Processing method for large breadth thin stone boards and super-thin boards

A processing method and ultra-thin plate technology, applied in the field of stone processing, can solve the problems of complex processing technology, brittleness and low yield of composite layer method, so as to improve the strength and yield of plates, improve bending strength, and improve processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technological process of the large-format stone thin plate and ultra-thin plate processing method of the present invention is: stone plate → panel drying → glue brushing and compounding → splitting and splitting → finished product thickness determination → polishing on both sides → edge trimming and chamfering → composite plate decomposition → Finished product, specifically including the following steps:

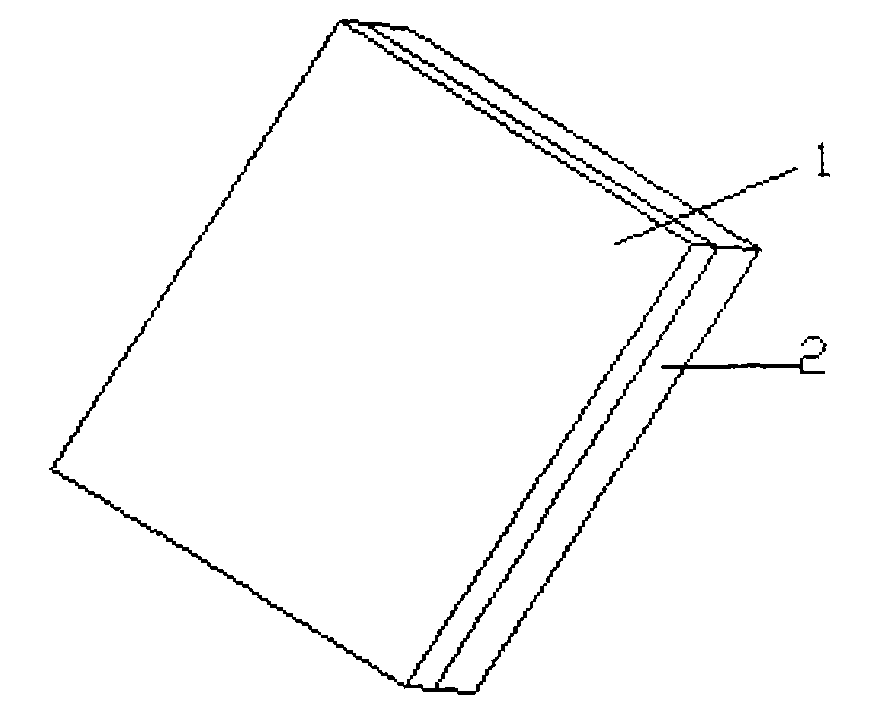

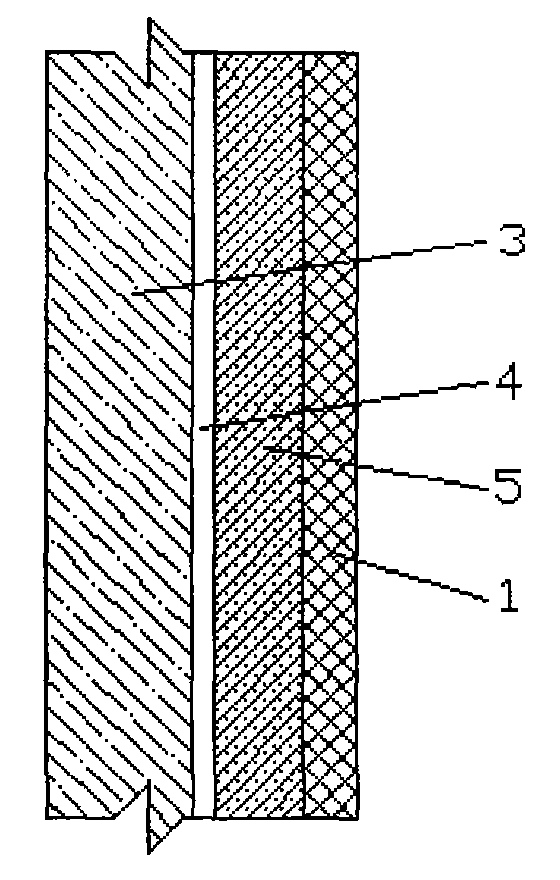

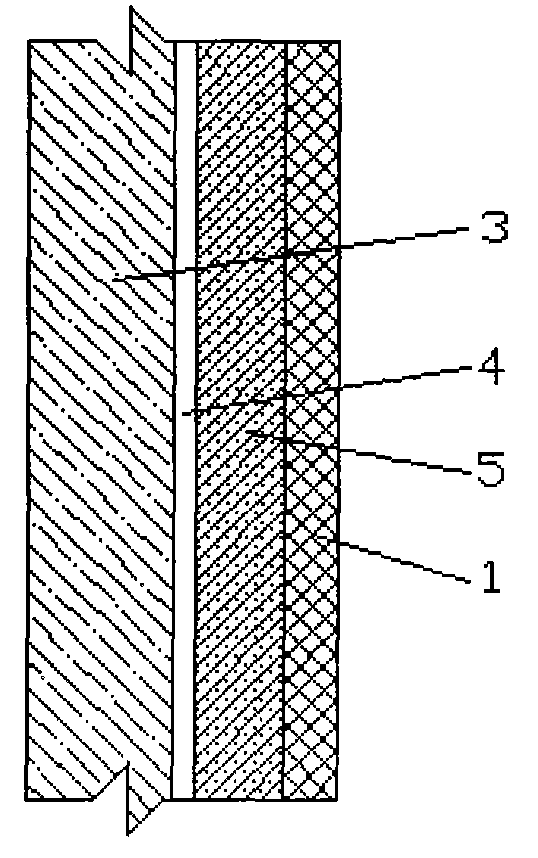

[0014] (1) if figure 1 As shown, the stone slab 2 after trimming and forming and determining the thickness is bonded and compounded with a matrix through an adhesive to form a single-sided composite stone matrix composite slab. The stone slab 2 is trimmed and formed by the trimming machine, so that the shape and size of the stone slab are unified, and the thickness is determined by the thickness gauge to ensure that the thickness is the same. After the stone plate 2 is dried by a dryer, glue is applied. The matrix 1 can be a metal plate with a thickness of ≥3 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com