Hydraulic fan-shaped support system for controlling steel frame deformation in tunnel construction

A tunnel construction and support system technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of inability to form a stable support system, poor contact between supports and steel frames, inconvenient processing and installation, etc. Potential safety hazards, shortening installation time, and ensuring the safety of tunnel construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

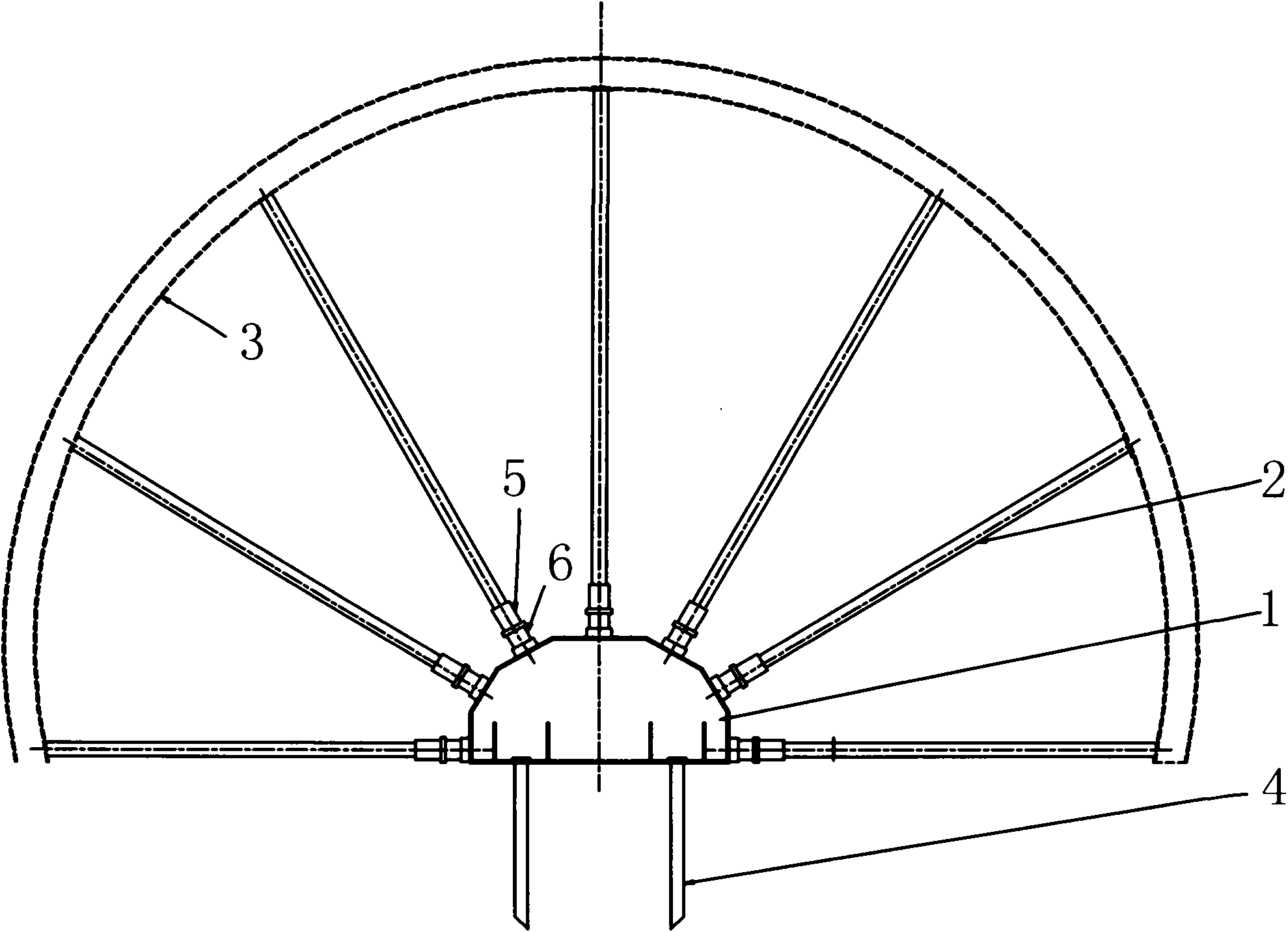

