Unblocking agent for polymer gel profile control agent

The technology of profile control agent and blocking agent is applied in the field of blocking agent for polymer gel profile control agent, which can solve the problems of slow breaking speed and insufficient breaking of glue, and achieve fast breaking speed and breaking ability of glue. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

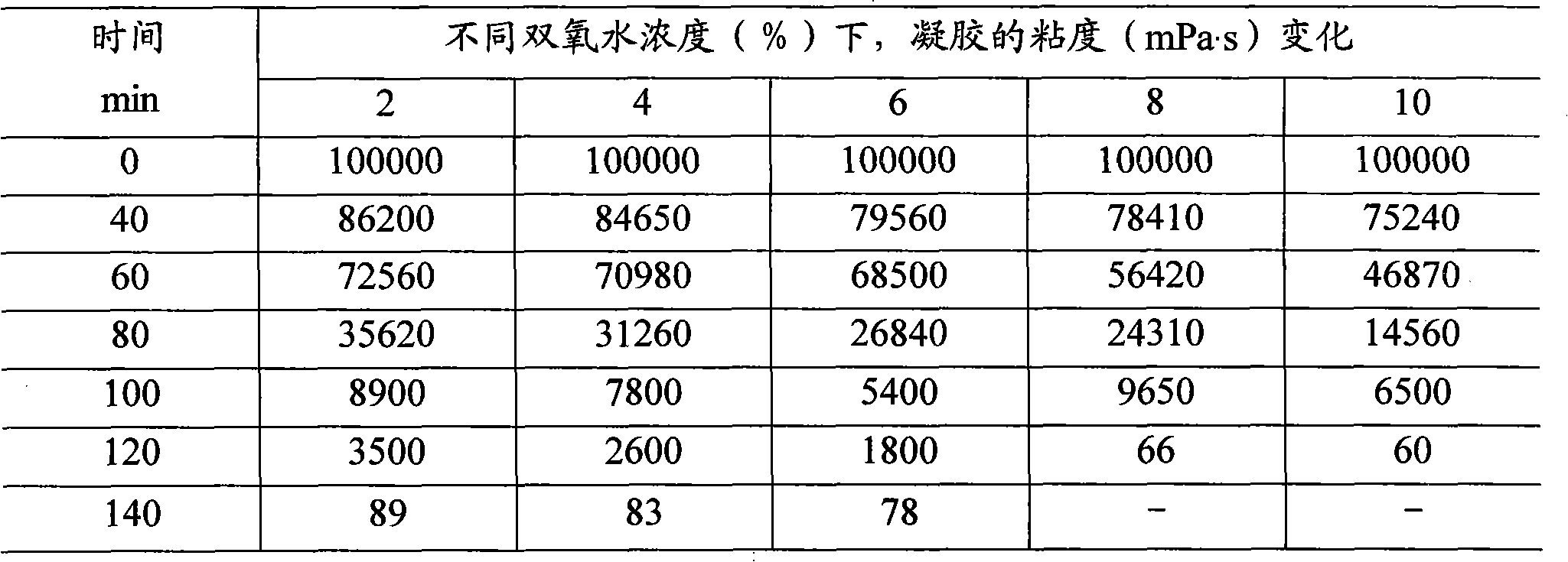

[0008] Embodiment 1 Hydrogen peroxide is to the gel breaking experiment of gel

[0009] Take an equal volume of the gel system that has been gelled, and then add 2%, 4%, 6%, 8%, and 10% hydrogen peroxide solution at a concentration twice that of the gel volume, put it in a constant temperature water bath, and perform it every 20 minutes Viscosity measurement, until the gel is broken, measure the viscosity of the gel system after curing for different times.

[0010] The test results of the blocking release agent for the polymer gel profile control agent in this example are shown in Table 1 below.

[0011] The gel breaking data of table 1 hydrogen peroxide

[0012]

[0013] It can be seen from Table 1 that the gel breaking of hydrogen peroxide is obvious, and as the concentration increases, the gel breaking time and speed gradually increase. When the hydrogen peroxide concentration reached 8%, the gel began to break after 2 hours.

