and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

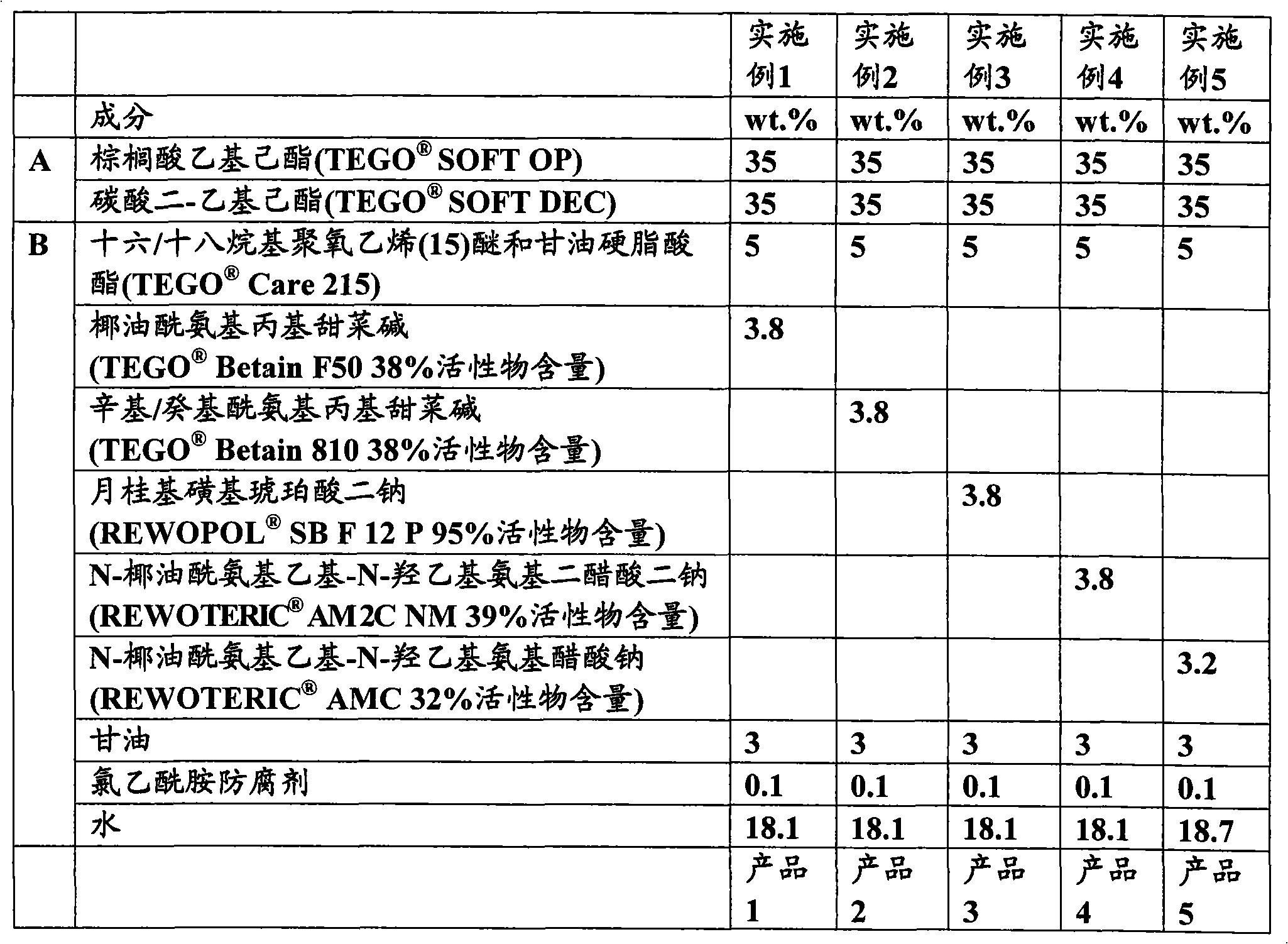

[0036] The formulations of Examples 1-5 are shown in Table 1 below.

[0037] Table 1

[0038]

[0039] The oil-in-water emulsions of Examples 1-5 were prepared according to the following steps:

[0040] 1). Dissolve glycerin and chloroacetamide preservatives in water to form a water phase, and then add an oil-in-water emulsifier (that is, cetearyl polyoxyethylene (15) ether and glyceryl stearate) and detergents (i.e., cocamidopropyl betaine, octyl / decylamidopropyl betaine, disodium lauryl sulfosuccinate, N-cocamidoethyl-N-hydroxyethyl Aminodiacetate disodium or N-cocoamidoethyl-N-hydroxyethylaminoacetate) were added to the entire water phase obtained by each formula, and heated to 80 ° C to dissolve to obtain a homogeneous water phase mixture, That is, phase B;

[0041] 2). Mix ethylhexyl palmitate and di-ethylhexyl carbonate to obtain the oil phase, that is, phase A, and then add phase A to phase B obtained in step 1) within 5 minutes under stirring at 800rpm (that is,...

