Special spinning machine for numerical control die-free fan

A technology of spinning machines and mold fans, which is applied in the field of special spinning machines for CNC moldless fans, can solve the problems of complicated installation and debugging, time-consuming and laborious production cycle, and low precision of fan parts, so as to improve production efficiency and product quality, save The effect of high production cost and product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with the accompanying drawings.

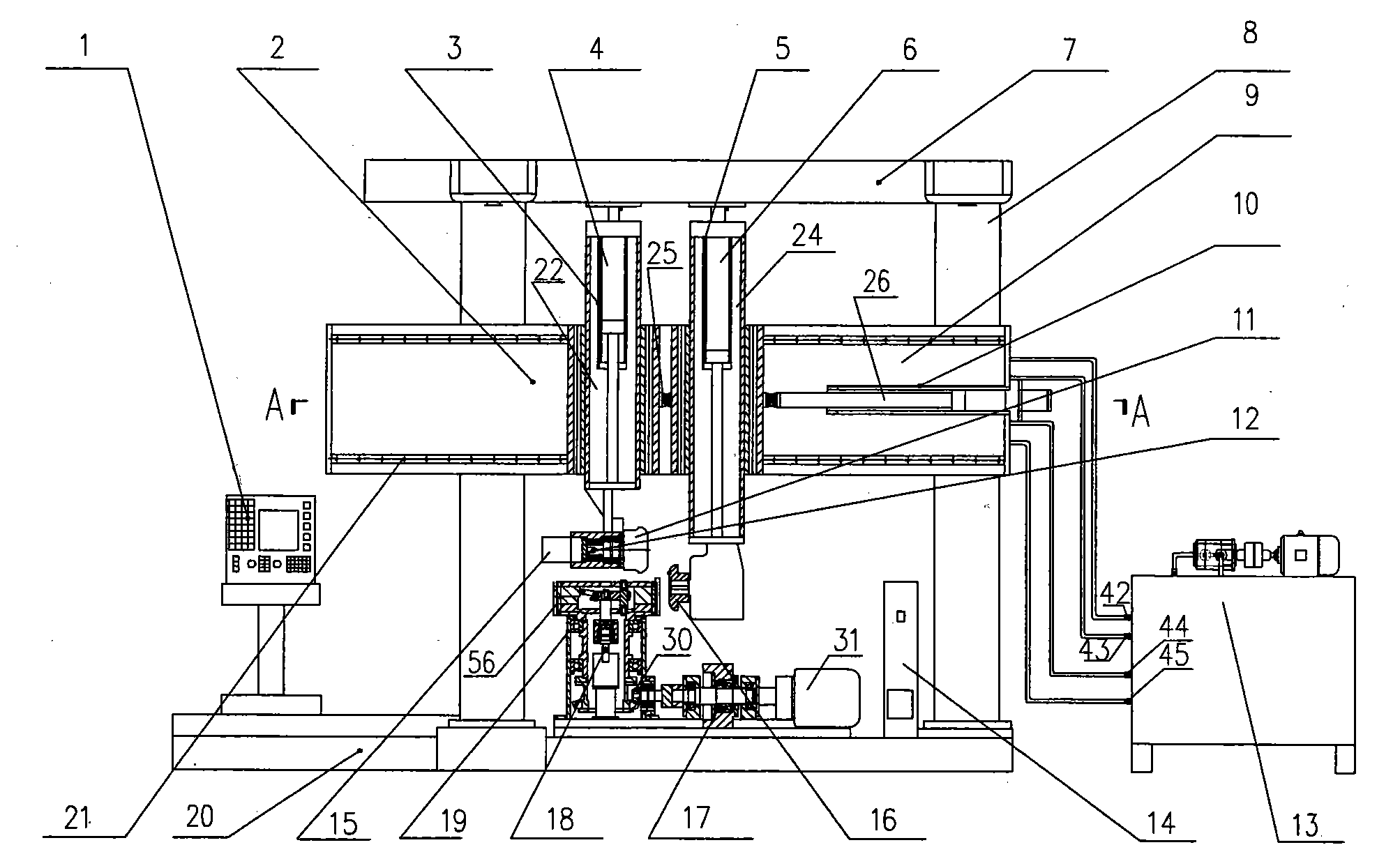

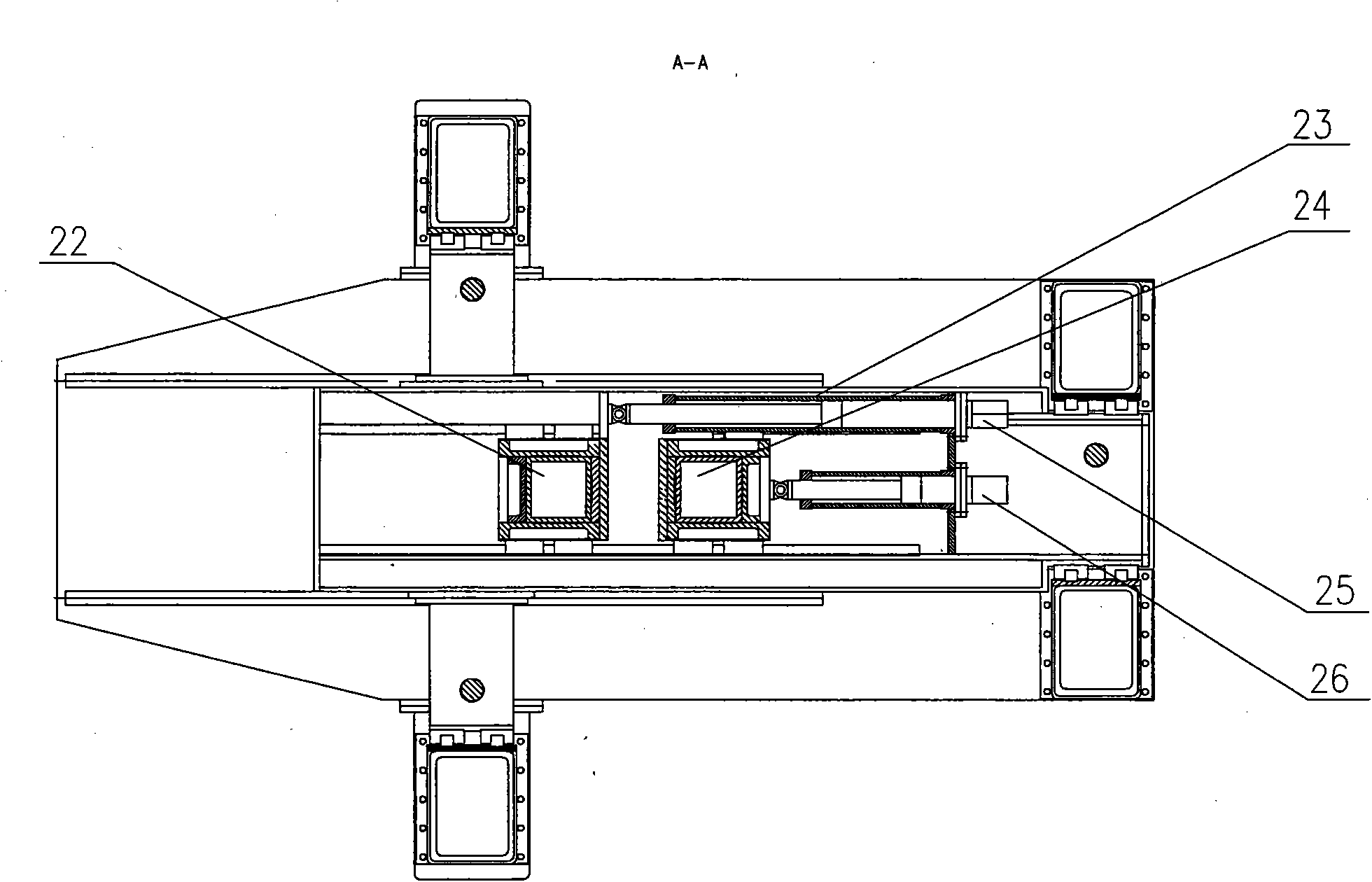

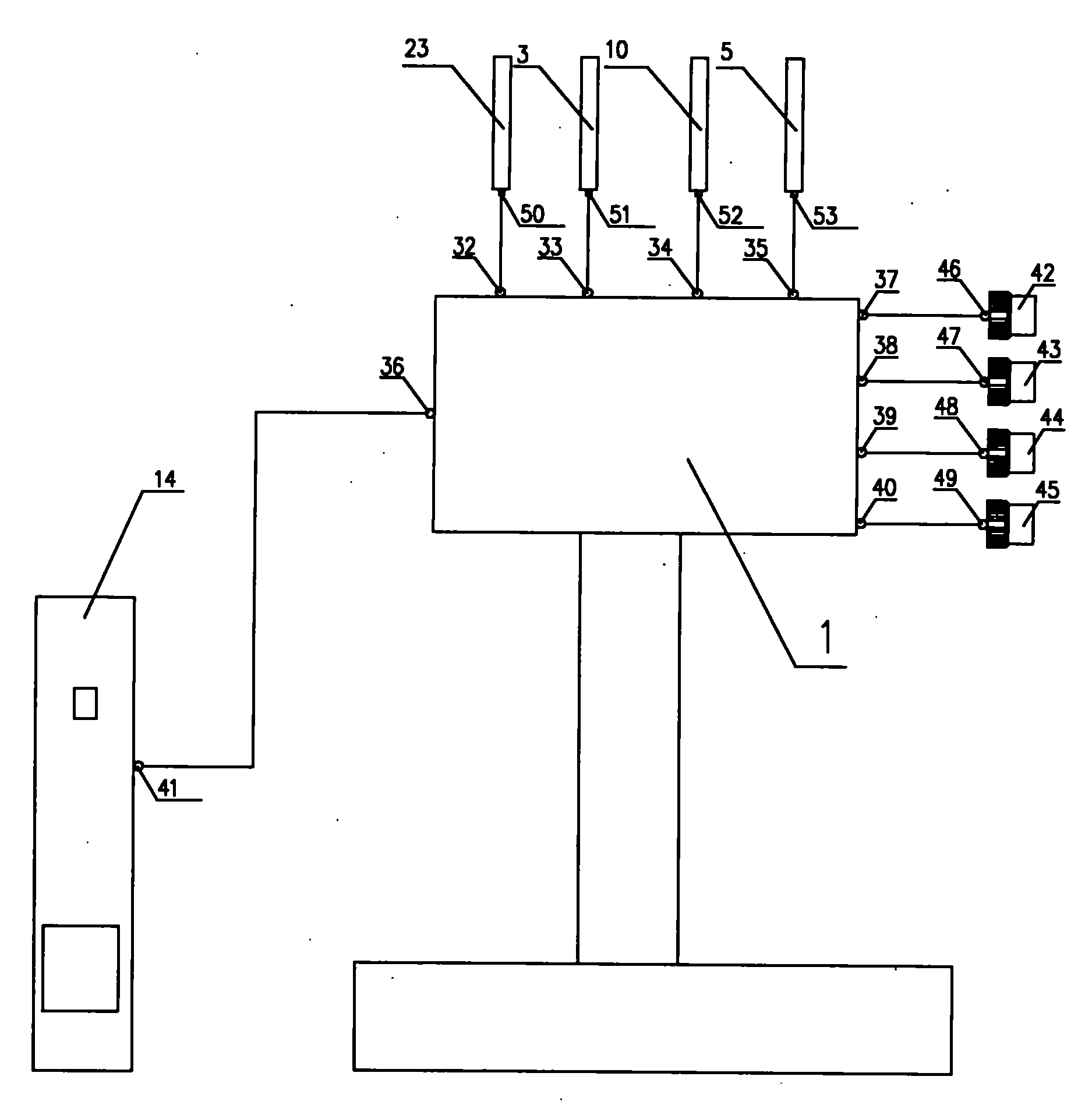

[0014] like figure 1 , figure 2 and image 3 As shown, the CNC moldless fan special spinning machine includes a CNC system 1 and a base 20 on which a vertically upward main shaft 18 is fixed, the upper part of the main shaft 18 and the expansion clamping device arranged on the base 20 The rotating head 56 of 19 is connected, the bottom of the main shaft 18 is connected with the main shaft motor 31 that is arranged on the base 20 through the steering structure 30, the motor shaft of the main shaft motor 31 is provided with an overrunning clutch 17, the power interface of the main shaft motor 31 and the frequency conversion The power output ports of the device 14 are connected, and the base 20 is also fixed with two vertically upward columns 8, the tops of the two columns 8 are connected with the machine top 7, and the first laterally moving brackets 2 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com