Pulse magneto liquid level vibration method for thinning metal solidification texture

A technology of metal solidification and pulse magnetism, which is applied in the field of material processing, can solve the problems of limited effective range of action, impact on production safety, splashing, etc., and achieve the effect of avoiding chilling effect or pollution, improving production efficiency, and simple disassembly and debugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

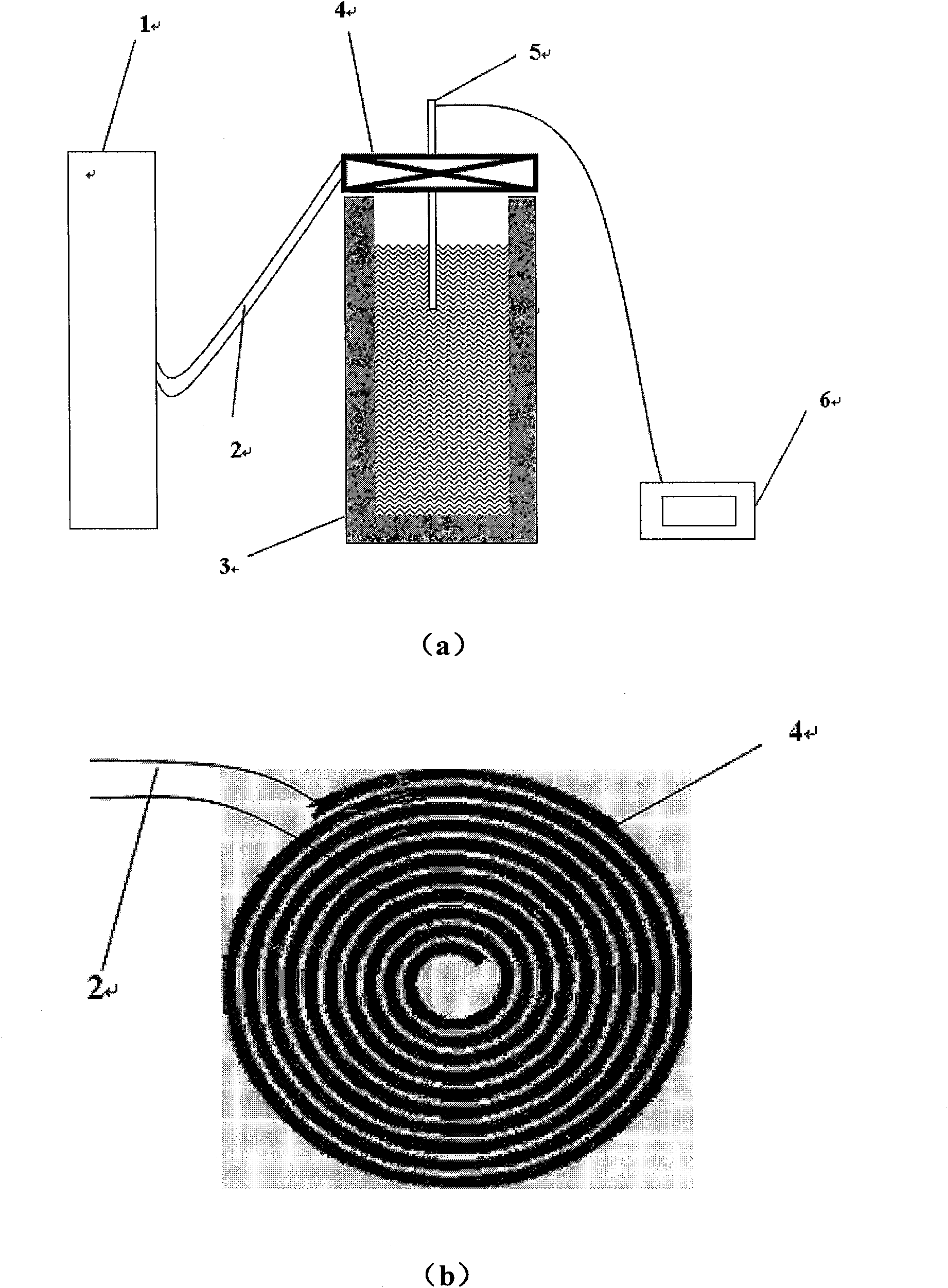

Method used

Image

Examples

