Expansion chamber resistant noise-reducing structure for automotive power steering high-pressure oil pipe

A technology for automotive power steering and high-pressure oil pipes. It is applied to fluid steering mechanisms, pipes, rigid pipes, etc. It can solve the problems of steering noise, strong humming, and affecting the comfort of vehicle control. It achieves obvious effects, eliminates noise, The effect of changing the amount of silencer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

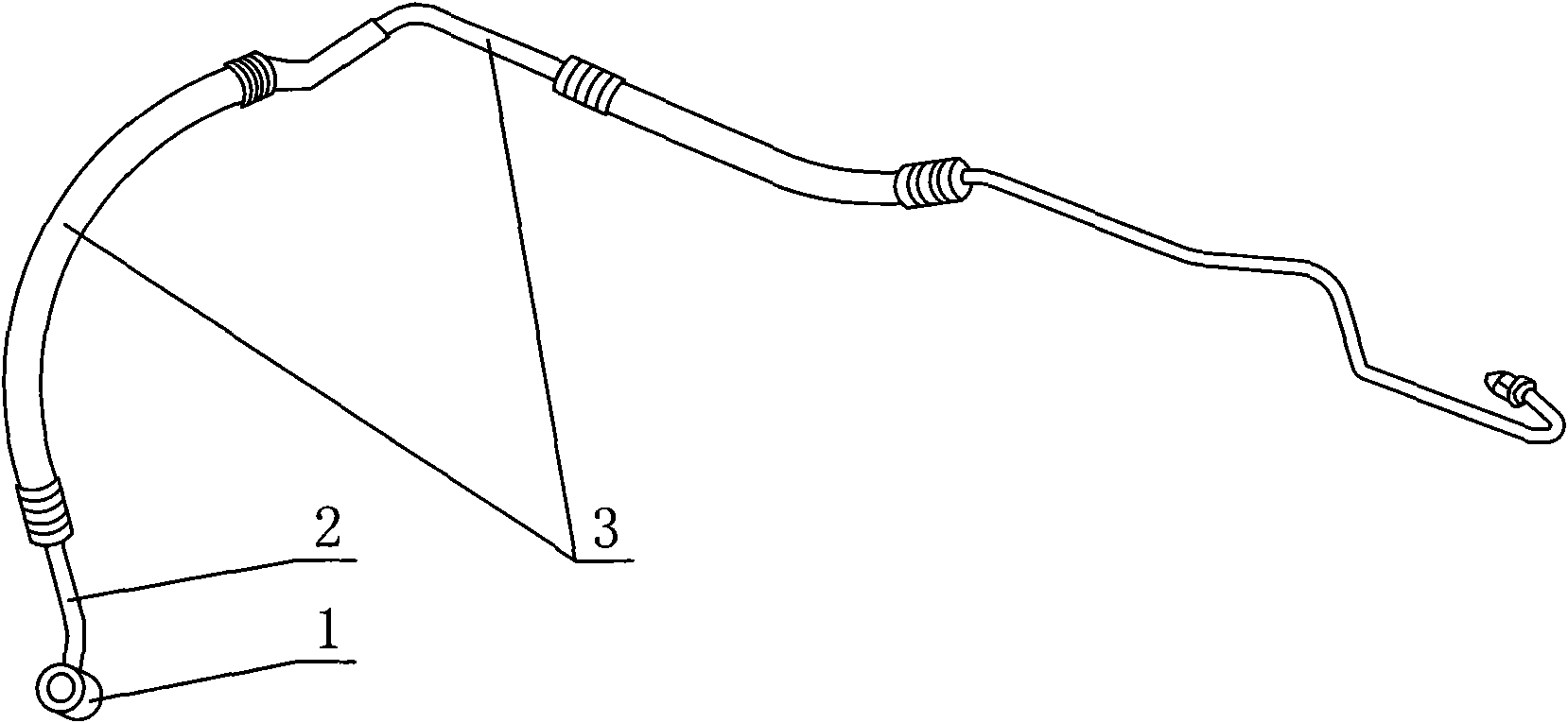

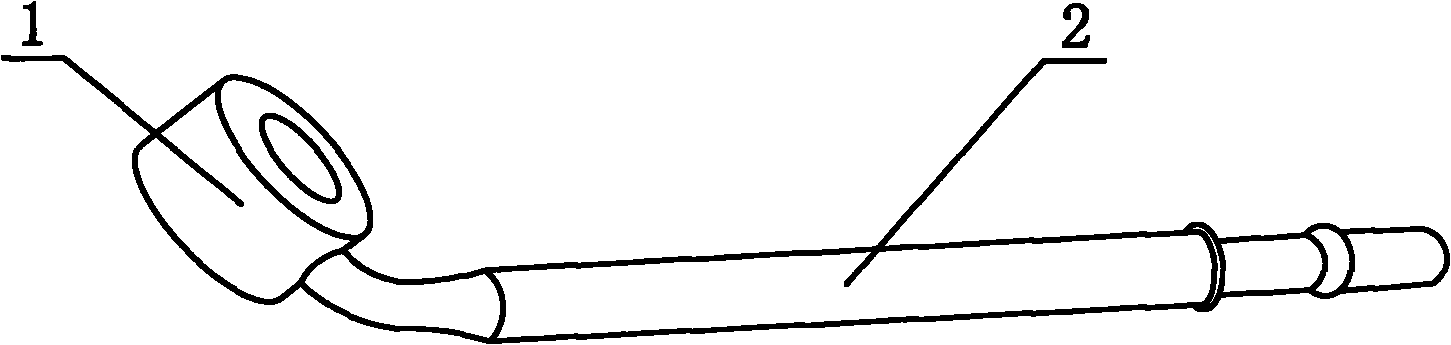

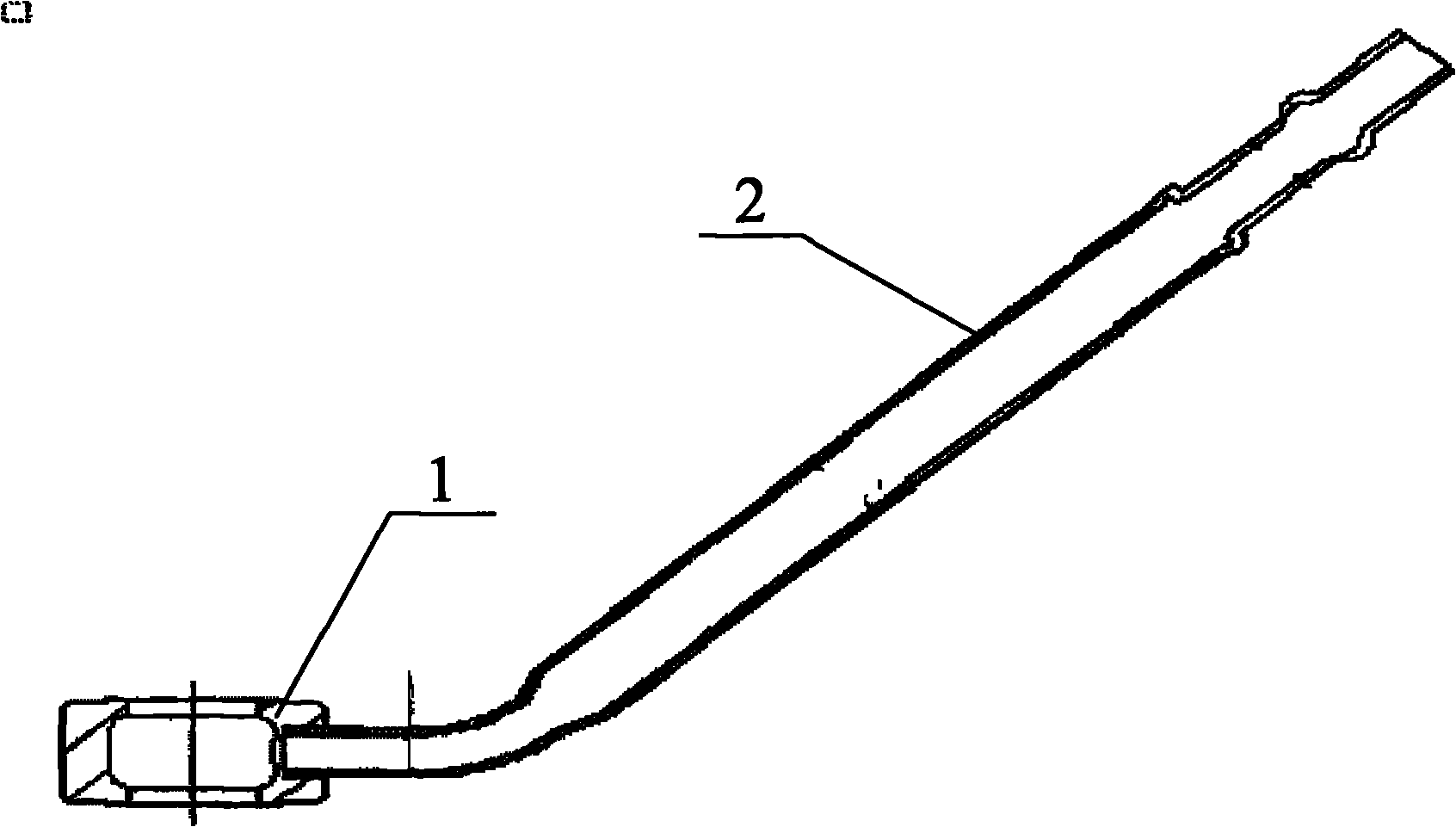

[0014] Such as Figure 1-3 As shown, the expansion chamber anti-muffling structure of the automobile power steering high-pressure oil pipe is composed of a spherical joint 1, a variable-diameter steel pipe 2, a high-pressure rubber hose, and a metal sleeve 3. The variable-diameter steel pipe 2 has a small outer diameter at both ends and a middle outer diameter. Large, the transition between different segments with small and large outer diameters is smooth and integrated.

[0015] One end of the variable-diameter steel pipe 2 is connected to the ball joint 1 through high-frequency welding, and the other end is locked with the high-pressure rubber hose and the metal sleeve 3 to form a sealed structure.

[0016] The spherical joint 1 is machined and formed by a numerical control machine tool, and the variable-diameter steel pipe 2 is formed by cold extrusion and stretching with a special mold.

[0017] The expansion chamber anti-muffling structure of the automobile power steerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com