High-strength cold-roll phase-change plastic steel plate with good plasticity and preparation method thereof

A high-strength, plastic technology, applied in the direction of temperature control, etc., can solve the problem of deteriorating the surface quality of the slab, and achieve the effects of poor surface immersion plating, good plasticity, and improved welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

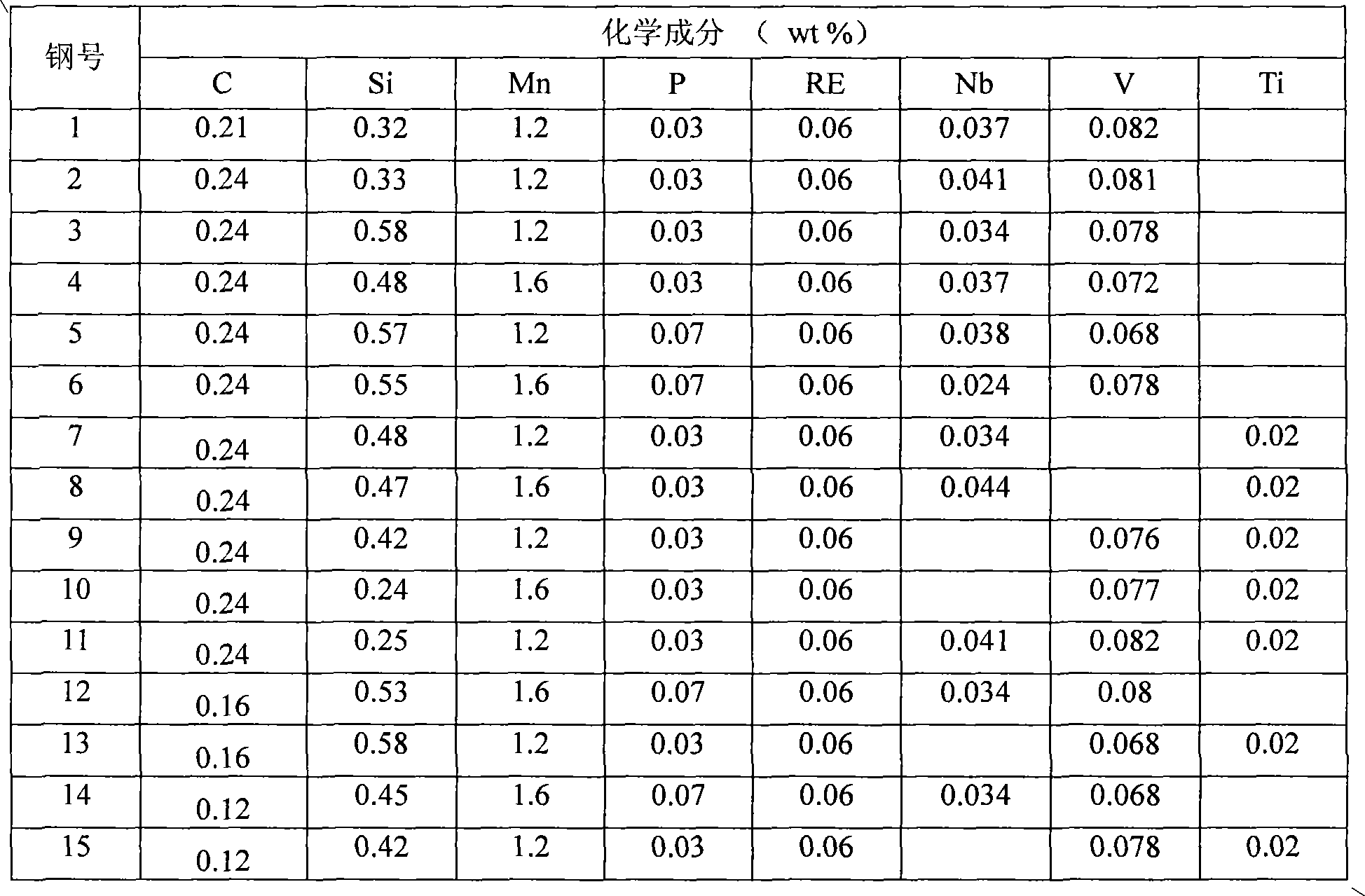

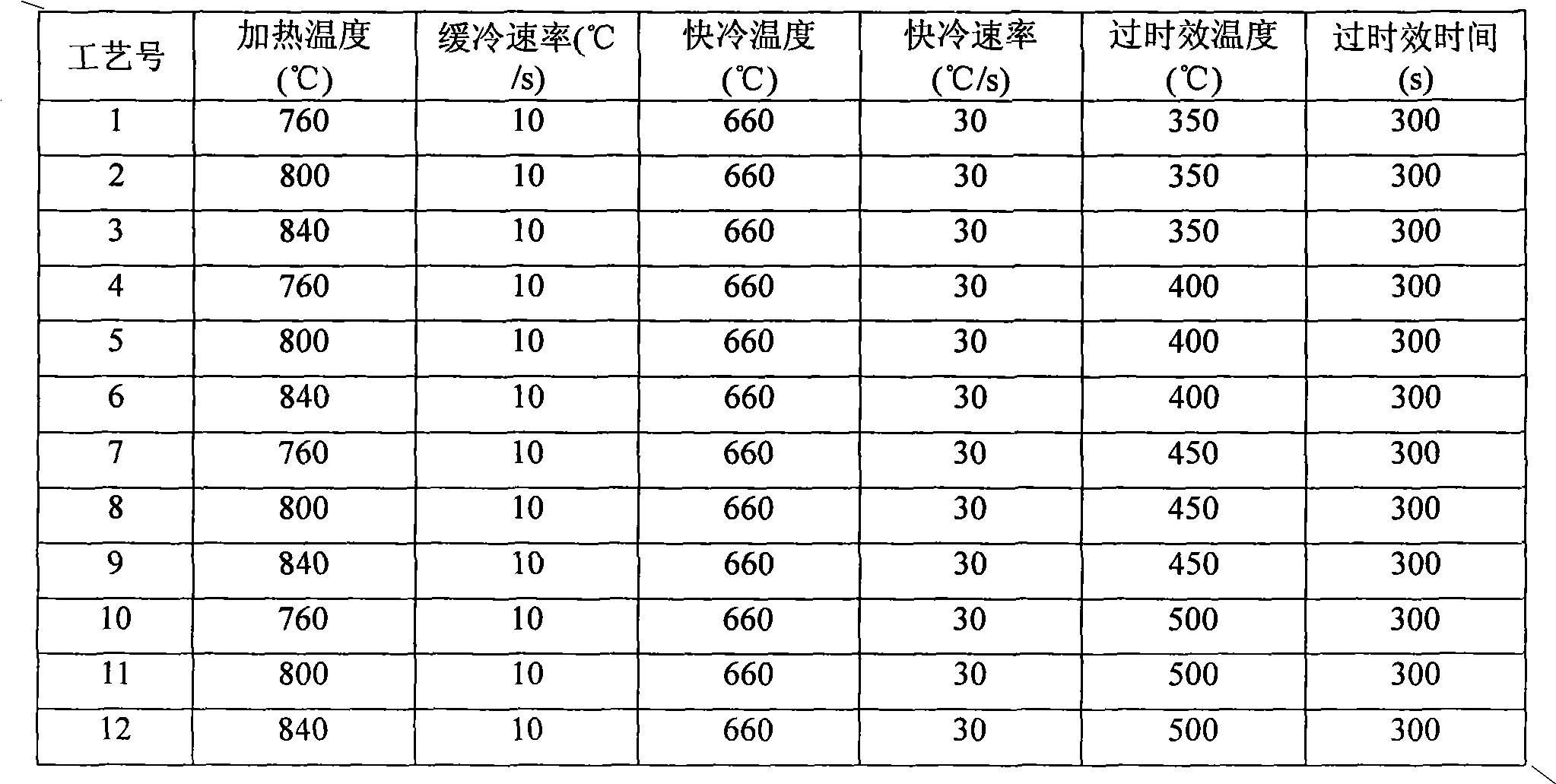

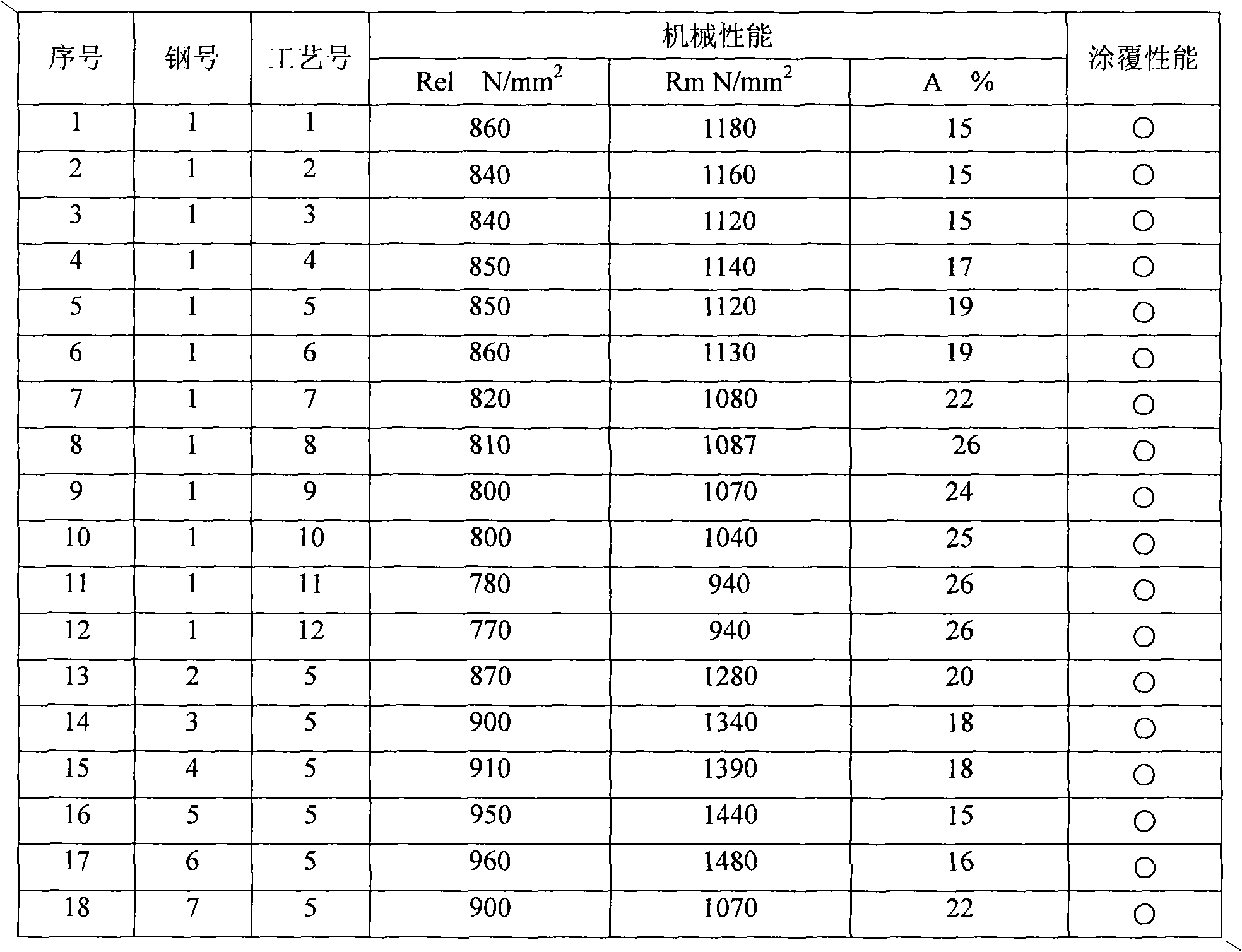

[0014] The preparation process of the high-strength cold-rolled phase-change plastic steel plate with good plasticity used in the embodiment of the present invention includes: converter smelting, LF furnace refining, continuous casting of slabs with a thickness of 135 mm or more, hot rolling at 1000-1250 ° C, and the final rolling temperature The temperature is 760-900°C, the coiling temperature is 560-700°C, and then cold-rolled at a cumulative reduction of 40%-80%, to make a steel plate with a thickness of 0.5-2.0mm. Then heat treatment: the cold-rolled steel plate is held at 710-850°C for 1-6 minutes, then rapidly cooled to 330-500°C at a rate of 10-50°C / s and held for 5-20 minutes, and finally heated at 5-20°C / s s rate air cooling to room temperature, you can get a high-strength cold-rolled phase-change plastic steel plate with good plasticity. The composition of the steel grades of the embodiments of the present invention is shown in Table 1, the annealing system is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com