Embodiment 6

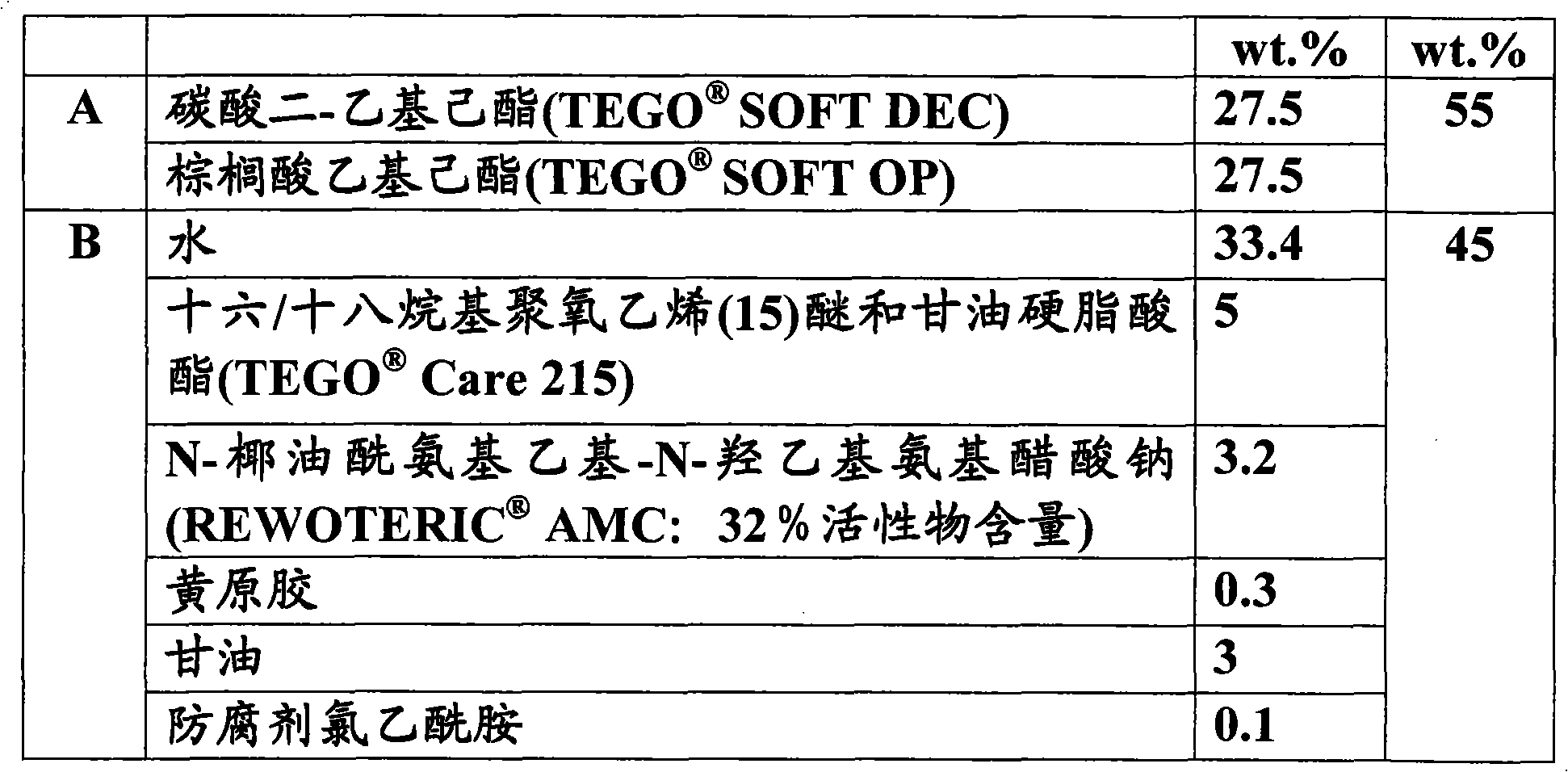

[0053] The formulation of Example 6 is shown in Table 2 below.

