Dust absorbing device of mixing barrel in automatic wet powdery activated carbon adding equipment

A technology for powder activated carbon and dust absorption, which is applied in the fields of removing smoke and dust, adsorbing water/sewage treatment, chemical instruments and methods, etc. Low operating cost, solving dust pollution, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

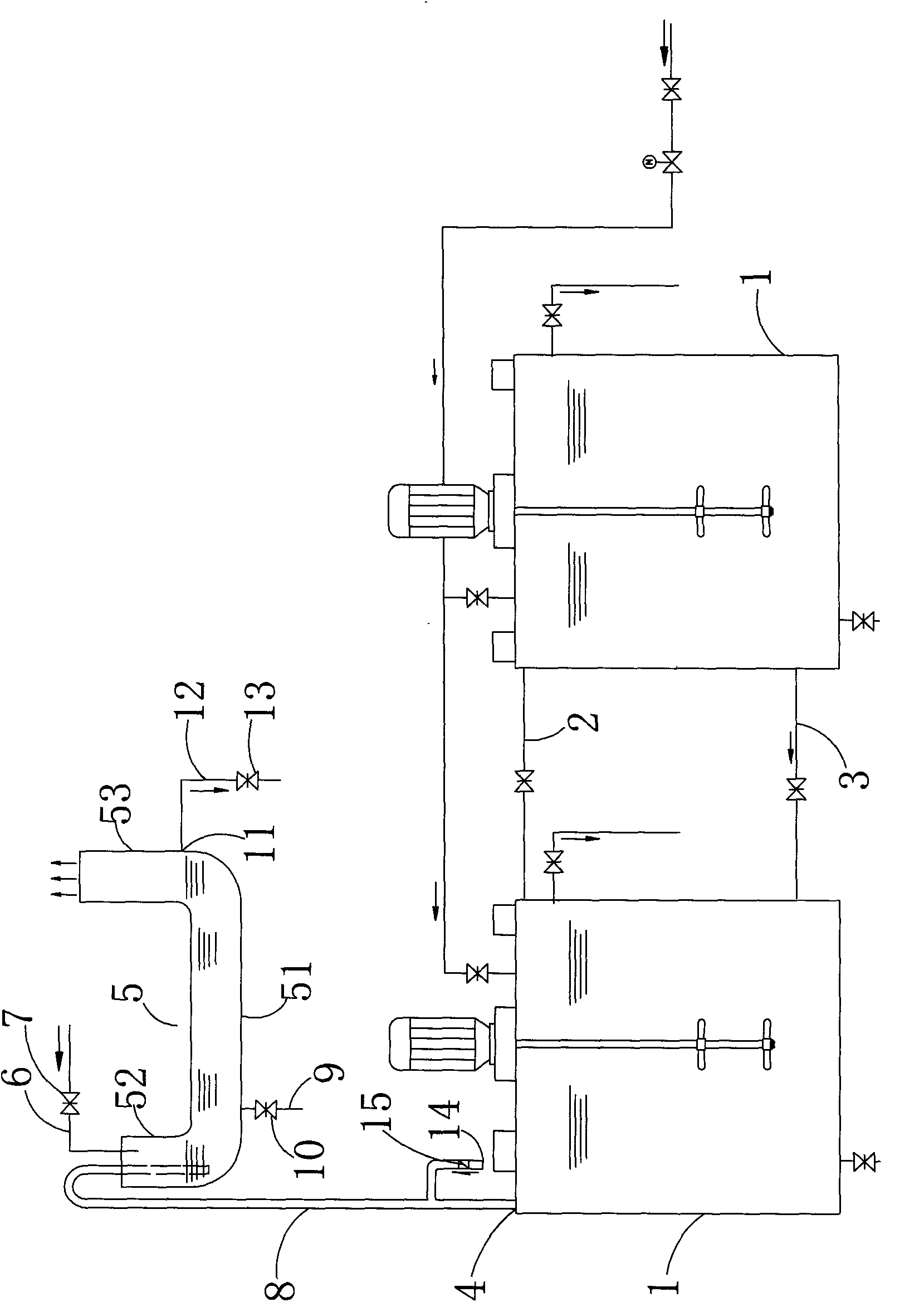

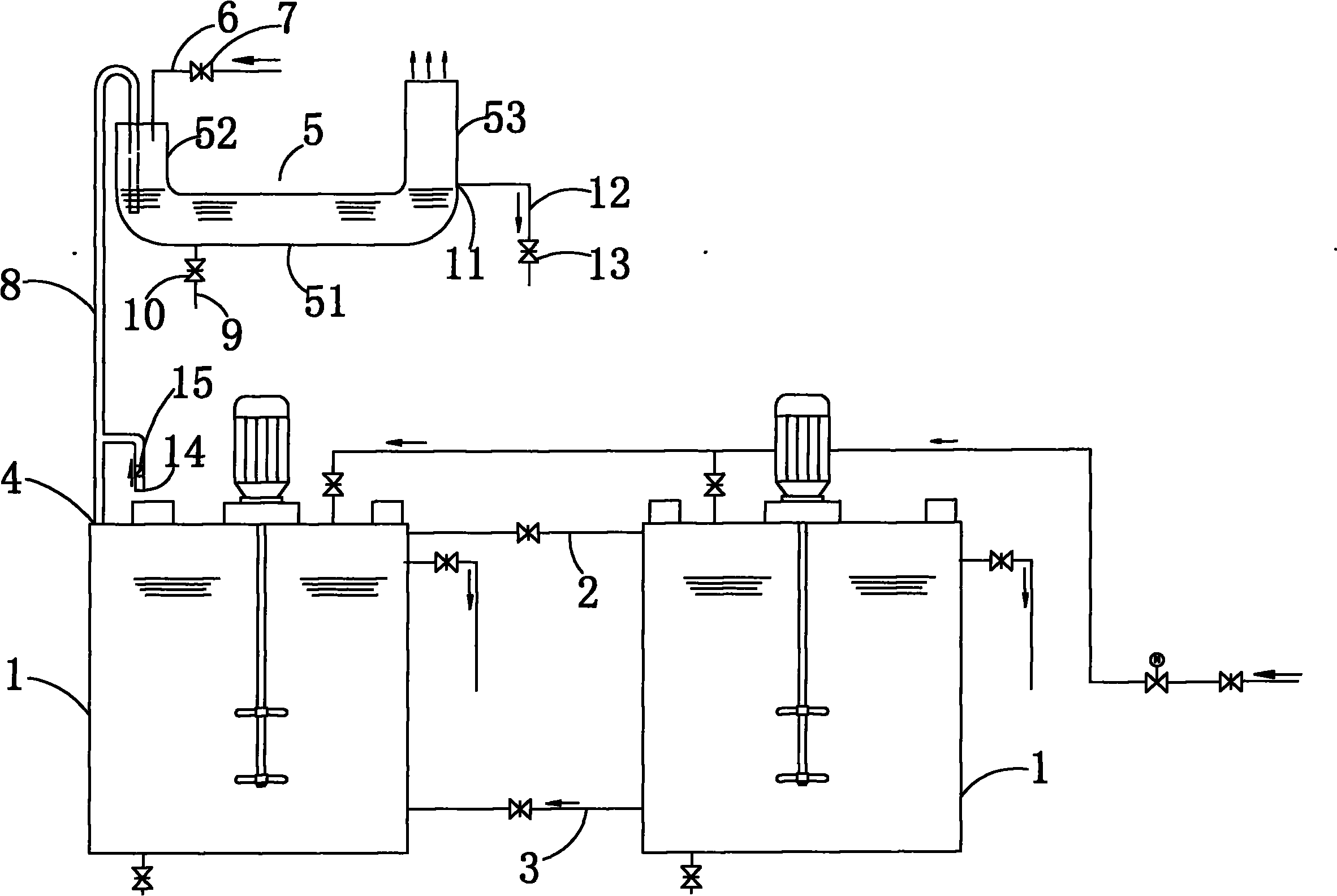

[0017] Embodiment: A dust absorbing device for a mixing cylinder in an automatic wet-type powder dosing device for powdered activated carbon. The lower parts of the mixing cylinders are connected through connecting pipes 3, at least one of the upper ends of the mixing cylinders is provided with a breathing port 4, the inside of the absorption tank 5 communicates with the outside atmosphere, and the upper part of the absorption tank is connected with a water supply pipe 6, and the water supply pipe is provided with a water supply pipe. Valve 7, the water supply valve can block the water circulation in the pipeline where it is located, one end of the breathing tube 8 is connected to the breathing port, the other end of the breathing tube extends into the liquid in the absorption tank, and the bottom of the absorption tank is connected There is a vent pipe 9, and a vent valve 10 is arranged on the vent pipe, and the vent valve can block the liquid circulation in the pipeline where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com