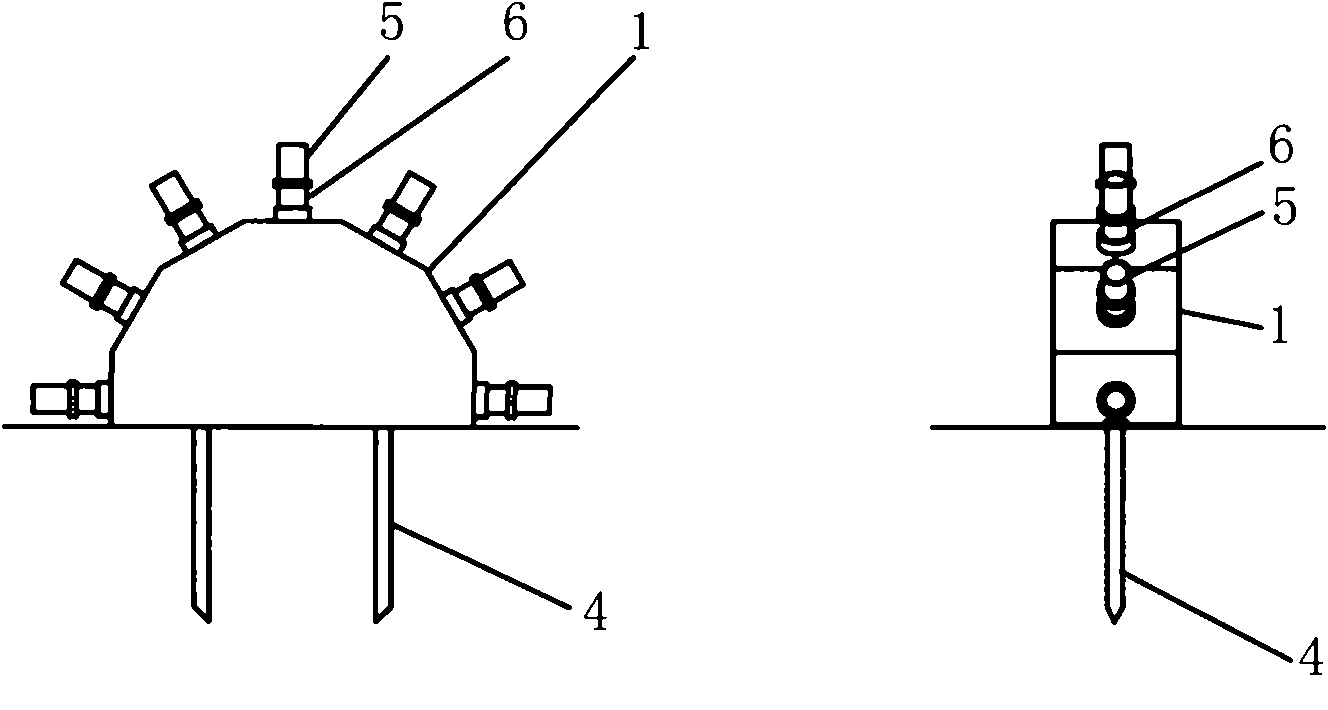

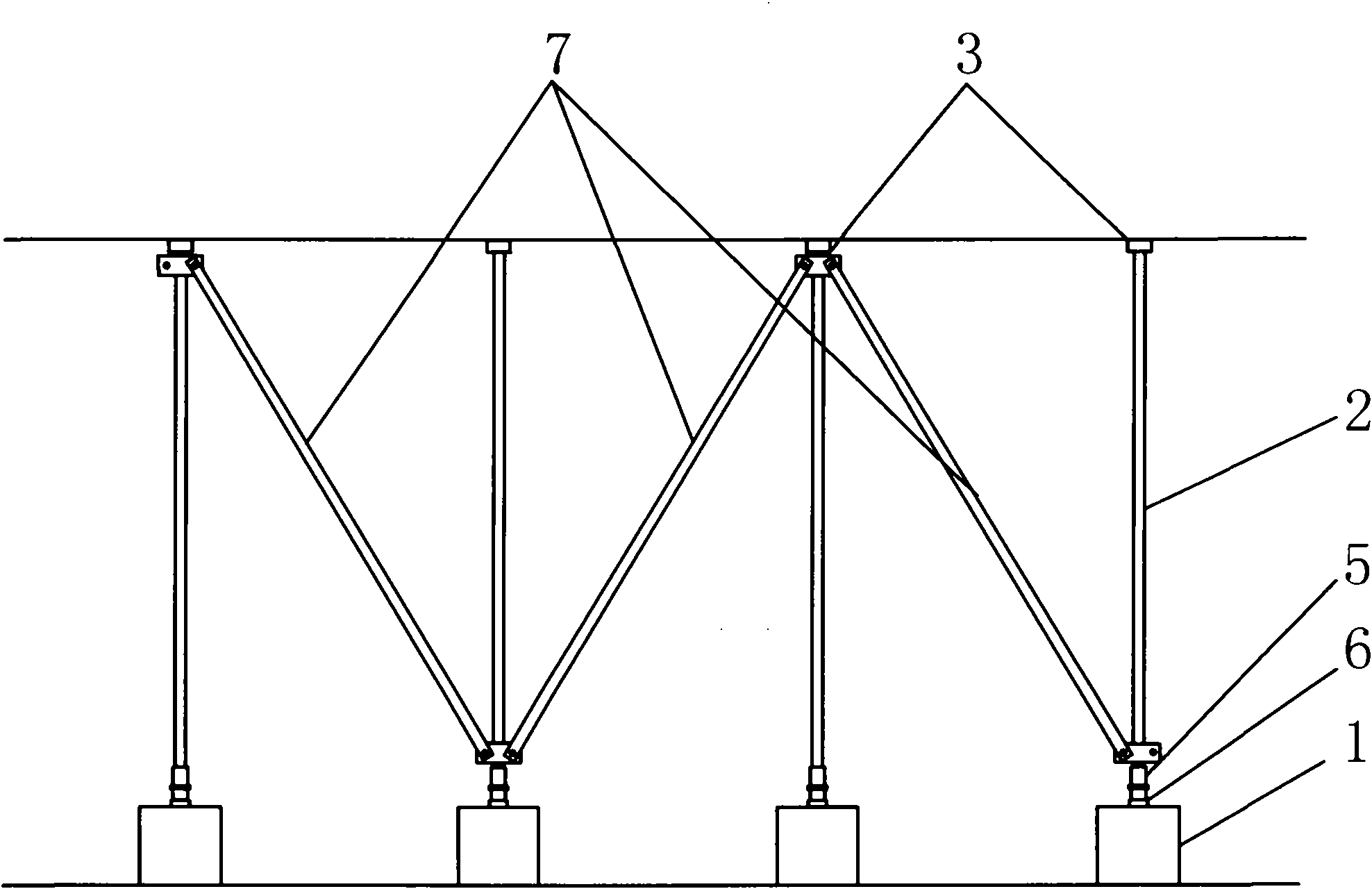

[0024] The present invention will be further explained below in conjunction with the drawings and embodiments: the present invention is suitable for when the deformation of the steel frame of the tunnel construction exceeds expectations, that is, the settlement exceeds the reserved settlement; the convergent deformation of the surrounding side wall invades the limit; or the monitoring amount through the tunnel It is found that the deformation does not converge; or when the amount of deformation changes sharply, the tunnel steel arch frame is temporarily reinforced.

[0025] The hydraulic fan-shaped support system used to control the large deformation of the steel frame in the tunnel construction. In the above case, the steel box base 1 is fixed in the middle of the ground in the tunnel, and the steel box base 1 is connected with flanges and bolts. A telescopic hydraulic cylinder 6 with a steel sleeve 5 on the top, the hydraulic cylinder 6 is connected to the hydraulic system, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com