Method of making hollow concrete elements

A technology for concrete and components, used in the manufacture of tools, molds, supply devices, etc., to solve problems such as inefficiency, difficulty in detecting defects and inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention makes it possible to use prefabricated segmented elongated structures as an alternative to molded in situ structures or prefabricated integrally molded structures.

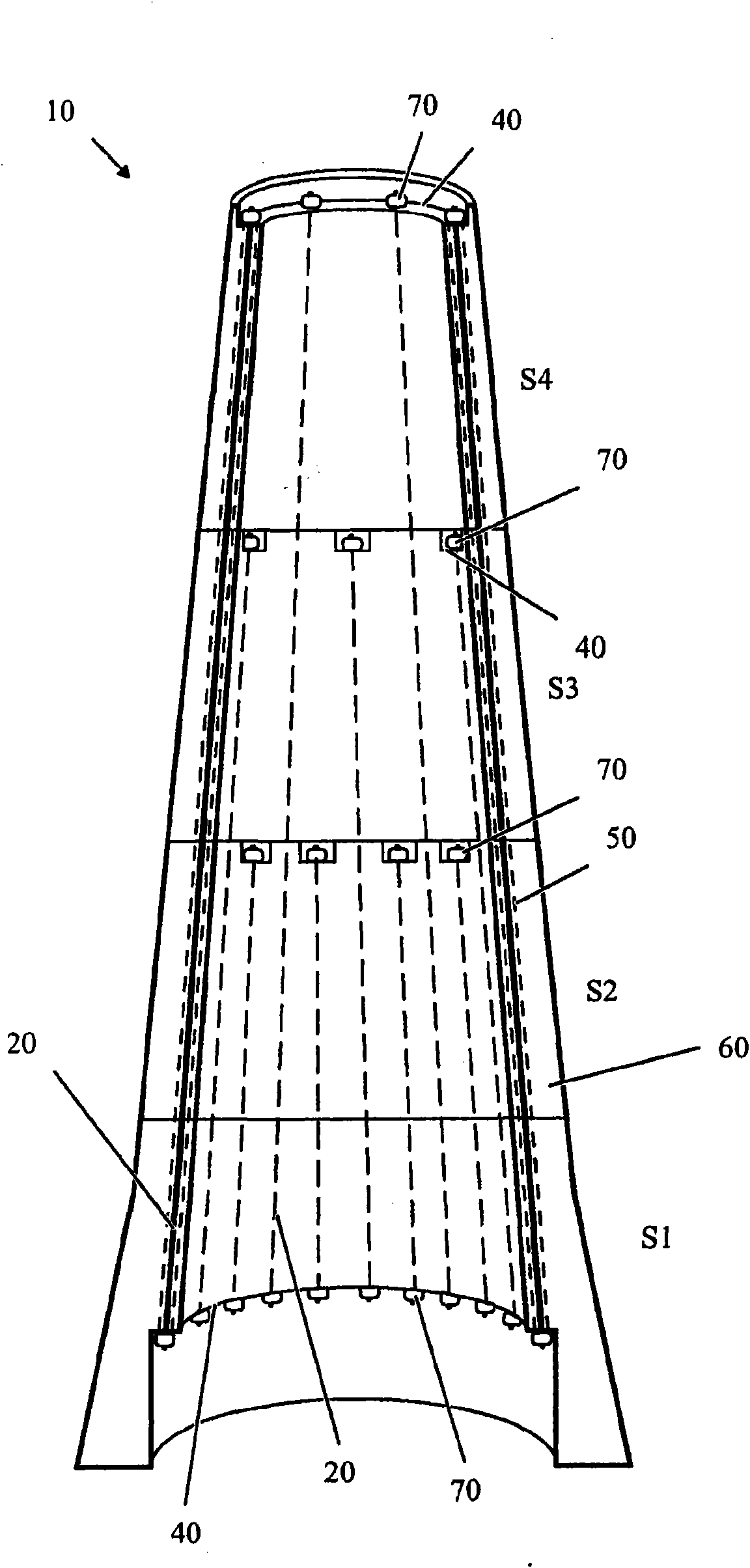

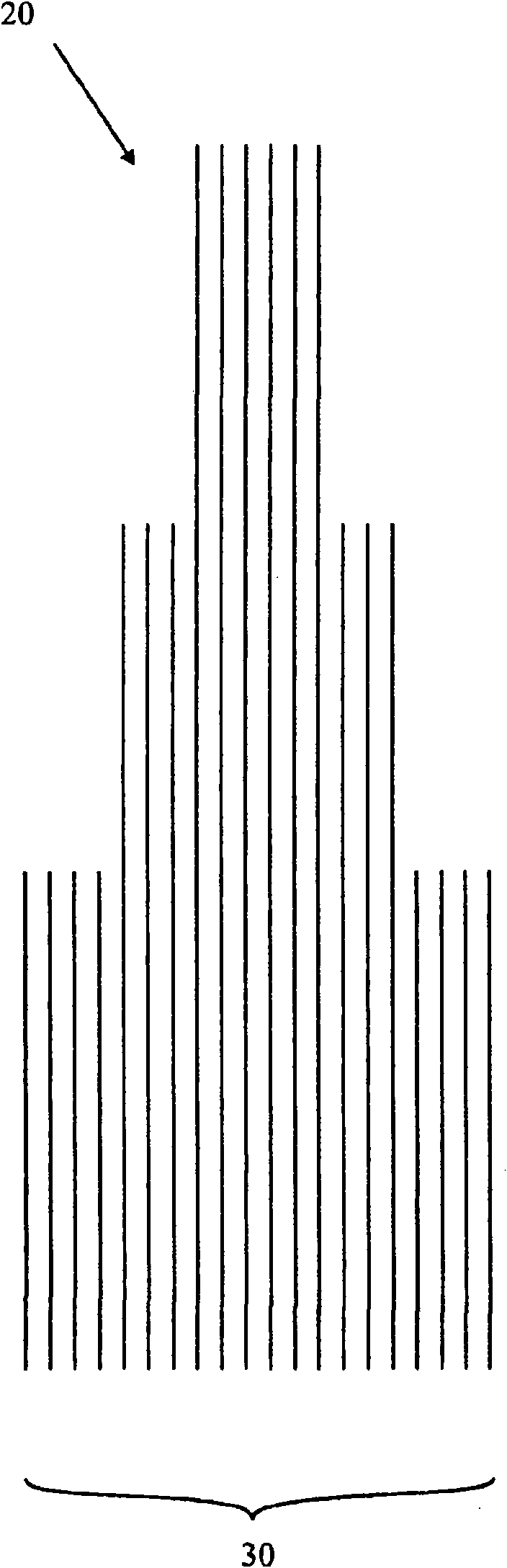

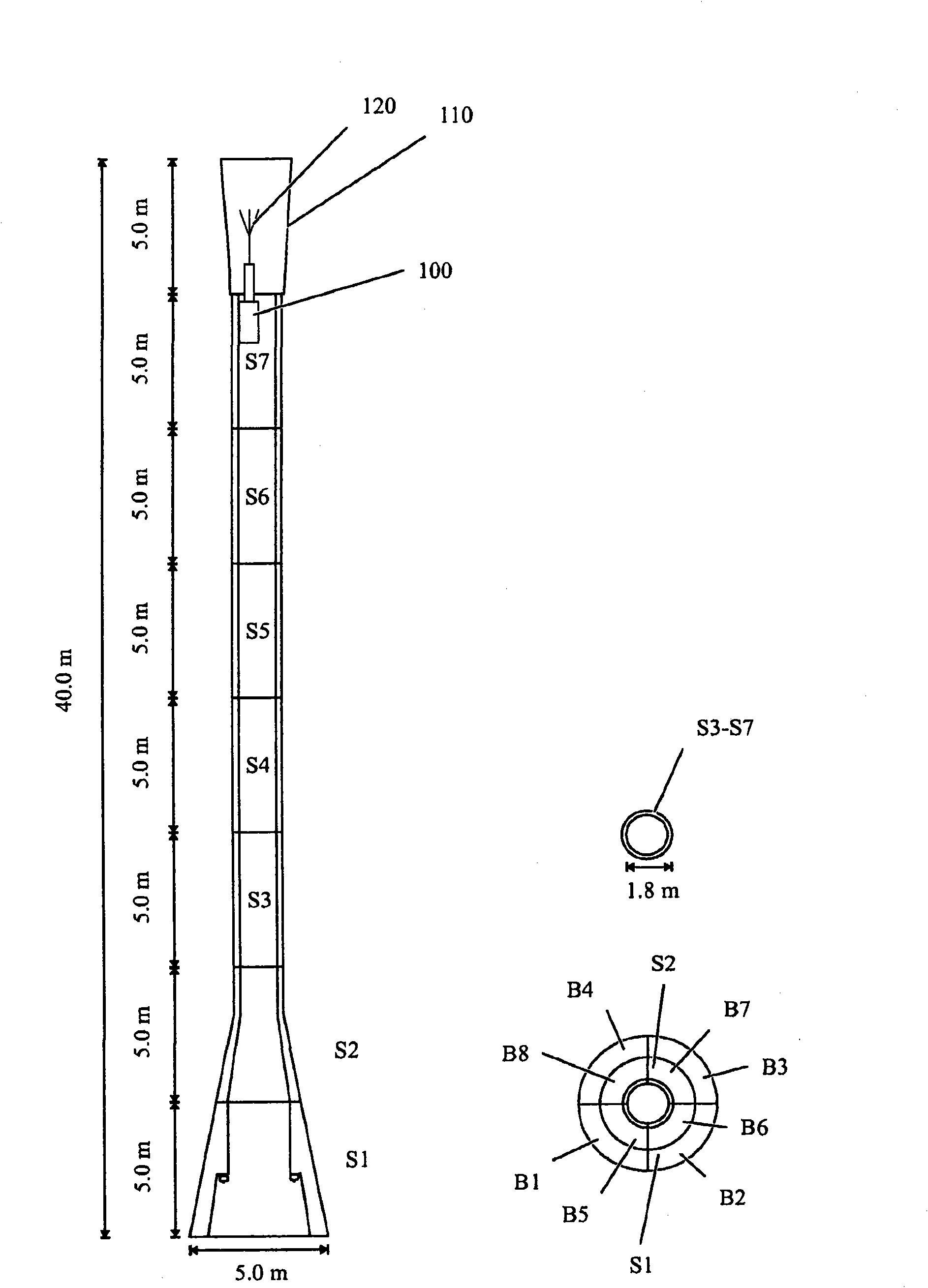

[0045] Figure 1a and 1b The elongated structure 10 along the longitudinal section S1-S4 is schematically shown. The elongated structure comprises: a base section S1; at least one intermediate section S2, S3; and a terminating section S4, wherein said sections are formed substantially of reinforced concrete. Segments S1-S4 are longitudinally interconnected by a plurality of elongate fastening members 20 which together form a longitudinally seamless longitudinal interconnection interconnecting base segment S1 to terminating segment S4. Even structure 30. In other words, it can be said that the plurality of elongate fastening members 20 together form a continuous longitudinal interconnection structure 30 throughout the segmented elongate structure 10 . As will be disclosed in more det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com