Method for reducing injury caused by laser peeling

A laser lift-off and laser scanning technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as low yield, inability to fully realize the advantages of vertical structure LEDs, and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

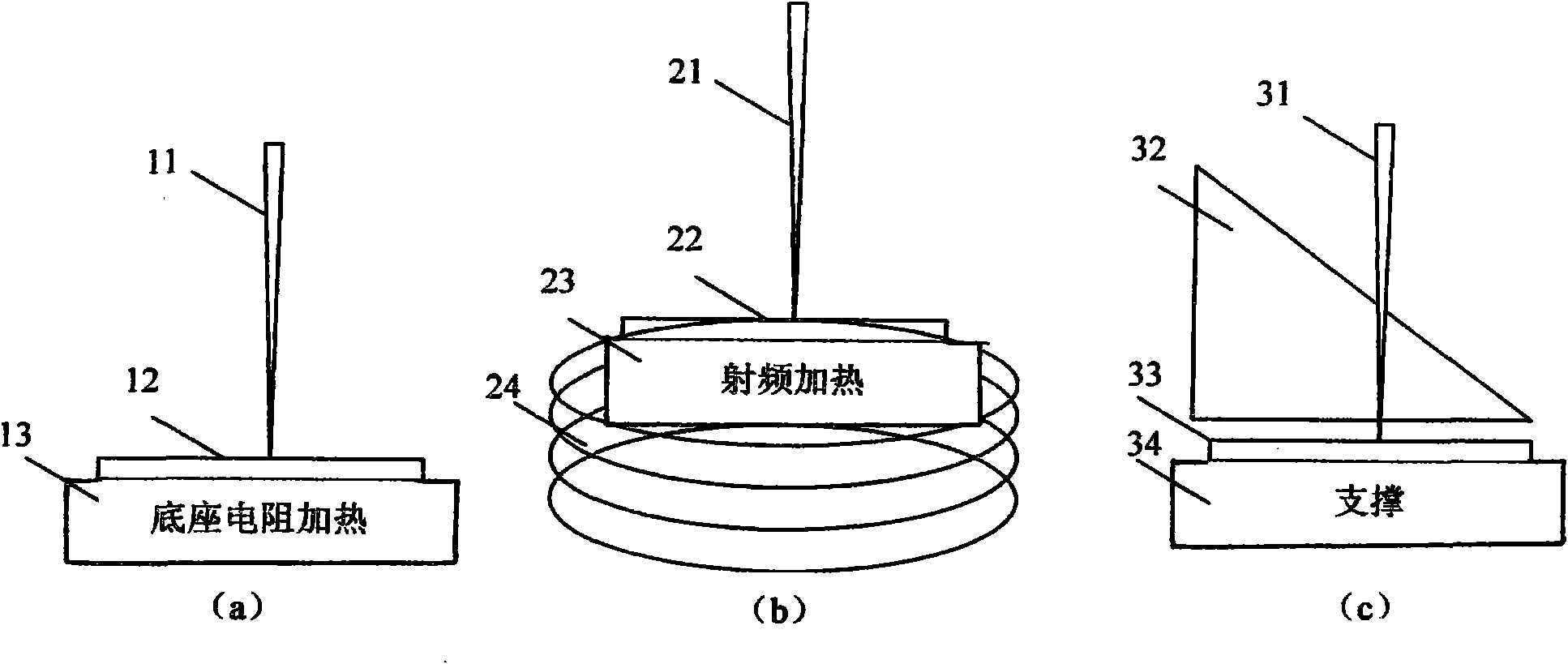

[0027] GaN / InGaN multiple quantum well LED structure on sapphire substrate, using such as figure 1 (a) shows the resistance heating of the bottom plate, 13 is the heated bottom plate, which is heated by resistance wire, and 12 is the GaN / InGaN multi-quantum well LED epitaxial wafer on the sapphire, which is placed on the heating plate 13, and reaches an appropriate temperature by heat conduction The temperature of the epitaxial wafer 12 can be obtained by thermocouple or non-contact infrared, laser temperature measurement, etc., and the stripping is carried out by scanning the laser 11 of the laser stripping equipment.

Embodiment 2

[0029] HVPE GaN thick film on sapphire substrate, using as figure 1 In the radio frequency heating shown in (b), 24 is a heated radio frequency coil, 23 is a heating base plate, which is heated by induction, and 22 is a GaN / InGaN LD epitaxial wafer on sapphire, which is placed on the heating base plate 23 and is induced by the heating base plate 23 After heating, the temperature of the epitaxial wafer 22 can be obtained through heat conduction to the epitaxial wafer 22. The temperature of the epitaxial wafer 22 can be obtained by thermocouple or non-contact infrared, laser temperature measurement, etc., and the self-supporting GaN substrate can be obtained by scanning with the laser 21 of the laser lift-off equipment. end.

Embodiment 3

[0031] GaN / AlGaN HEMT structures on sapphire substrates, using e.g. figure 1 The external light source shown in (c) is heated, 32 is the light source of external heating, 34 is the support base plate, 33 is the GaN / AlGaNHEMT epitaxial wafer on the sapphire, is placed on the support base plate 34, is heated by the external heating light source 32 epitaxial wafer 33 reaches For an appropriate temperature, the temperature of the epitaxial wafer 33 can be obtained by thermocouple or non-contact infrared, laser temperature measurement, etc., and the stripping is carried out by scanning the laser 31 of the laser stripping equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com