Fuel gas weak blast wave dust-cleaning deduster

A technology of explosive wave and dust collector, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of reduced dust cleaning effect, difficult matching application of dust collectors, and low energy utilization rate, so as to avoid Condensation and freezing damage, saving primary energy, highlighting the effect of environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

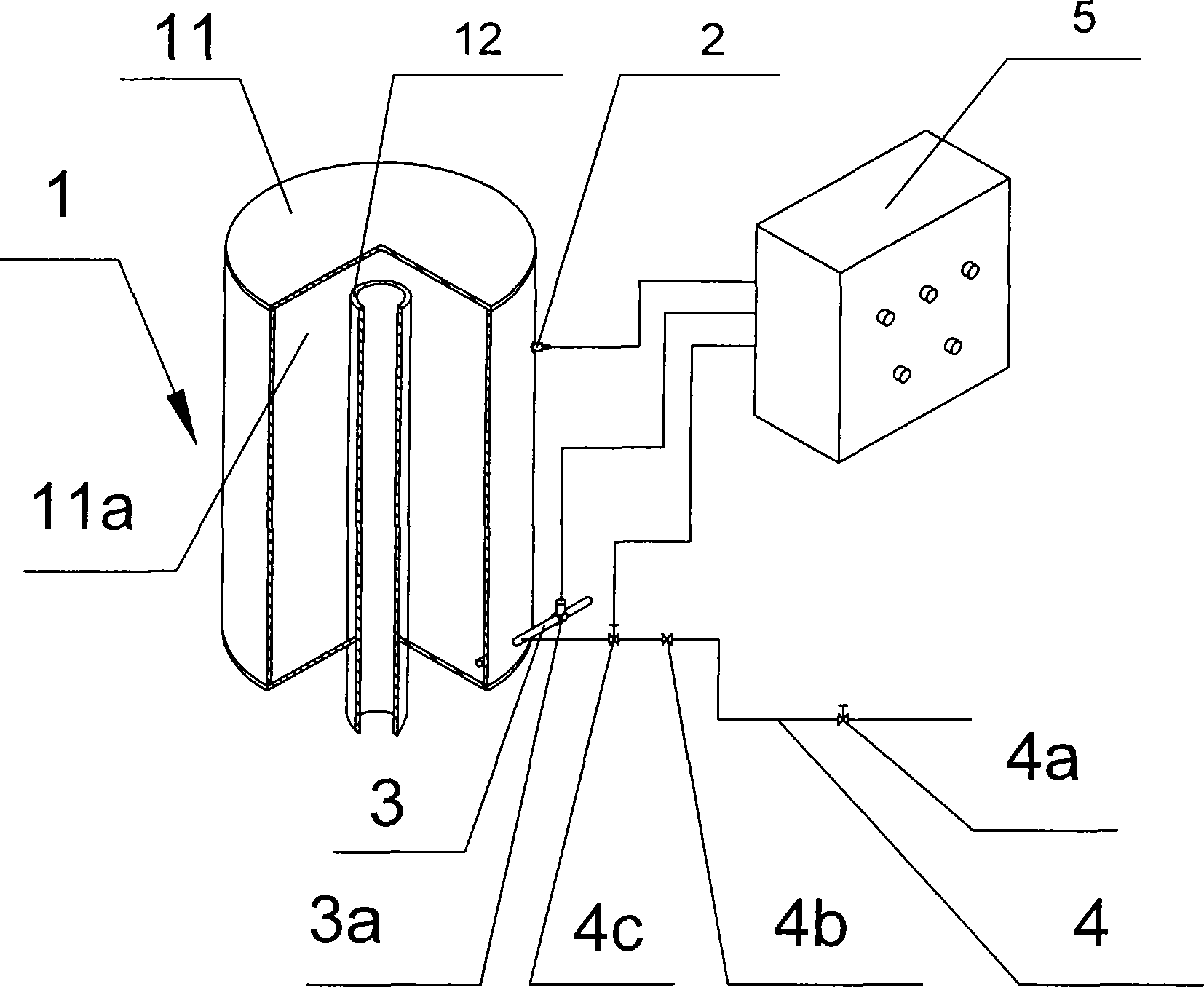

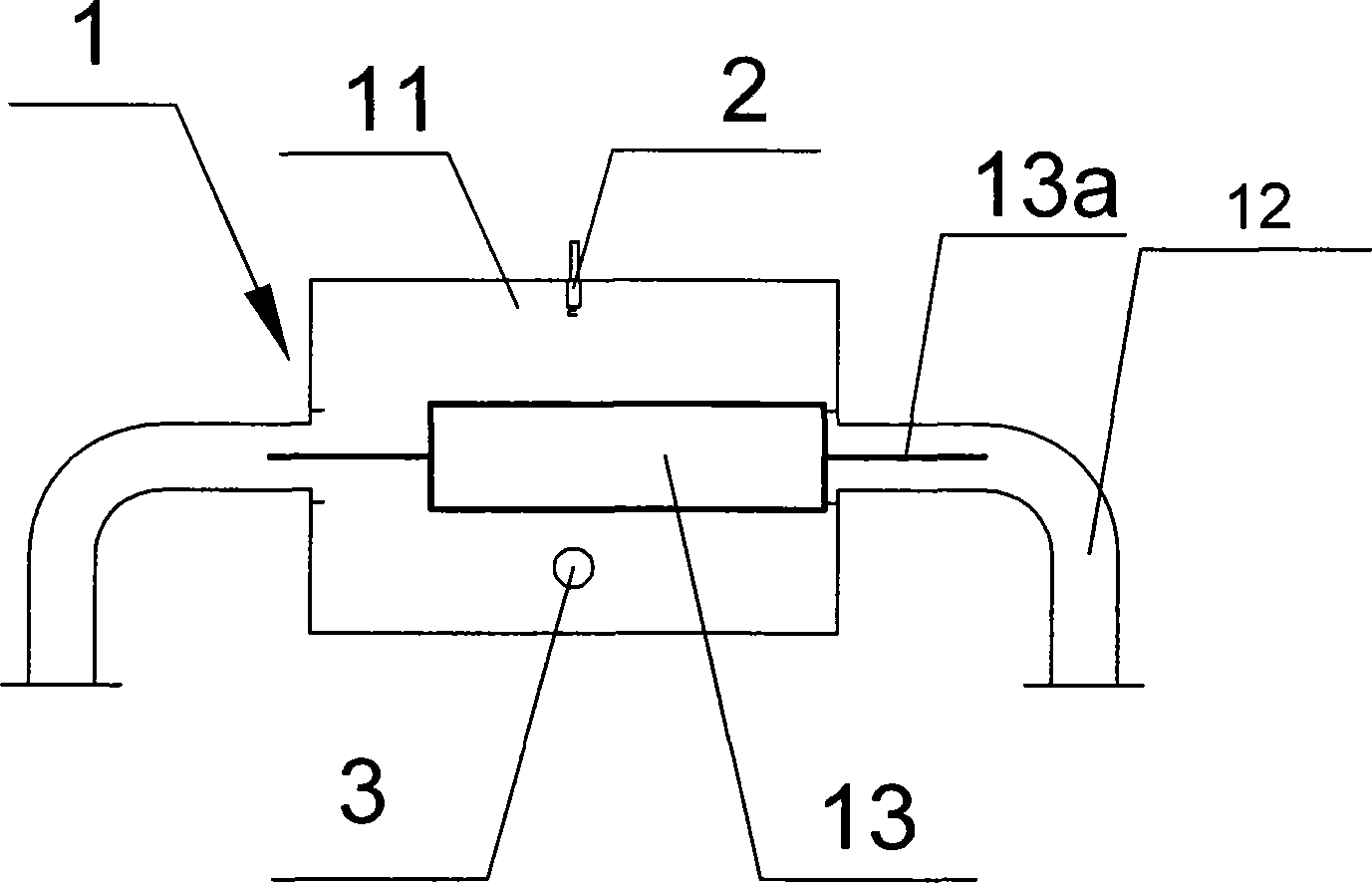

