Temperature control method for heating furnace based on heat accumulating type nozzle

A temperature control method and heating furnace technology, which are applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of inadaptability to the furnace temperature control of the original system and large investment of the all-digital discrete control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

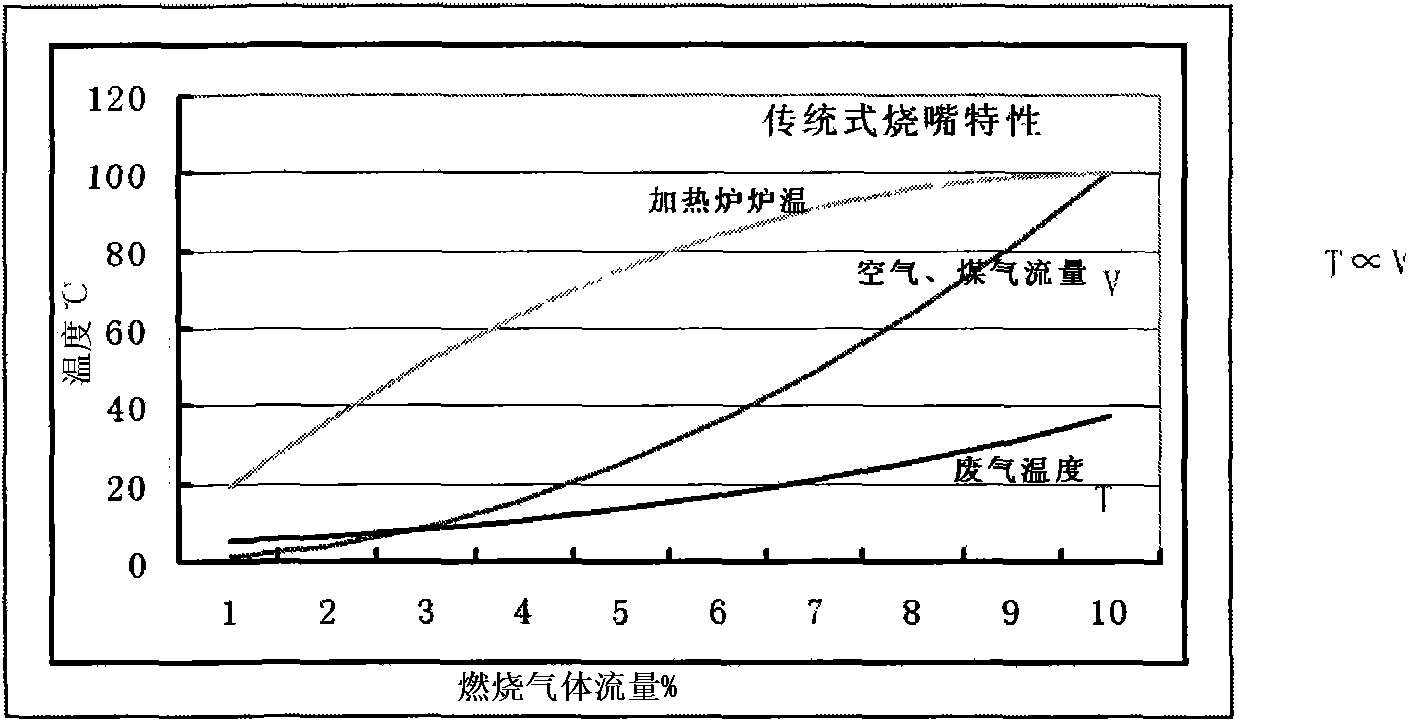

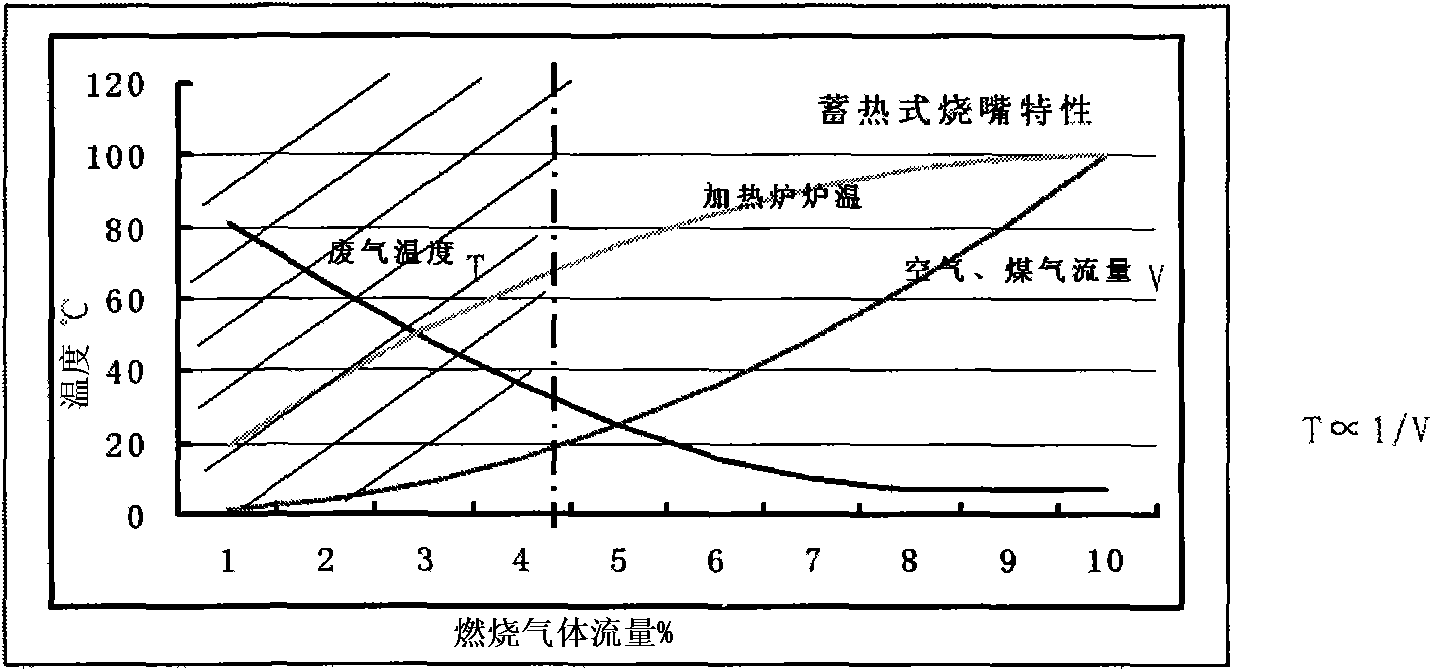

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The following takes the furnace with eight burners as an example to illustrate the digital discrete control. The burner numbers are A1, A2, A3, A4, B1, B2, B3, and B4, as shown in Table 1. There are five modes (the specific data are for reference only, and different furnaces need to obtain corresponding data through experiments), which can be used to control the burning and stopping to realize the rough adjustment of the temperature. It is generally considered to adopt a feed-forward method, and the overall temperature control strategy is controlled in the manner shown in Table 1.

[0021] Table 1 Digital Discrete Control

[0022] set temperature

[0023] When the set temperature changes from high to low, you can directly switch to the corresponding mode in mode B; when the set temperature changes from low to high, in order to reduce the heating time, you need to first put in MODE1, and cooperate with mode A to heat up at full speed , when the actual temperat...

Embodiment 2

