Beam-type limekiln

A lime kiln and beam type technology is applied in the improvement field of beam type lime kiln, which can solve the problems of weakening the calcination strength of the calcination zone, affecting the quality of calcined products, and impermeability of the limestone material, so as to achieve long-term safe operation extension and heat utilization. The best, the effect of increasing the calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

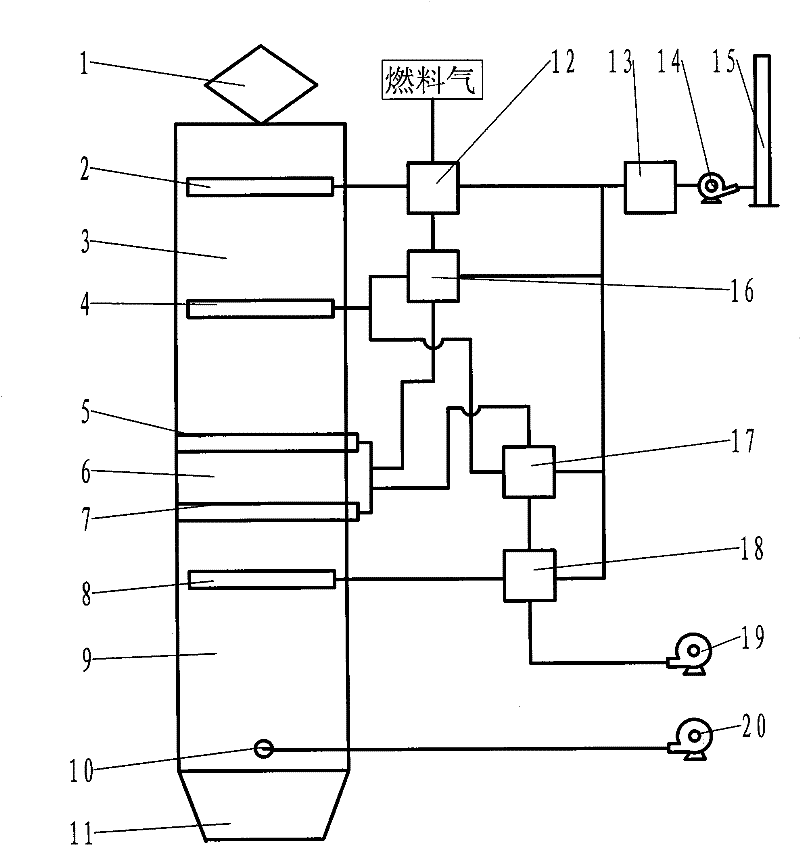

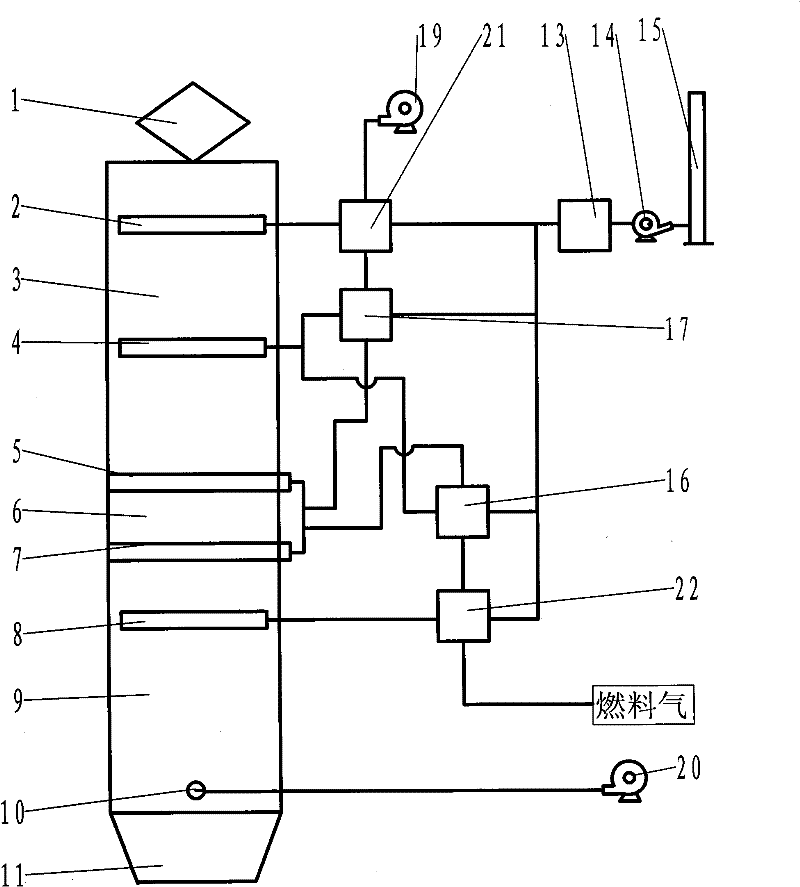

[0022] The beam type lime kiln of the present invention such as figure 1 As shown, it mainly includes kiln body, feeding system, combustion system, discharging system, air supply system and control system. The kiln body includes a preheating zone 3 , a calcining zone 6 , a cooling zone 9 and a discharge port 11 . The calcining zone is equipped with three upper combustion beams 5 and two lower combustion beams 7, two upper suction beams 2 are arranged on the upper part of the preheating zone, and two lower suction beams 8 are arranged on the middle part of the cooling zone. The middle part of the pre-tropical zone is provided with 2 high-temperature suction beams 4, such as Figure 5 , Figure 6 As shown, the high-temperature suction beam is a rectangular box-shaped