[0054] Table 2

[0055]

[0056] The oil-in-water emulsion of Example 6 was prepared according to the following steps:

[0057] 1). Dissolve glycerin, xanthan gum and chloroacetamide preservatives in water to form a water phase, then add the oil-in-water emulsifier and detergent into the resulting entire water phase, and heat to 80°C to dissolve to obtain a homogeneous The aqueous phase mixture of the phase, that is, the B phase;

[0058] 2). Mix ethylhexyl palmitate and di-ethylhexyl carbonate to obtain the oil phase, that is, phase A, and then add phase A to phase B obtained in step 1) within 3 minutes under stirring at 800rpm (that is, adding an oil phase accounting for 18wt.% of the total amount of the emulsion per minute), the entire system remains in a uniform emulsified state throughout the addition process; and

[0059] 3). After all the oil phase A is added, increase the stirring speed to 1000rpm f...

Embodiment 7

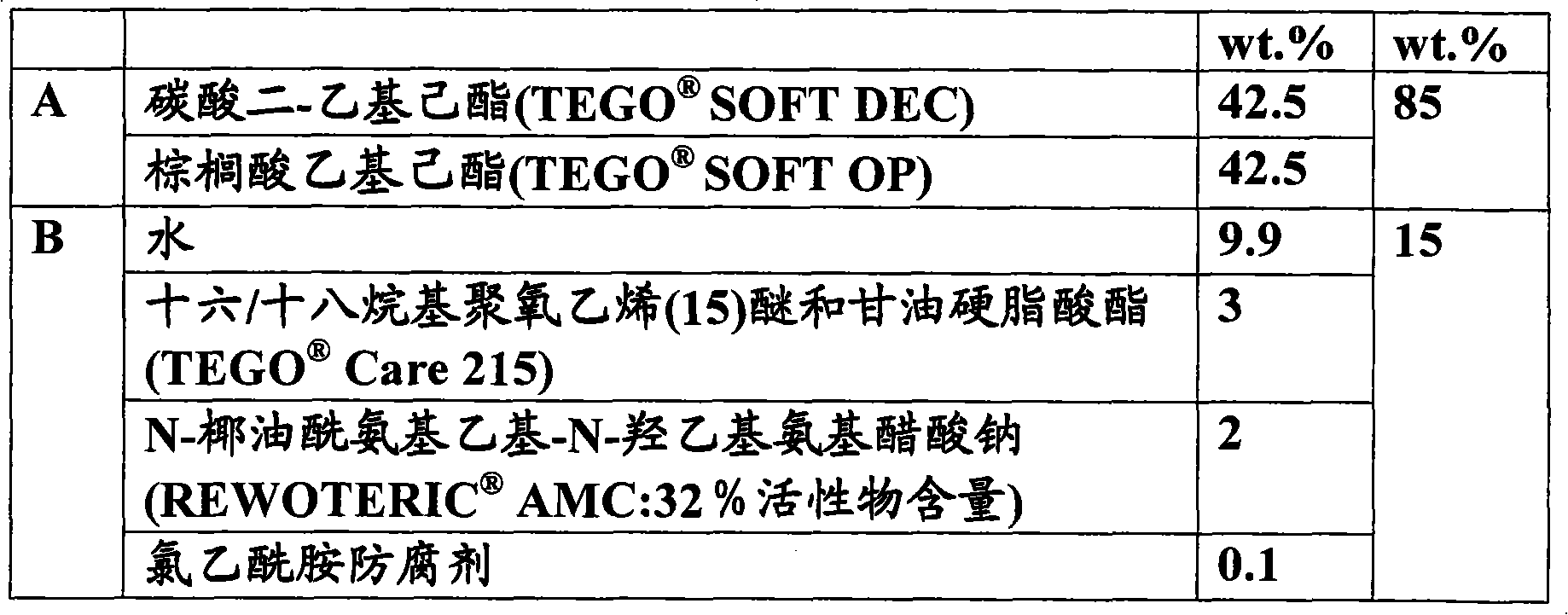

[0063] The formulation of Example 7 is shown in Table 3 below.

[0064] table 3

[0065]

[0066] The oil-in-water emulsion of Example 7 was prepared according to the following steps:

[0067] 1). Dissolve the chloroacetamide preservative in water to form a water phase, then add the oil-in-water emulsifier and detergent into the resulting entire water phase, and heat to 80°C to dissolve to obtain a homogeneous water phase mixture, That is, phase B;

[0068] 2). Mix ethylhexyl palmitate and di-ethylhexyl carbonate to obtain the oil phase, that is, phase A, and then add phase A to phase B obtained in step 1) within 15 minutes under stirring at 600 rpm (that is, add the oil phase that accounts for 5.7wt.% of the total amount of emulsion per minute), the whole system maintains a uniform emulsified state throughout the addition process; and

[0069] 3). After all the oil phase A is added, turn on the homogenizer for homogenization to obtain the oil-in-water emulsion product, na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com