Sampling method of partial circular arc cambers for nuclear grade stainless steel forgings

A surface arc, stainless steel technology, applied in the field of machining, can solve the problems that the material properties cannot be guaranteed to be similar, increase the size and weight of forgings, affect the performance of the body, etc., achieve good sampling consistency, reduce the size of forgings, and improve material utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

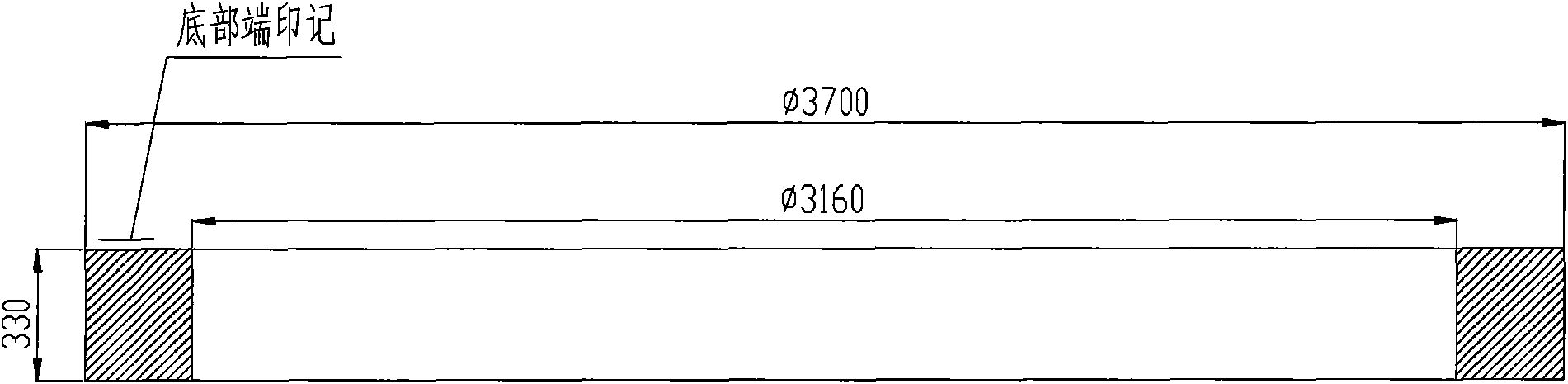

[0044] Such as figure 1 As shown, the local curved surface arc sampling method of nuclear grade stainless steel forgings of the present invention adopts 5 * 15m CNC dragon milling, and carries out curved surface arc sampling on nuclear grade stainless steel forgings by the method of numerical control programming:

[0045] This example is in figure 1 Sampling from the forging of the compression spring of the internals shown:

[0046] 1. Draw a line;

