Coating process for cathode material lithium iron phosphate and lithium ion battery thereof

A lithium ferrous phosphate and lithium ion battery technology, which is applied to secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of poor adhesion between lithium ferrous phosphate materials and current collector aluminum foil, and achieve a simple process. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 18650

[0021] Embodiment Take the 18650 aluminum casing rate type lithium-ion battery as an example:

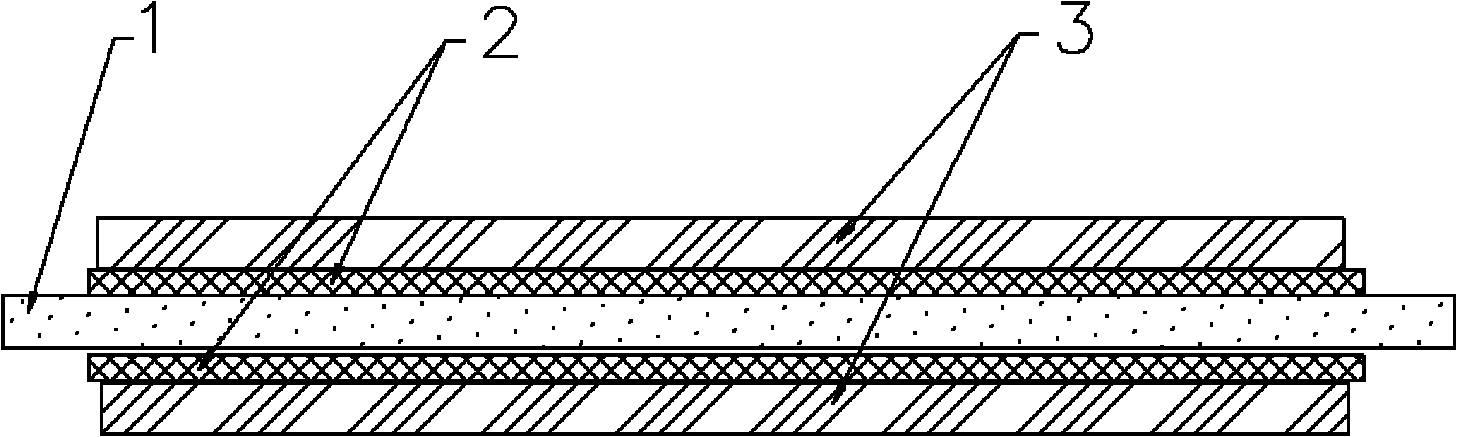

[0022] 1) Coating a layer of LiNi on the 18 micron aluminum foil 1 1 / 3 co 1 / 3 mn 1 / 3 AlO 2 It is the mixed slurry 2 of the active material, coated with a thickness of 22±2 microns, and dried. The ratio of the mixed slurry 2 is LiNi 1 / 3 co 1 / 3 mn 1 / 3 AlO 2 : PVDF (HSV900): C-B (V7): oxalic acid = 96: 2: 2: 0.008, the solvent is NMP (N-methylpyrrolidone);

[0023] 2) in LiNi 1 / 3 co 1 / 3 mn 1 / 3 AlO 2 A layer of mixed slurry 3 with lithium iron phosphate material as the active material is applied to the surface of the surface, and the coating thickness is 100±2 microns (single side), and dried. The proportion of mixed slurry 3 is LiFePO 4 : PVDF (HSV900): S-P: oxalic acid = 90: 7: 3: 0.01, the solvent is NMP (N-methylpyrrolidone), see Figure 1 .

[0024] 3) Use a roller press to compact the positive electrode to a thickness of 180 ± 2 microns (double-sided), cut the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com