Multi-fuel-loop used for premixing synthetic gas/ng dln in nozzle

A fuel and fuel source technology, applied to gas fuel burners, burners, combustion chambers, etc., can solve problems such as reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

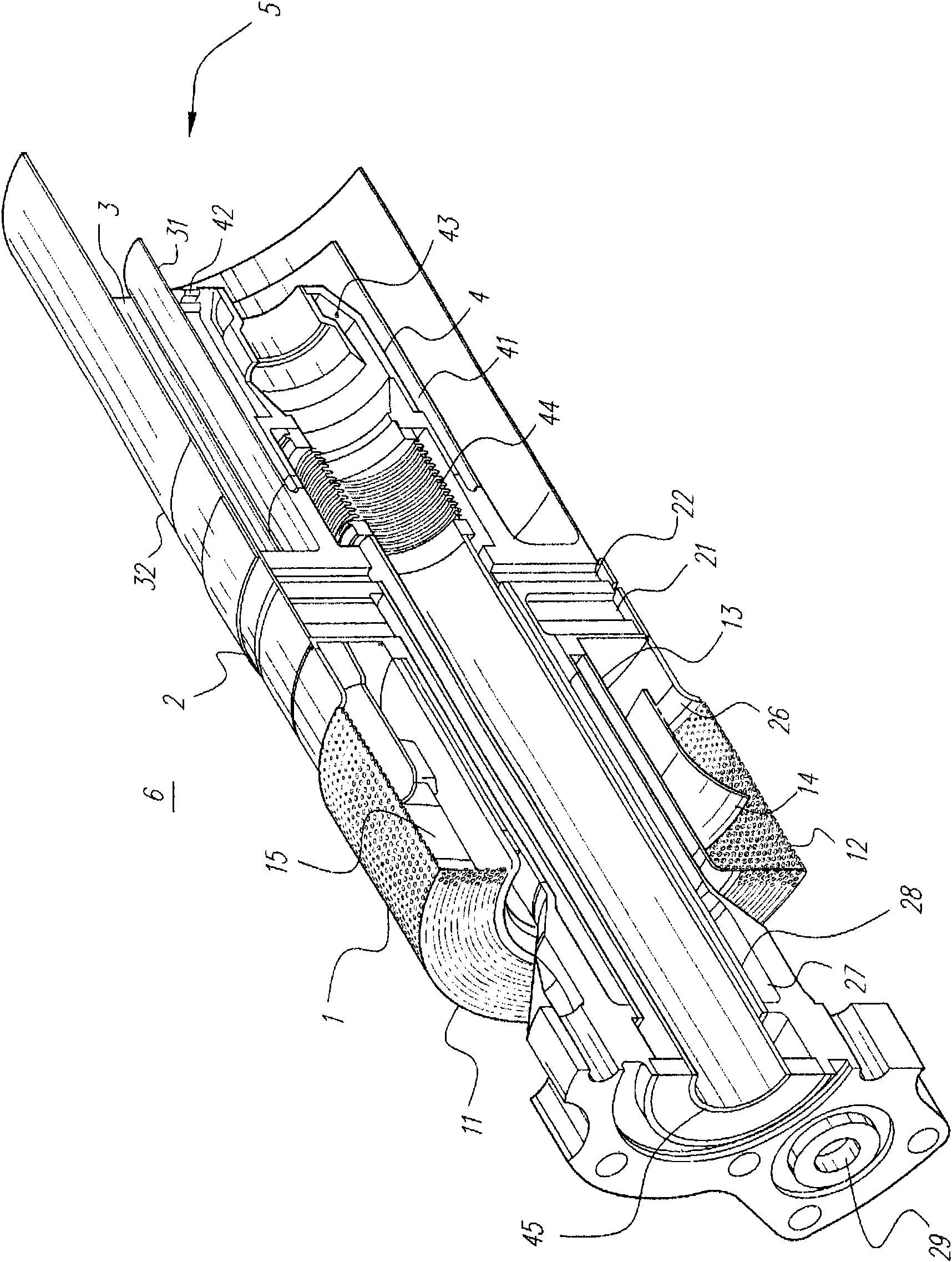

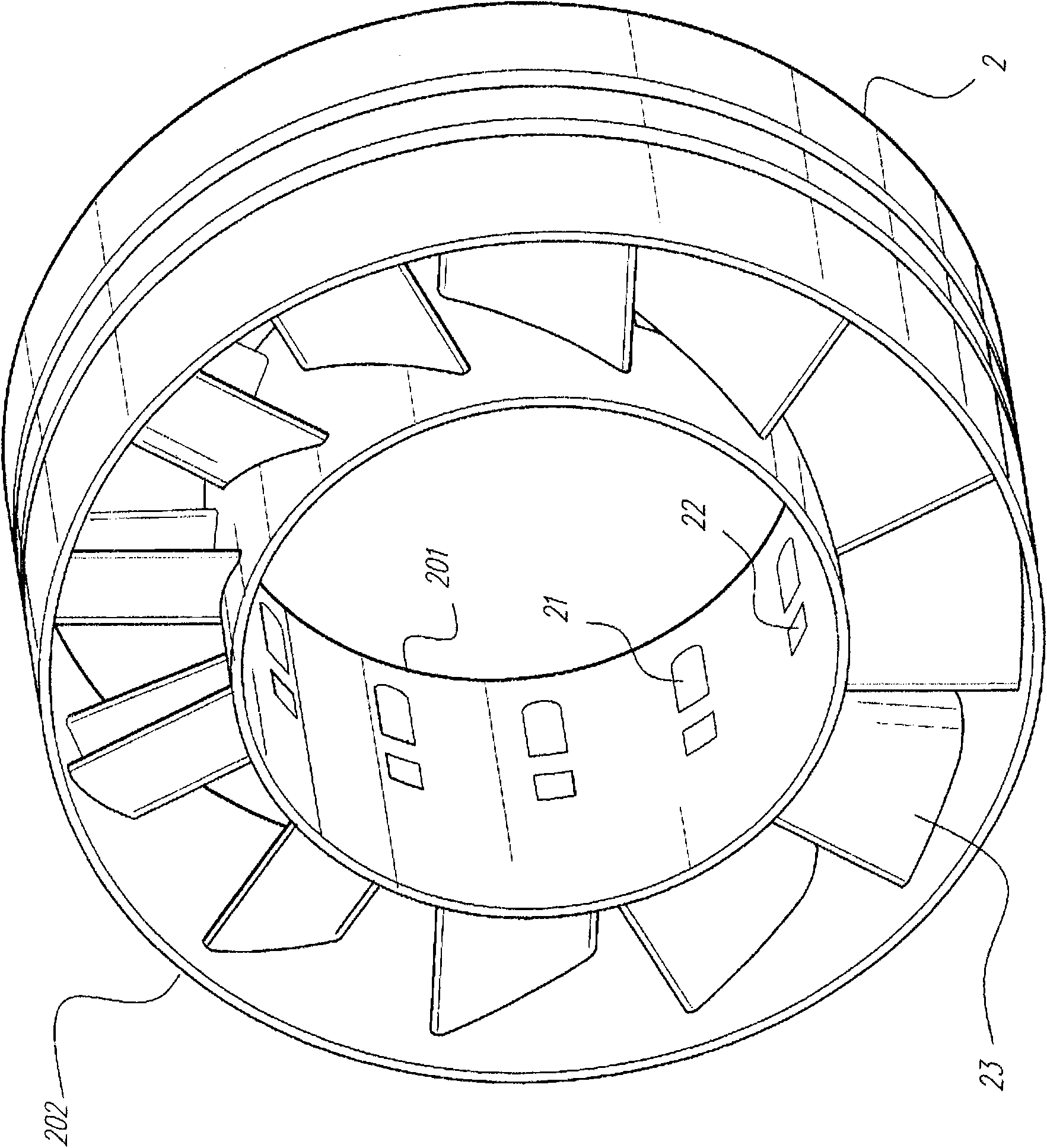

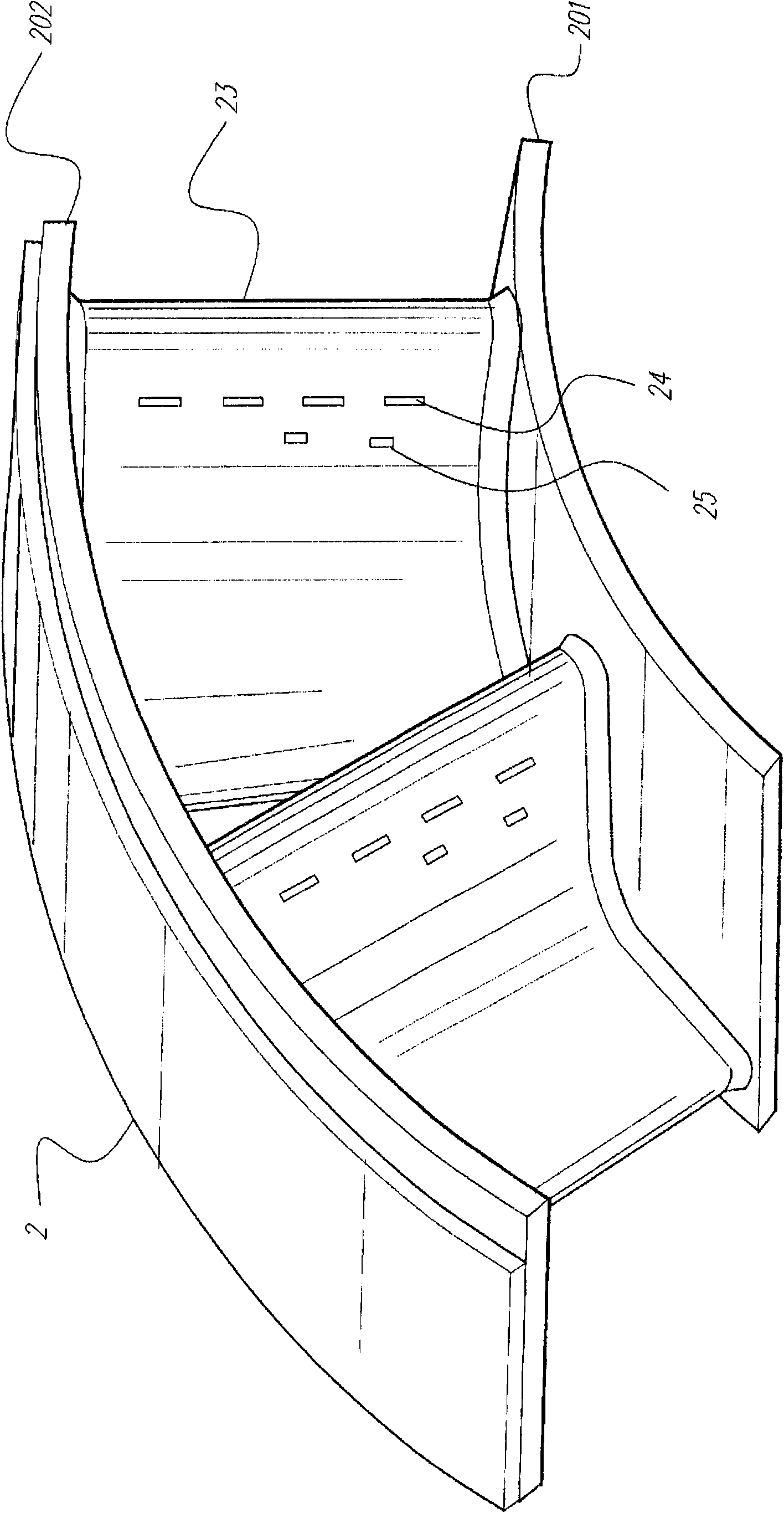

[0049] figure 1 is a section through the combustion apparatus described in U.S. Patent No. 6,438,961, while figure 2 with image 3 Shows details of the air swirler assembly that injects fuel through rotating vanes or swozzles. In practice, an air atomizing liquid fuel nozzle would be mounted in the center of the combustor assembly to provide dual fuel capability; however, this liquid fuel nozzle assembly does not form part of the present invention and has been omitted from illustration for clarity. The burner assembly is divided into four areas according to function, including the inlet flow regulator 1, the air swirler assembly for natural gas fuel injection (called the swirl nozzle assembly) 2, the annular fuel / air mixing passage 3, and the central diffusion flame Natural gas fuel nozzle assembly 4.

[0050] Air enters the burner from a high pressure chamber 6 which surrounds the entire assembly except for the discharge end which enters the reaction zone 5 of the burner....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com