body structure, and there are 10 suction holes 23 in the lower part of the box-shaped body, and the suction holes are elliptical. Both ends of the high-temperature suction beam are provided with connecting ports ...

Embodiment 2

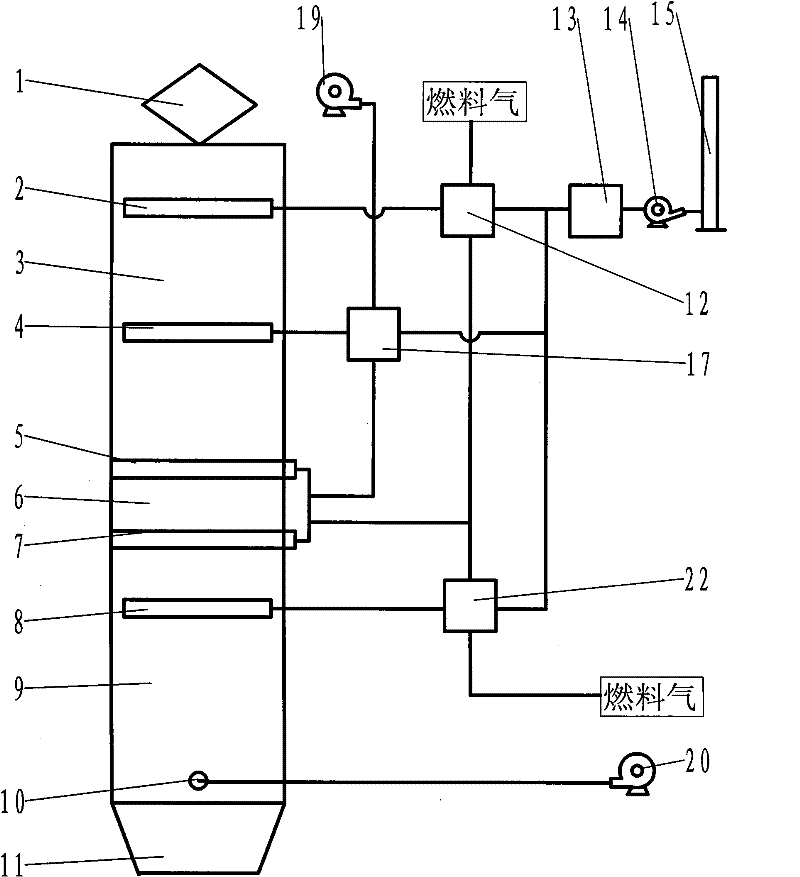

[0025] Yet another embodiment of the present invention is as image 3 As shown, the blower 19 is connected to the air inlet of the combustion beam through the high-temperature air heat exchanger 17, and the fuel gas pipeline is connected to the fuel gas inlet of the combustion beam through the flue gas / fuel gas heat exchanger 12 and the cooling air / fuel heat exchanger 22 respectively. The combustion-supporting air generated by the blower reaches 700-800°C after being heat-exchanged by the high-temperature air heat exchanger 17, and the temperature of the fuel gas reaches 250°C after heat-exchanging through the flue gas / fuel gas heat exchanger 12 and the cooling air / fuel heat exchanger 22 respectively. ~300°C. The preheated fuel gas and combustion-supporting air are mixed and burned through the pipeline in the combustion beam body to the burner to produce high-temperature calcined limestone materials at 1350-1450 °C. The flue gas extracted from the upper suction beam passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com