Non-thermal plasma reactor

A non-thermal plasma and reactor technology, applied in deodorization, disinfection, etc., can solve the problem that the ability to decompose toxic organic matter is not as good as that of plasma reactors, so as to improve the efficiency of air disinfection and purification, high-efficiency killing rate, and long working life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

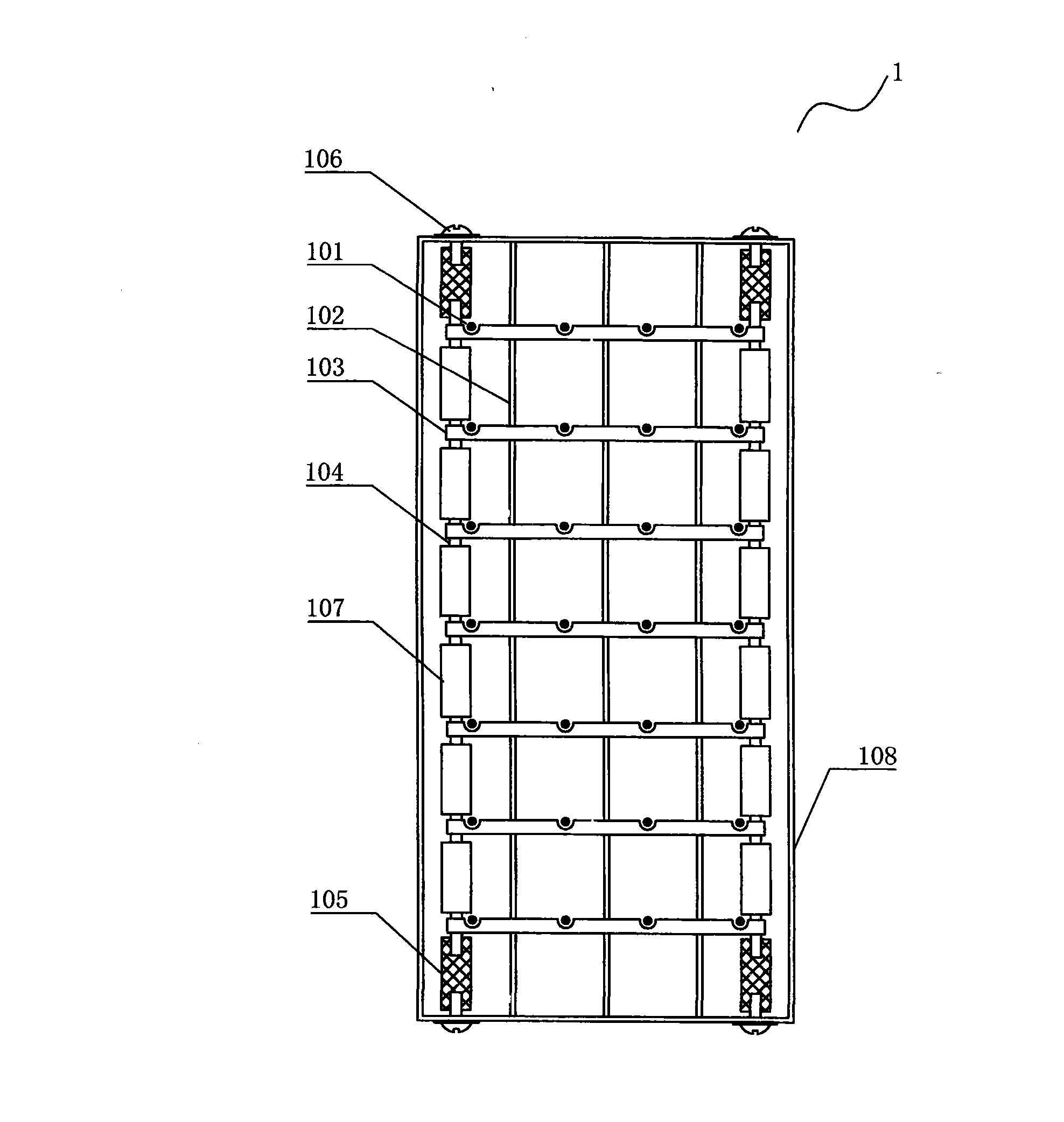

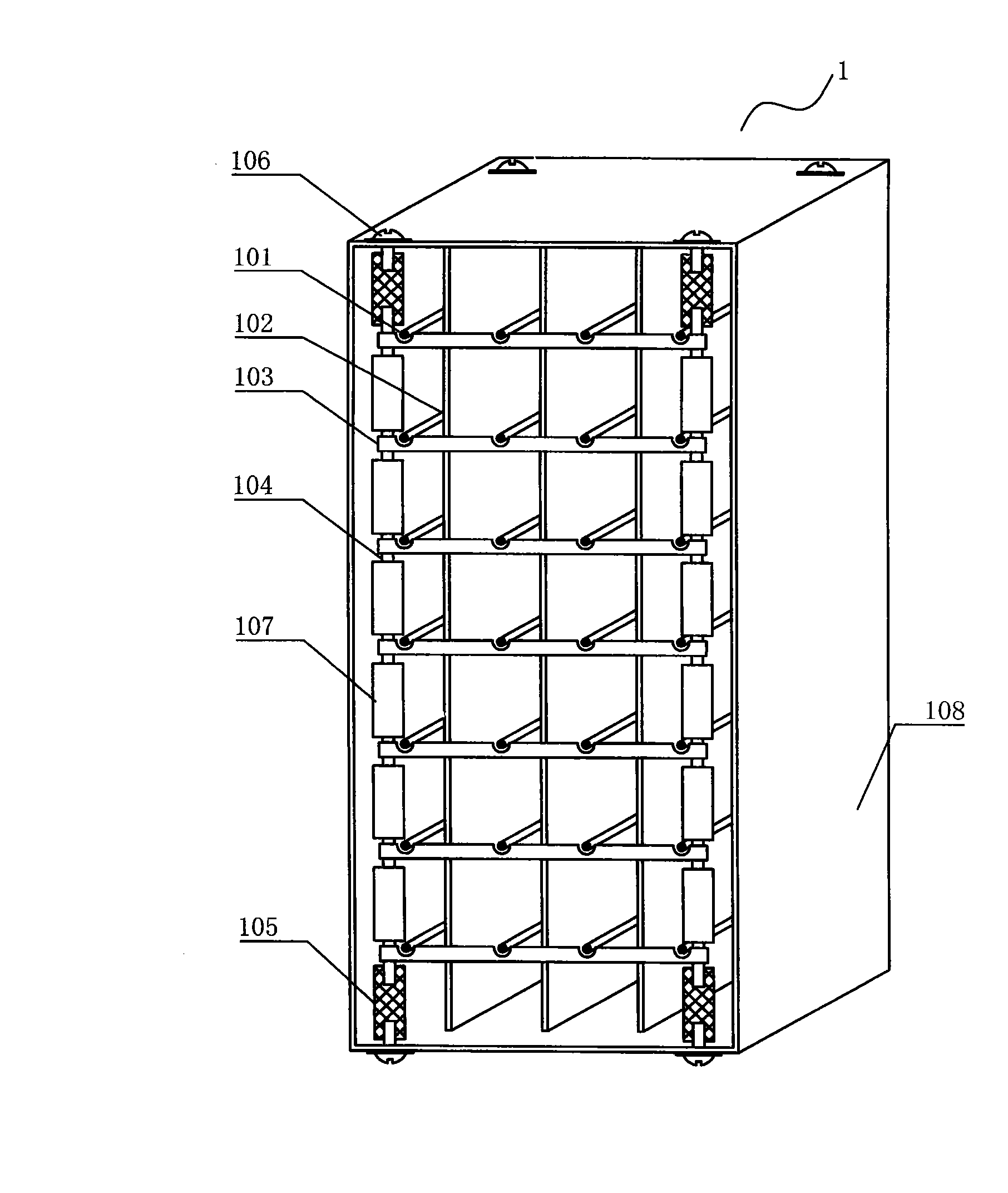

[0056] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, figure 2It is a perspective view of Embodiment 1 of the present invention. A non-thermal plasma reactor designed in the present invention includes a positive electrode 101, a negative electrode 102 and a shell 108, and the upper and lower sides of the negative electrode 102 are directly fixed in the metal shell 108. The front end of the housing 108 is provided with an air inlet 109 , the rear end of the housing 108 is provided with an air outlet 110 , and both the air inlet and the air outlet are provided with air filters. The positive electrode 101 is placed in the middle of two adjacent negative electrodes 102, and the positive electrode 101 and the negative electrode 102 are arranged in parallel according to the airflow direction. The positive electrode 101 is an assembly made of several nickel-chromium metal wires arranged in parallel at equal distances in the same plane, and ...