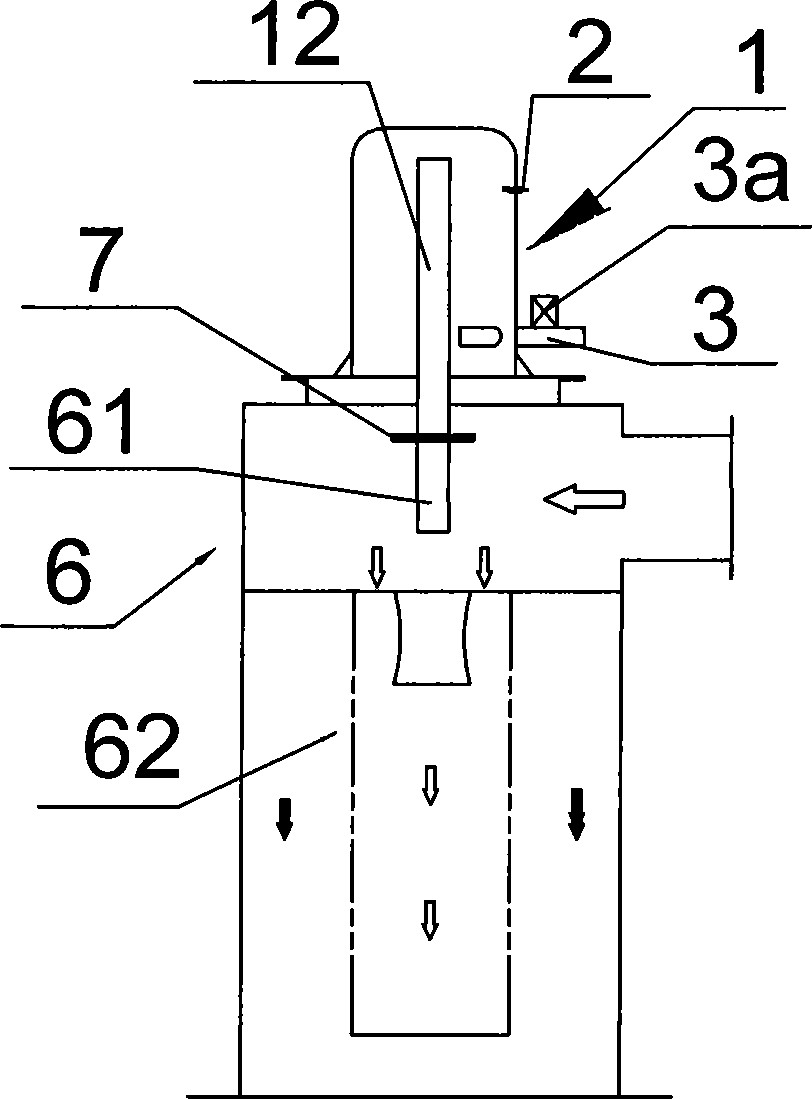

[0029] Such as figure 1 with image 3 Shown, a kind of small-sized stand-alone gas weak explosion wave dust removal dust collector, it comprises: a box body 6, a filter unit 62 and a blowing device 61, and this filter unit 62 comprises one or more filters that carry out dust removal at the same time bag or filter cartridge, the top of the box body 6 is provided with a weak detonation wave reactor 1, and the injection pipe 12 of the weak detonation wave reactor 1 is connected with the injection device 61 in the box body 6 through a flange, Figure 3a It is a gas weak explosive wave reactor that simultaneously provides cleaning for multiple filter bags or filter cartridges of a filter unit 62. The injection pipe 12 of the gas weak explosive wave reactor 1 and the multiple injection devices in the box 6 61 are connected by pipelines. This gas weak explosive wave reactor 1 comprises a tank body 11 and a spray pipe 12, and this tank body 11 is closed shape, and its inside is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com