Embodiment 1

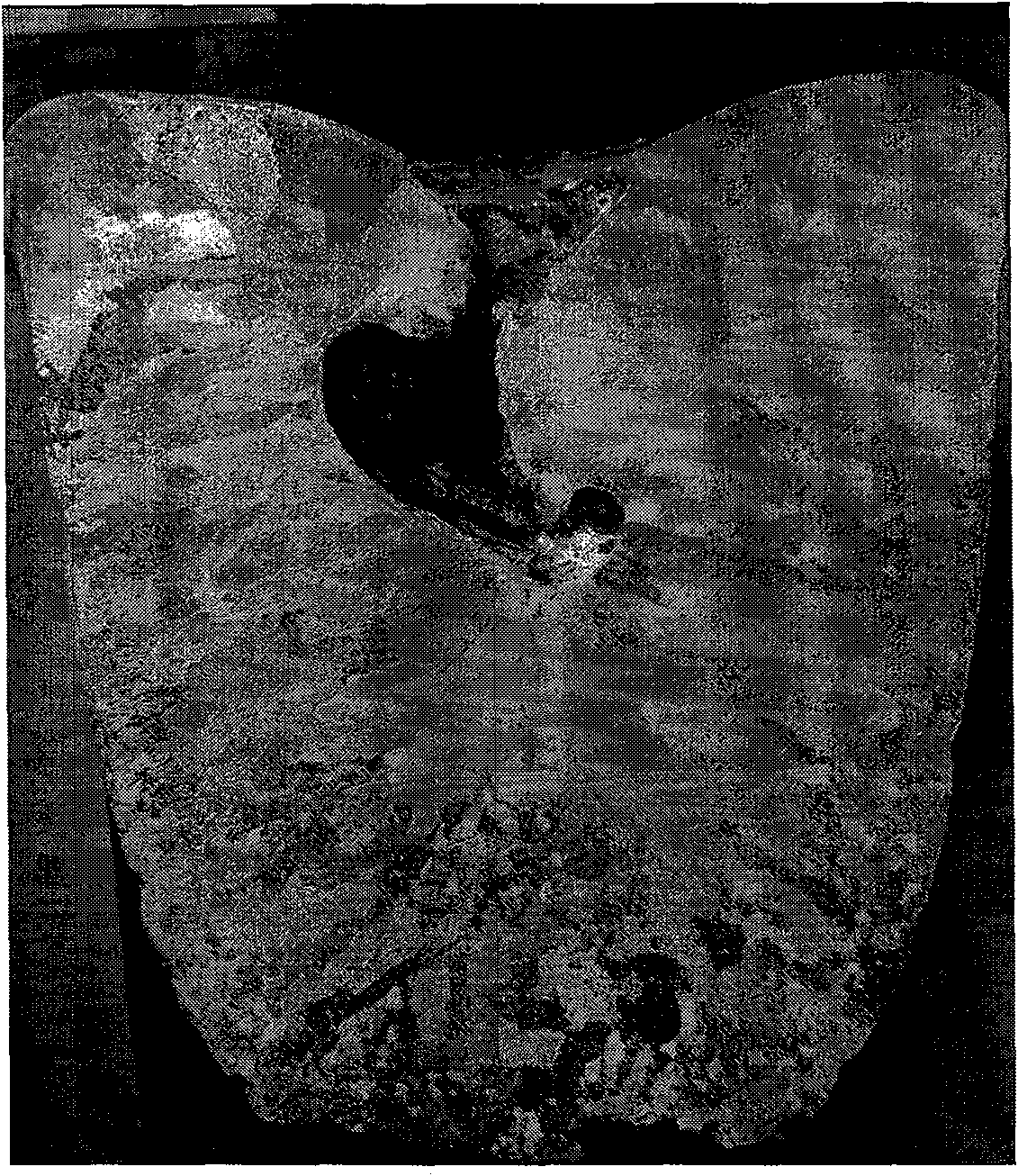

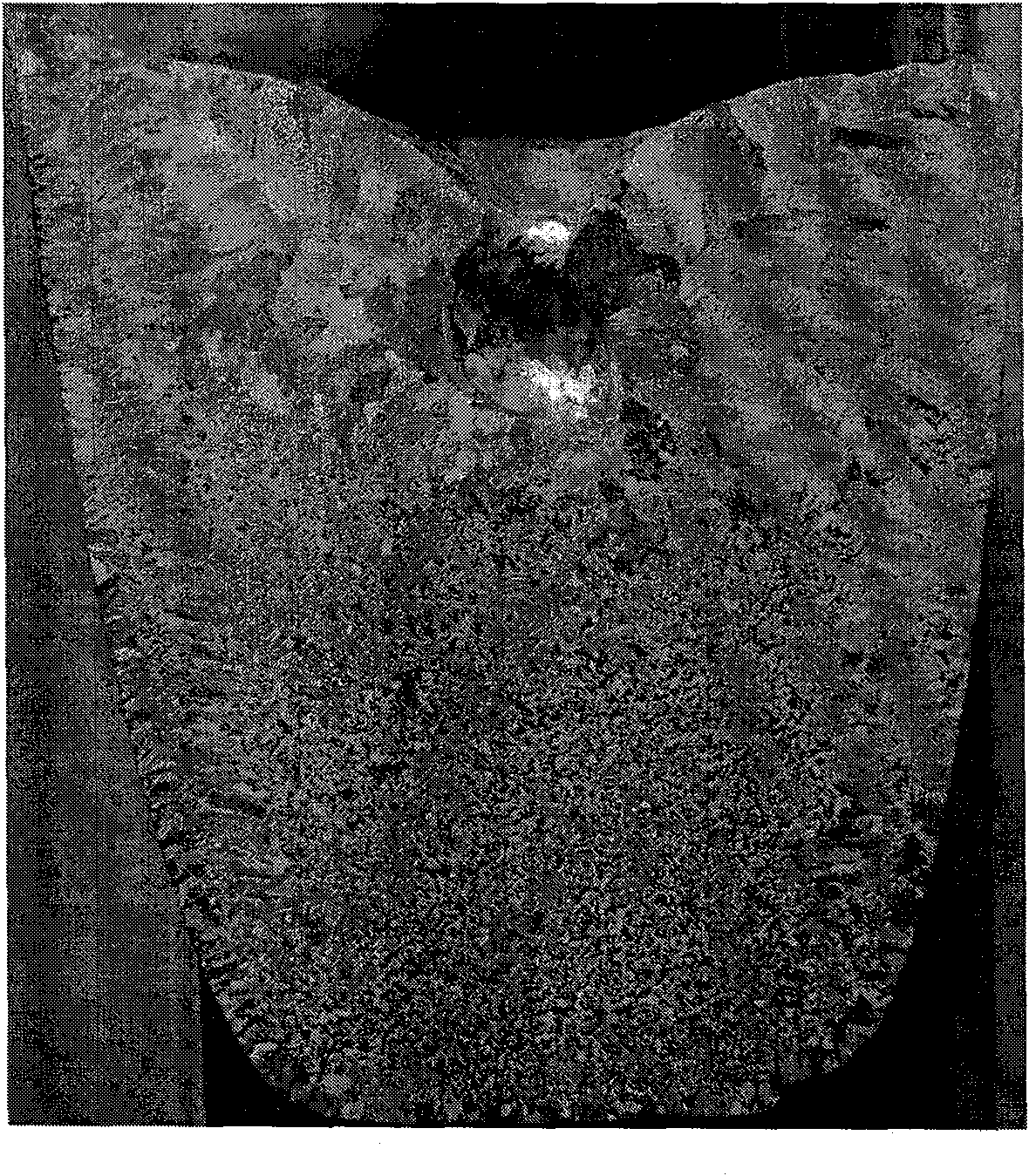

[0023] The material of this embodiment is industrial pure aluminum with a purity of 99.7wt%. The casting molds are water glass sand dry type and graphite type. The number of turns is 1 and the number of layers is 12. Pulsed magneto-induced liquid level oscillations are performed during the nucleation stage. To enhance contrast, figure 2 It is the macrostructure of pure aluminum that has not been treated with pulsed magnetic liquid surface oscillation when the casting mold is a sand mold. image 3 It is the macrostructure of pure aluminum subjected to pulsed magnetic liquid surface oscillation treatment in the nucleation stage when the casting mold is a sand mold (the peak value of the pulsed magnetic liquid surface oscillation current is 8h I A, processing frequency 6k I Hz, pulse width 50b I μs). Figure 4 It is the macrostructure of pure aluminum that has not been treated with pulsed magneto-induced liquid level oscillation when the casting mold is graphite type. Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com