Embodiment 2

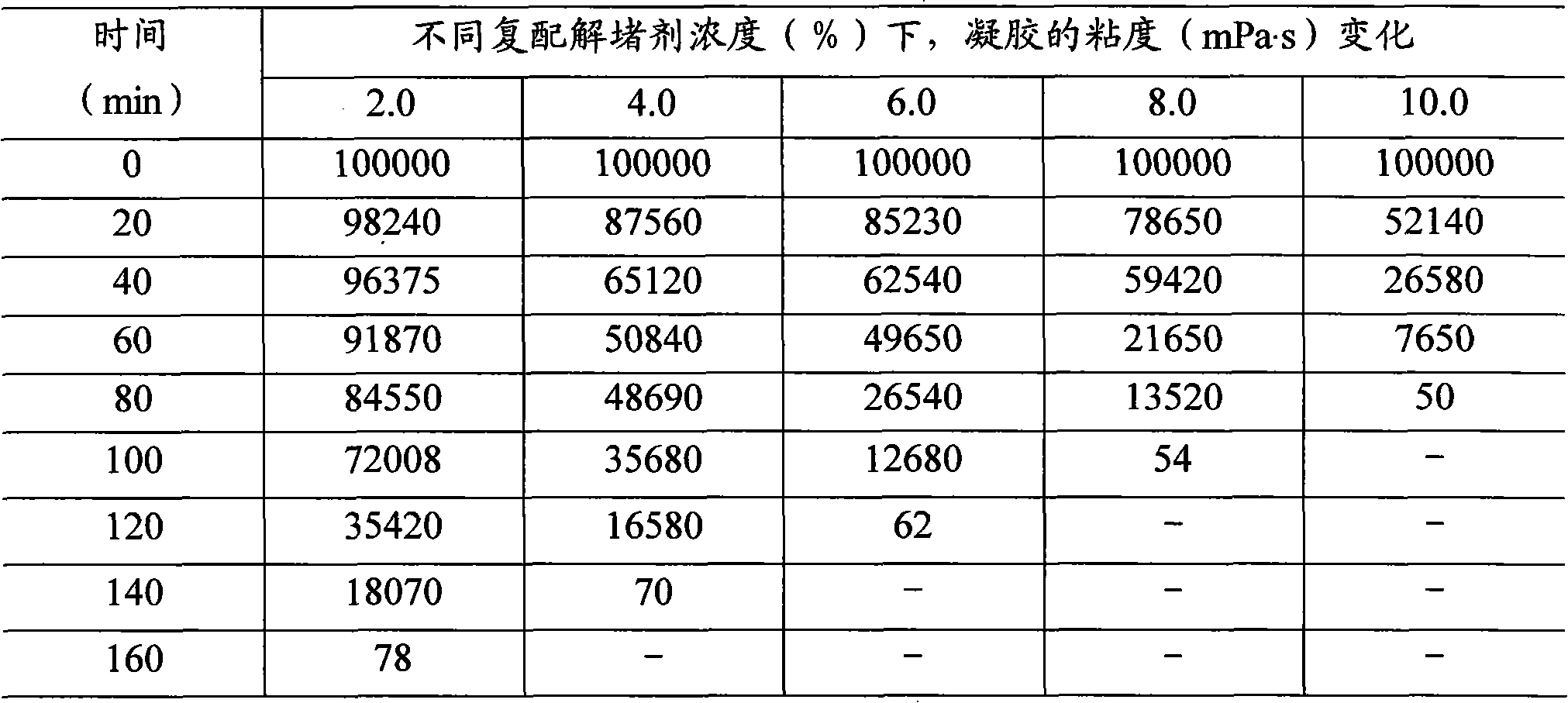

[0014] Example 2 Hydrogen peroxide and hydrochloric acid compound solution to gel breaking experiment

[0015] Take an equal volume of the gel system that has been gelled, and then add respectively 2%, 4%, 6%, 8%, and 10% compound plugging remover solutions with a concentration twice the volume of the gel, and put it in a constant temperature water bath. Viscosity measurement was performed every 20 minutes until the gel was broken, and the viscosity of the gel system after curing for different time was measured.

[0016] The test results of the plug-releasing agent for the polymer gel profile control agent in this embodiment are shown in Table 2 below.