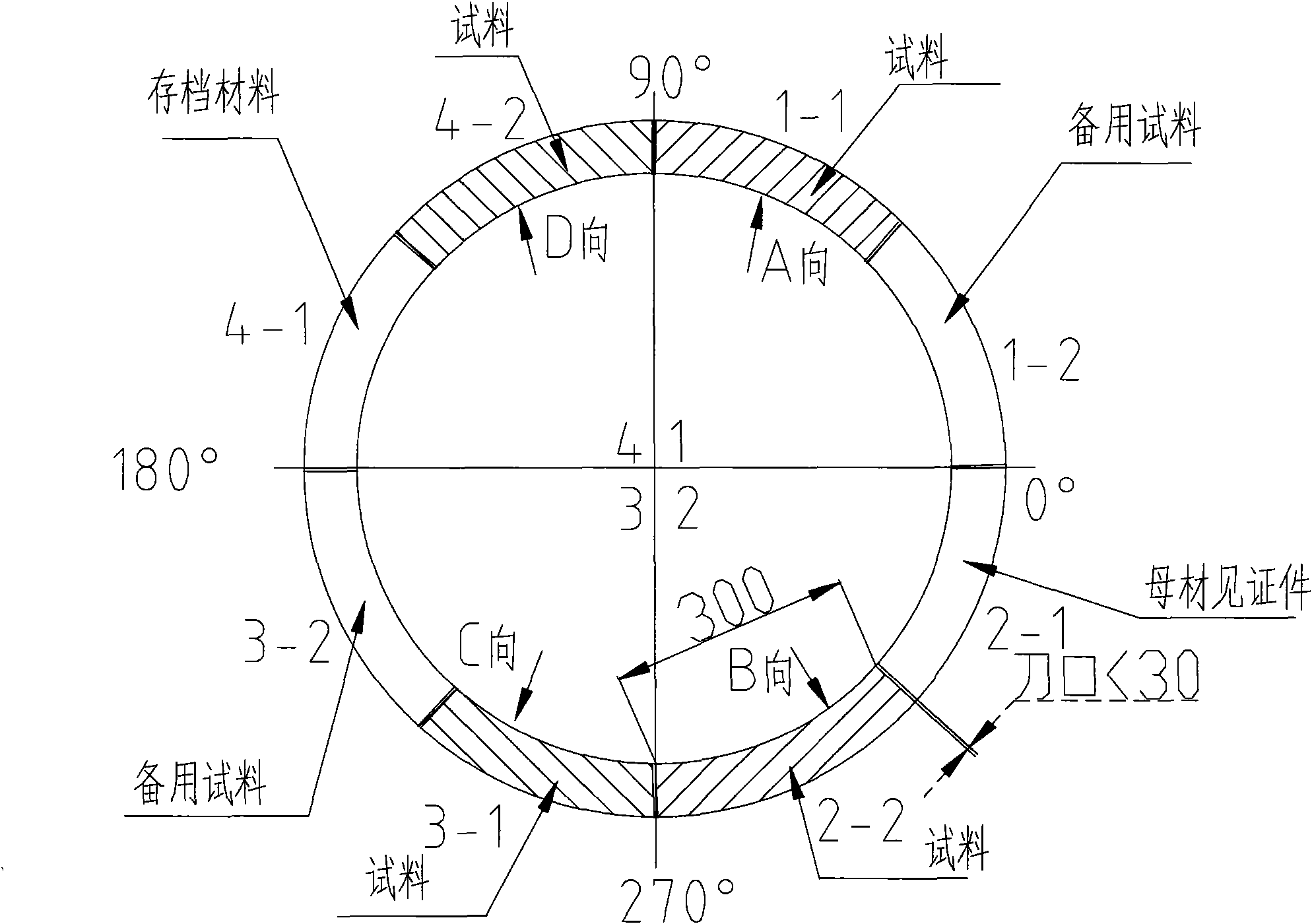

[0047] On the two end faces of the heat-treated workpiece, draw the corresponding center cross lines respectively, and mark 0°, 90°, 180°, and 270° marks counterclockwise, such as figure 2 shown.

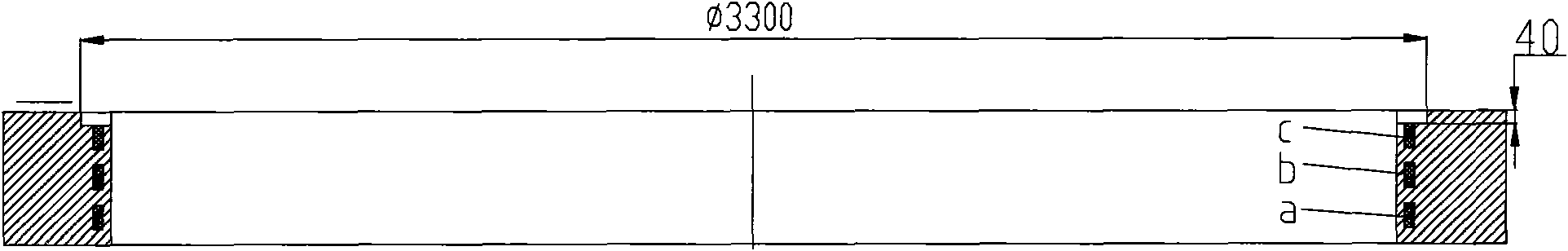

[0048] Draw the sample area lines on the two end faces respectively, figure 2 Draw 4 arc samples with a chord length of 300+2×30mm (the chord length of the sample is 300mm, and leave a margin of 30mm at both ends as the margin of the knife edge); the diameter of the arc is not greater than φ3300mm, and the knife edge <30mm ; 4 sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com