[0025] Such as Figure 4 As shown, a more typical temperature control process. In the initial heating process, mode A is put into operation, Mode 1 is activated in mode B, and all burners burn. At this time, the gas flow rate is opened to the maximum (100%), and the temperature is raised with the maximum capacity. When reaching or approaching the set temperature, according to the PID control, the flow rate begins to decrease. When it decreases to about 40%, if the furnace temperature has not dropped to the set value, it is not appropriate to reduce the flow rate in order to prevent the exhaust gas from being too high. A mode in mode B closes part of the burners for rough temperature control. When the rough adjustment makes the temperature drop to a certain temperature (pre-control temperature, generally 30°C lower than the set temperature), the A mode is put into operation again, and the gas flow starts to be adjusted by PID until the set temperature, and then enters the stab...

Embodiment 3

[0027] When producing a certain product, the furnace temperature is set to 250°C. At this time, mode A is in a stable closed-loop control state, and the gas flow rate V is about 75%. The corresponding mode of mode B is MODE3, that is, A1, A2, B1, and B2 are in the OFF state. . When producing another product, the furnace temperature needs to rise to 300°C. At this time, according to the closed-loop control characteristics of mode A, the gas flow rate V quickly rises to 100%, and at the same time, the mode corresponding to mode B changes to MODE1, that is, A1, A2 and B1, B2 are switched to the ON state, so that all burners are fully opened. Cooperate with method A for rapid heating. When approaching or reaching 300°C, the gas flow rate V gradually decreases to 40%. Due to the inertia of the temperature, the actual temperature will still rise a little. After reaching the pre-control temperature of 270°C, mode A is put into operation again to raise the temperature, and the gas f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com