[0017] Table 2 The gel-breaking data of the compound plugging remover (15% hydrogen peroxide+15% hydrochloric acid, the balance being water. The percentages here are percentages by weight)

[0018]

[0019] It can be seen from the table that with the increase of the concentration of the compound plugging remover solution, ...

Embodiment 37

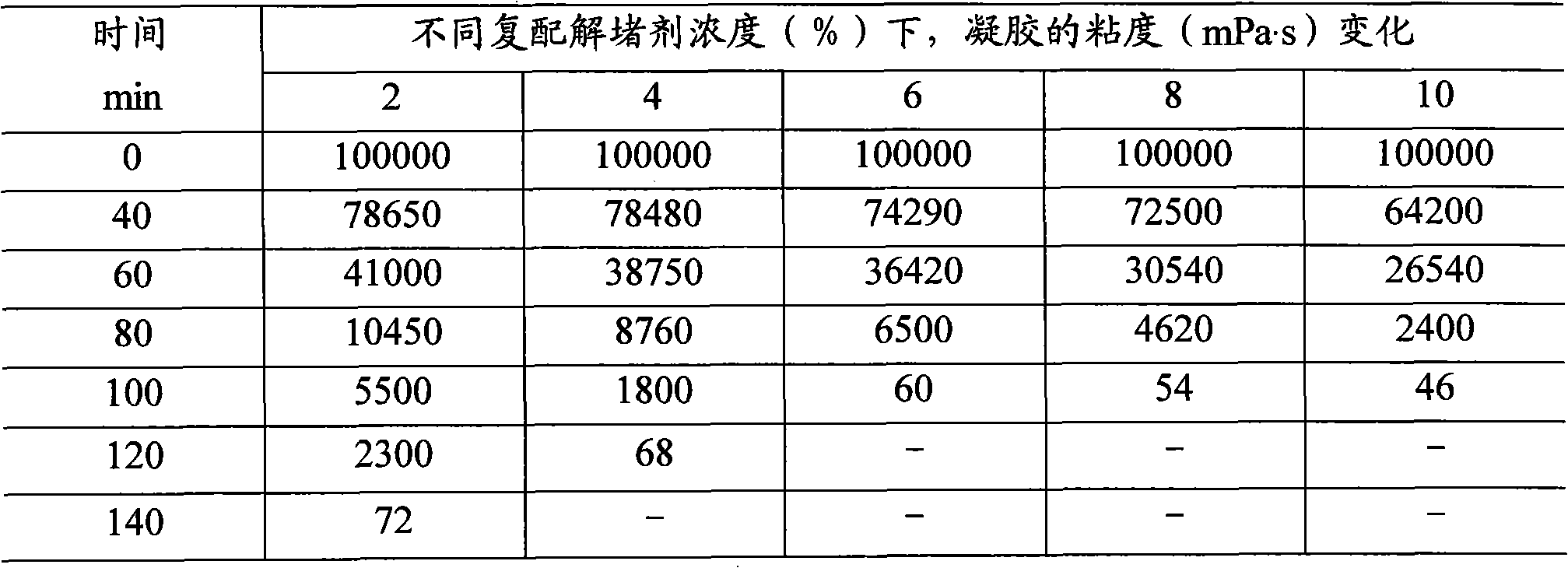

[0020] Example 37.5% hydrogen peroxide and 22.5% hydrochloric acid compound solution to gel breaking experiment

[0021] Take an equal volume of the gel system that has been gelled, and then add respectively 2%, 4%, 6%, 8%, and 10% compound plugging remover solutions with a concentration twice the volume of the gel, and put it in a constant temperature water bath. Viscosity measurement was carried out every 1 hour until the gel was broken, and the viscosity of the gel system after curing for different time was measured.

[0022] The test results of the plug-releasing agent for the polymer gel profile control agent in this embodiment are shown in Table 3 below.

[0023] Table 3 The gel breaking data of the compound plugging remover (7.5% hydrogen peroxide+22.5% hydrochloric acid, the balance is water. The percentage here is weight percentage) solution

[0024]

[0025] It can be seen from the above table that the gel breaking effect of the compound plugging remover solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com