Bolt special for internally and externally shielded cable material

A cable material and screw technology, applied in the field of screw structure, can solve problems such as poor sealing performance, slow down the speed of melting and conveying, uneven mixing, etc., to achieve the effect of ensuring product quality, increasing production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

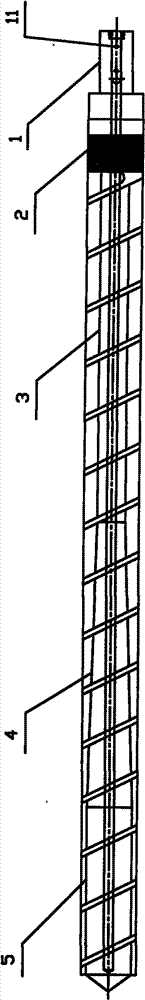

[0013] refer to figure 1 , the present invention is used for extrusion, and it is dedicated to conveying the inner and outer shielded cable materials; it includes a feeding section 3, a compression section 4 and a homogenizing section 5, and at the end of the feeding section 3, there is also a The threaded section 2 of the flow, the screw is connected with the barrel of the extruder through the threaded section 2, so that it is fixed in the barrel of the extruder. The end of the threaded section 2 is also provided with a connection end 1 connected to an external power device. In the extrusion device, the power device generally adopts a motor, and the main shaft of the motor is fixed to the screw rod through the mounting hole 11 made by the connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com