Embodiment 2

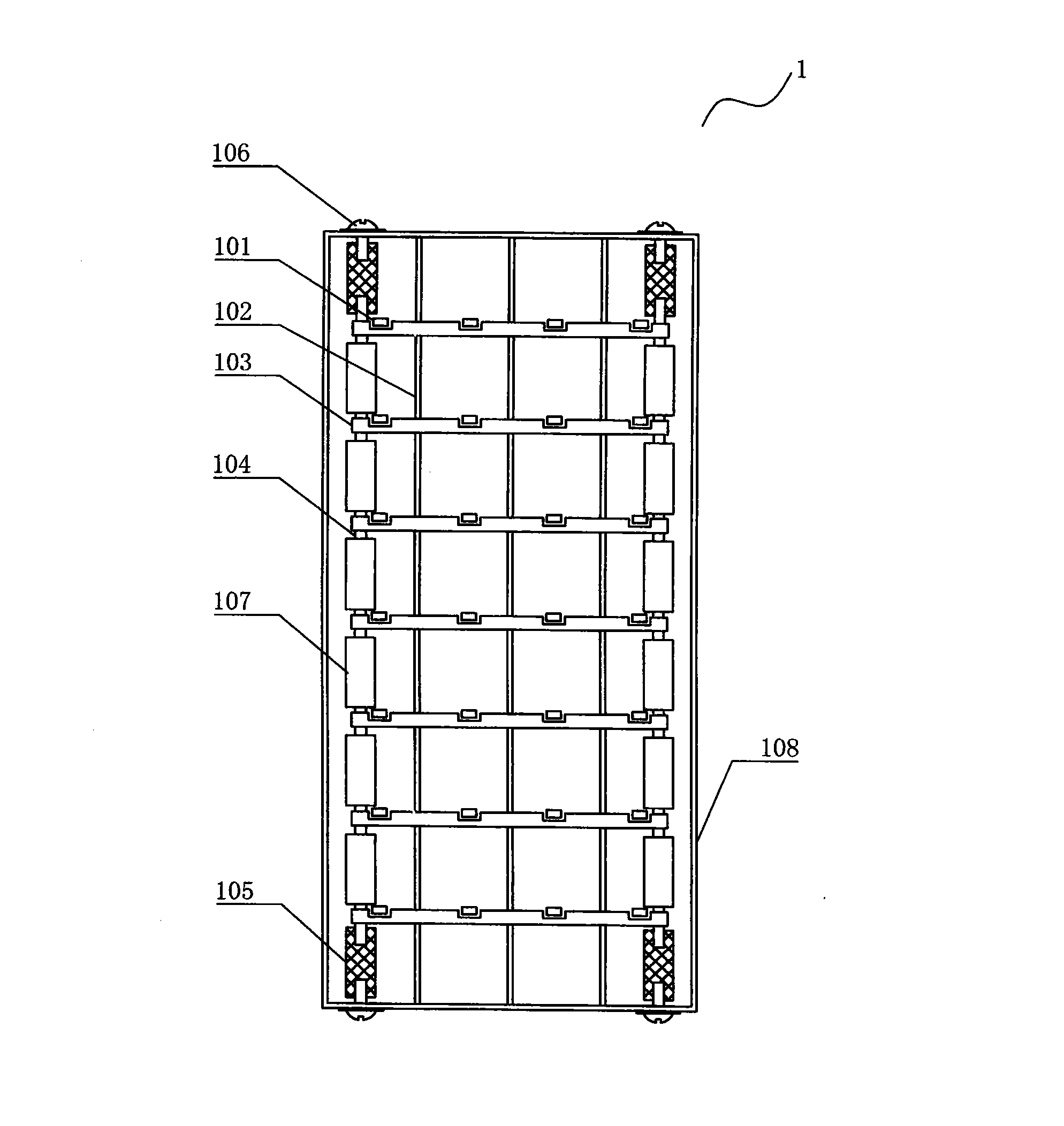

[0062] image 3 It is a structural schematic diagram of Embodiment 2 of the present invention, Figure 4 It is a perspective view of Embodiment 2 of the present invention.

[0063] A non-thermal plasma reactor designed in the present invention comprises a positive electrode 101, a negative electrode 102 and a casing 108, the upper and lower sides of the negative electrode 102 are directly fixed in the casing 108, and the front end of the casing 108 is provided with an air inlet 109, The rear end of the housing 108 is provided with an air outlet 110, and the positive electrode 101 is placed in the middle of two adjacent negative electrodes 102, and the positive electrode 101 and the negative electrode 102 are arranged in parallel according to the airflow direction. The positive electrode 101 is composed of several nickel-chromium metal strips arranged in parallel at equal distances in the same plane to form an assembly, a total of n groups; the negative electrode 102 is made o...

Embodiment 3

[0066] The anti-micro-discharge conductive rail 103 of the present invention is made of aluminum rods or stainless steel bars, and the two ends of the positive electrodes 101 made of several nickel-chromium wires or nickel-chromium metal strips are fixed on the anti-micro-discharge conductive rail 103 correspondingly. Position it in the groove of the position. The second embodiment is to prevent the micro-discharge conductive rail 103 from setting the positioning pin at the corresponding position, and the two ends of the positive electrode 101 are provided with fixing snares on the positioning pin, and are tightened and fixed. The third embodiment is to prevent the corresponding position on the micro-discharge conductive rail 103 from setting the positioning elastic metal sheet, and the two ends of the positive electrode 101 are provided with fixing snares on the top of the positioning elastic metal sheet, and are tightened and fixed. The height of the insulating connecting co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com