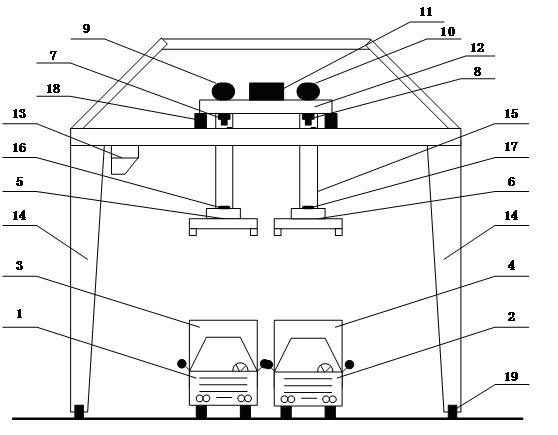

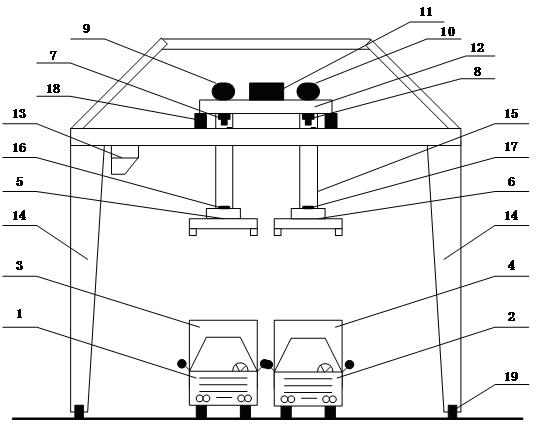

Positioning method of twin-lift spreader bridge crane based on image sensor

An image sensor and positioning method technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of complicated use, inconvenient maintenance, poor anti-interference ability, etc., and achieve practical, effective, low cost, and convenient use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific working process of the bridge crane image detection and positioning system involved in the present invention is as follows: (see attached figure 1 )

[0024] The new double-lift double-spreader bridge crane can simultaneously load and unload two 40-foot containers or four 20-foot containers. The bridge crane is equipped with two independent spreaders 5 and 6, which can work simultaneously or separately; the two video cameras 7 and 8 installed directly under the bridge crane trolley 12 can respectively take pictures of the two spreaders 5 and 6 The operating conditions of the spreader, and the captured video image information is transmitted to the video image processors 9 and 10 corresponding to the cameras 7 and 8 for analysis and processing; the working images of the spreader captured by the cameras can be analyzed and processed in real time, and the crane can be extracted. position information of the spreader, and calculate the swing angle and swing ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com