High-blast-temperature energy-saving and emission-reducing combined type preheating system for blast furnace

A combined technology of energy saving and emission reduction, applied in blast furnace details, blast furnace, blast furnace parts and other directions, can solve problems such as large flow resistance on the air side and flue gas side, deformation and burnout of heat exchange tubes, and large total weight of equipment. , to achieve the effect of saving operating energy consumption, small flow resistance, and safe and reliable system operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

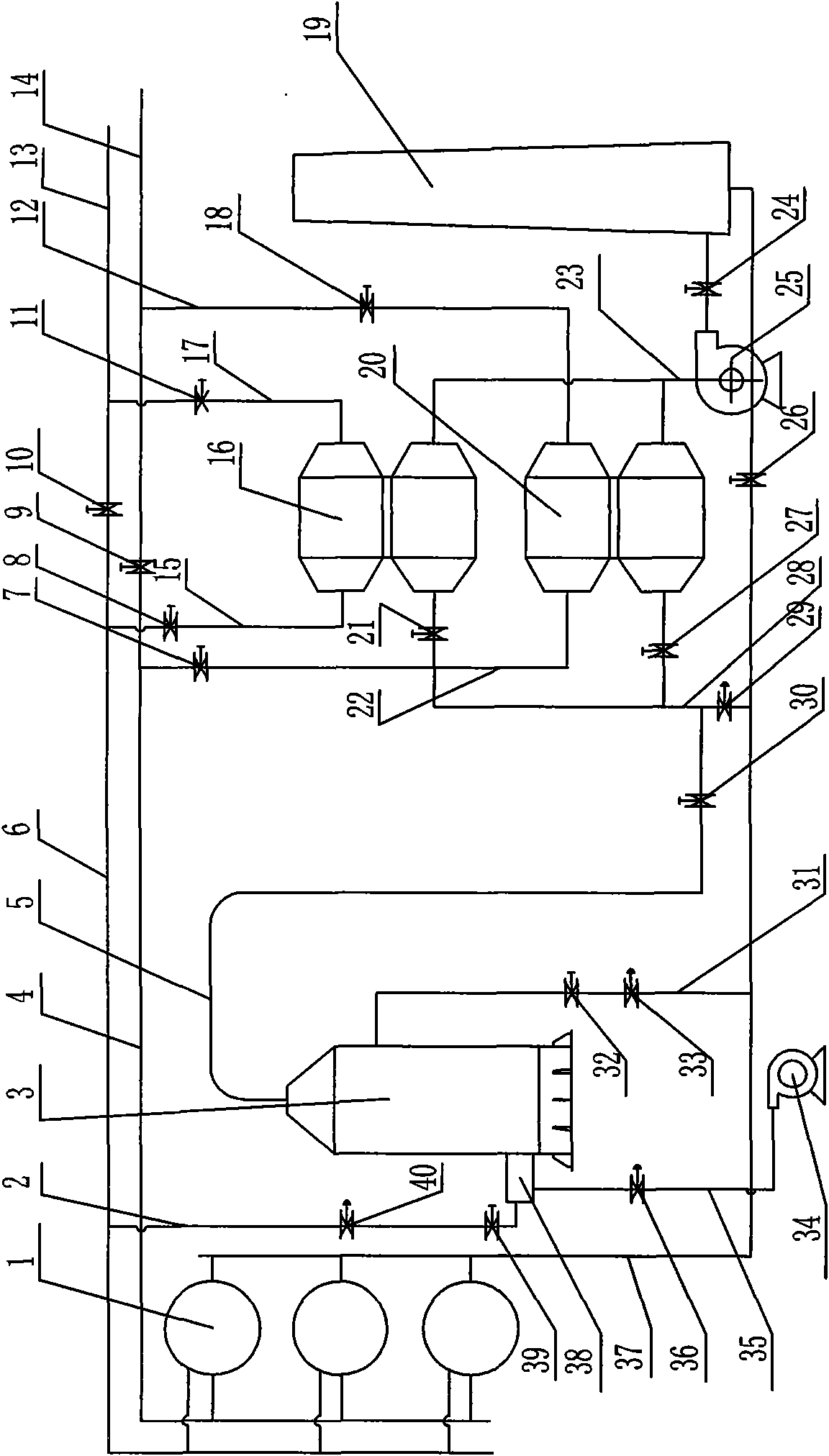

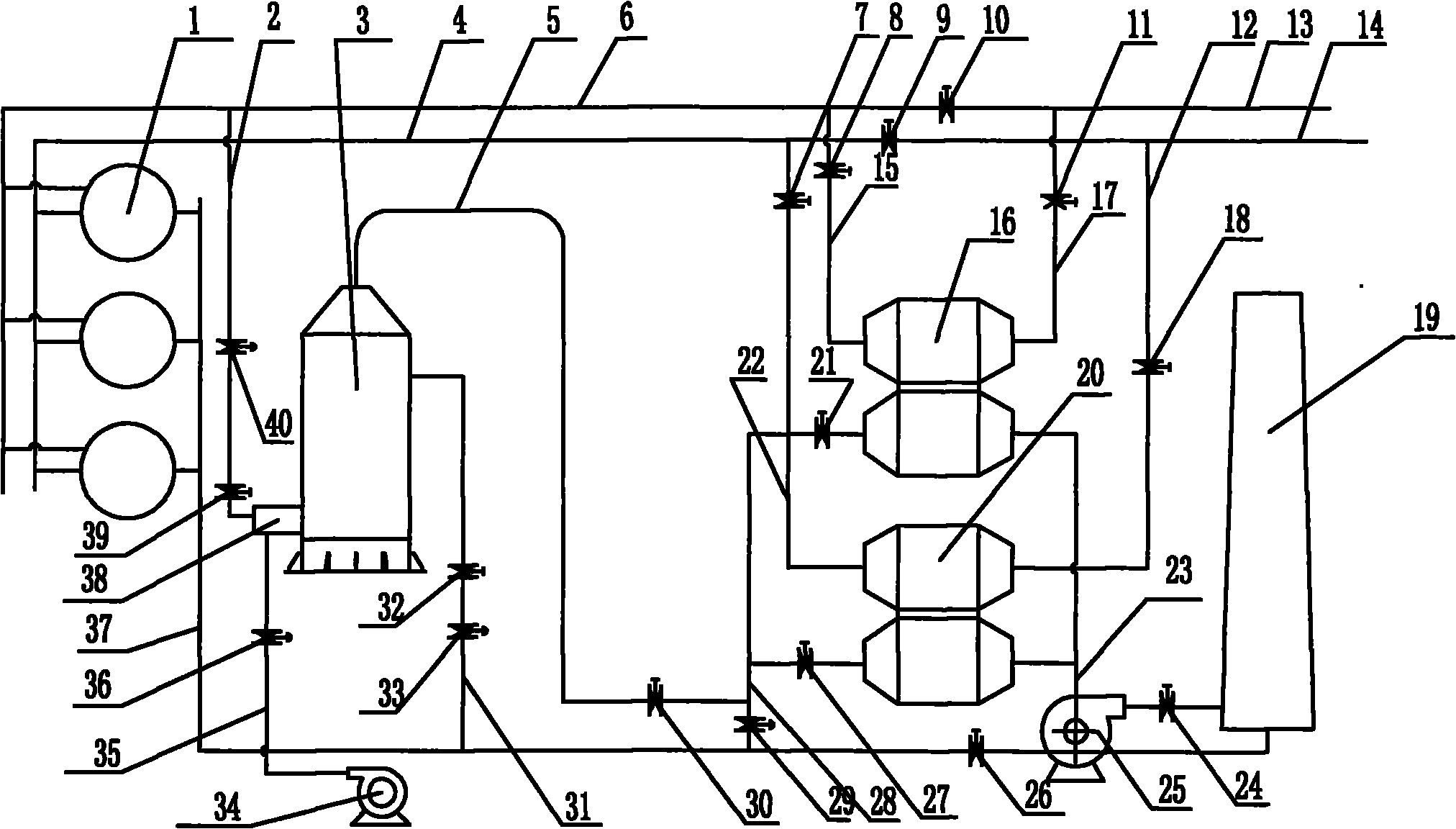

[0022] Such as figure 1 As shown, the air from the cold air main pipe 14 is connected to the air inlet of the air preheating combined heat pipe heat exchanger 20 through the air inlet pipe 12 and the air shutoff valve 18, and the air preheating combined heat pipe heat exchanger 20 The air outlet is connected to the hot air main pipe 4 through the air outlet pipe 22 and the valve 7, and is sent to the air inlet end of the hot blast stove 1. The cold air main pipe 14 and the hot air main pipe 4 are connected by a shut-off valve 15 .

[0023] The cold gas main pipe 13 is connected to the gas inlet port of the gas preheating combined heat pipe heat exchanger 16 through the gas shut-off valve 11 and the gas pipe 17, and the gas outlet of the gas preheating combined heat pipe heat exchanger 16 passes through the hot gas pipe 15 , Valve 8 is connected to hot gas main pipe 6. The cold gas main pipe 13 and the hot gas main pipe 6 are connected by a shut-off valve 10 .

[0024] Hot g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com