Fully-automatic laser surface treatment machine for metal clad plate

A technology of metal composite board and surface treatment machine, which is applied in the field of laser treatment, can solve the problems of increasing labor intensity of workers, industrial dust pollution, inhumanization, etc., and achieve the effect of protecting health and solving dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

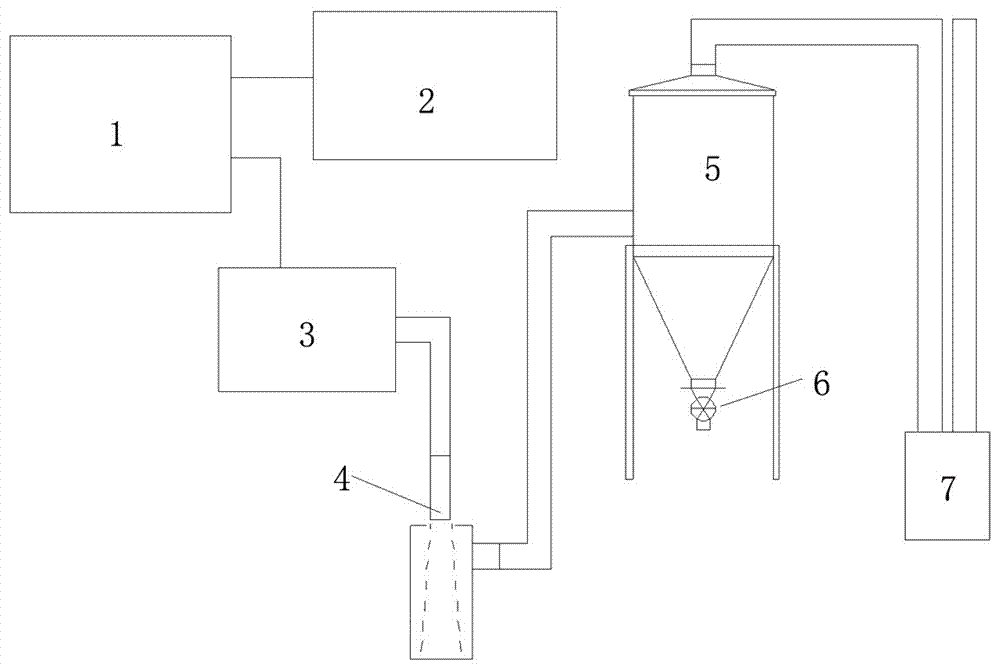

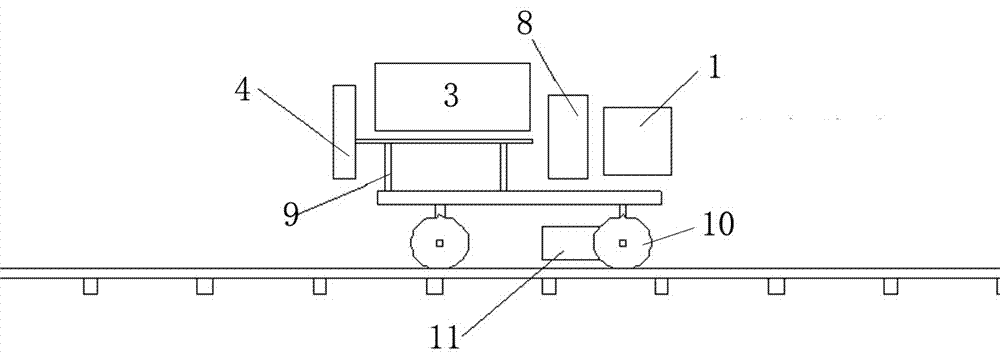

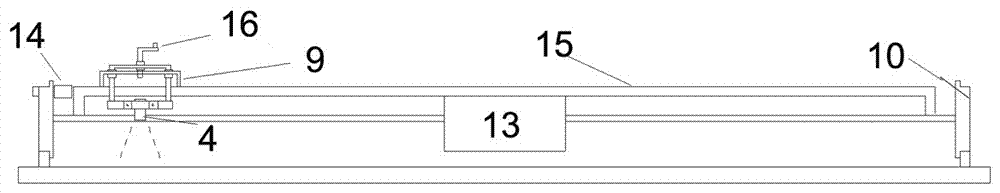

[0022] A fully automatic laser surface treatment machine for metal composite panels, including a PIC control system 1, an operating system 2 connected to the PIC control system 1, a laser processing system, and a dust removal system 8; the laser processing system and the dust removal system 8 are both located on the operating system 2 , the laser processing system is connected to the dust removal system 8 through a hose. Described running system 2 comprises running support 15, driving wheel 10 and first speed-regulating motor 11, and described first speed-regulating motor 11 is connected with first speed reducer 13, and described running support 15 is provided with driving wheel 10, The driving wheel 10 is connected with a first speed regulating motor 11 . The laser processing system includes a laser generator 3 , a pulsed laser head 4 and a translation device 9 . The translation device 9 is located on a running support 15 . The first speed-regulating motor 11 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com