A production line for processing magnetic abrasives and its use method

A magnetic abrasive and production line technology, applied in grain processing and other directions, can solve the problems of dust pollution, physical health injury of workers, consumption of workers' time and energy, etc., and achieve the effect of high degree of automation, shortening production cycle and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

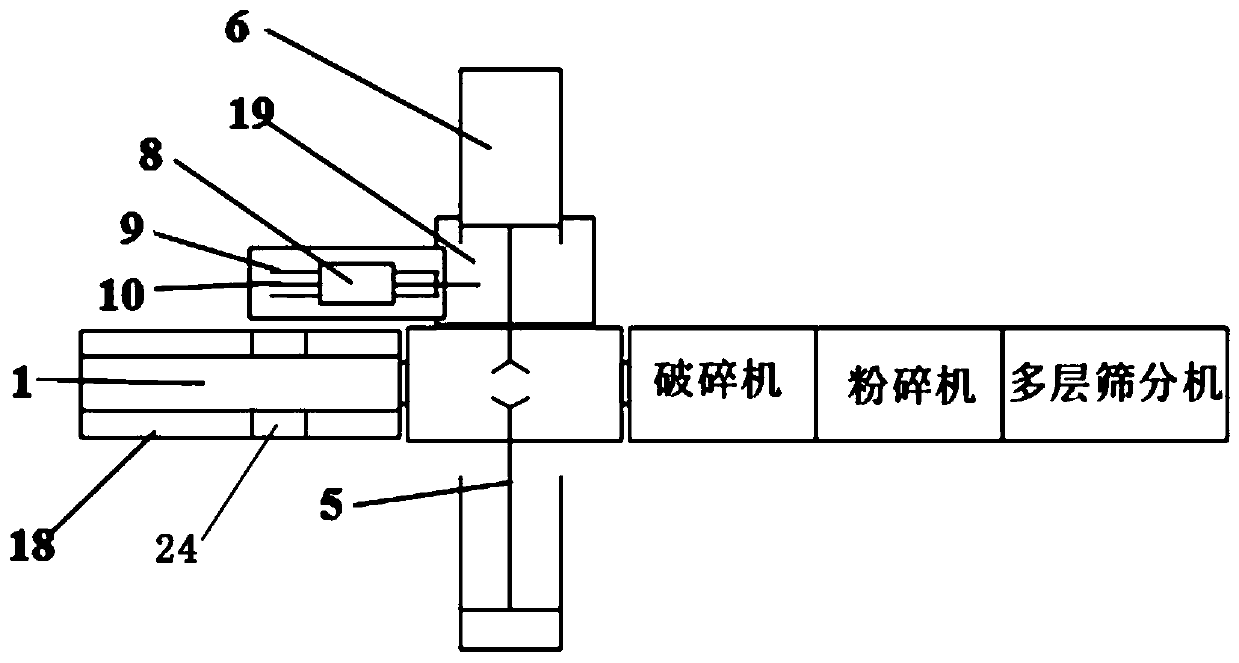

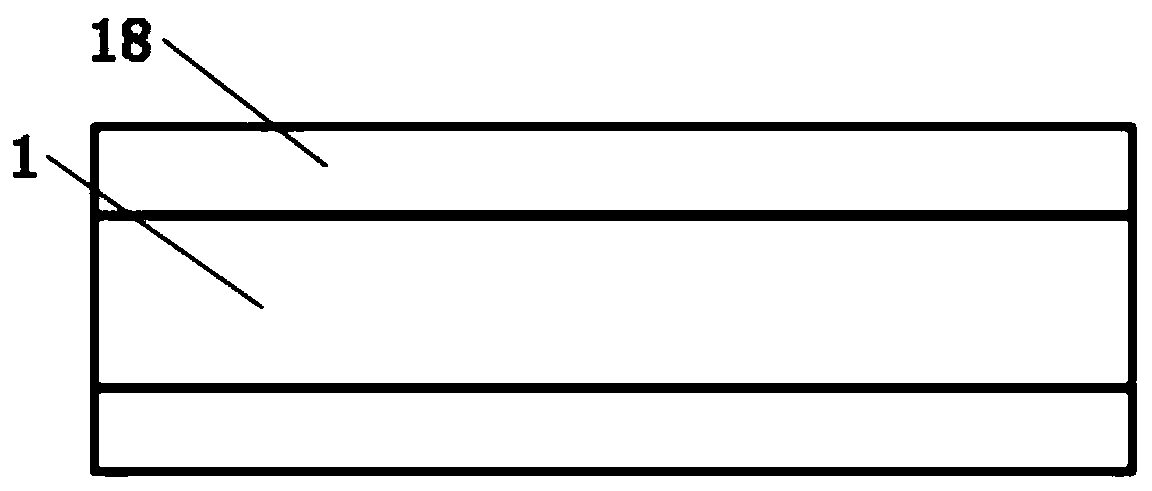

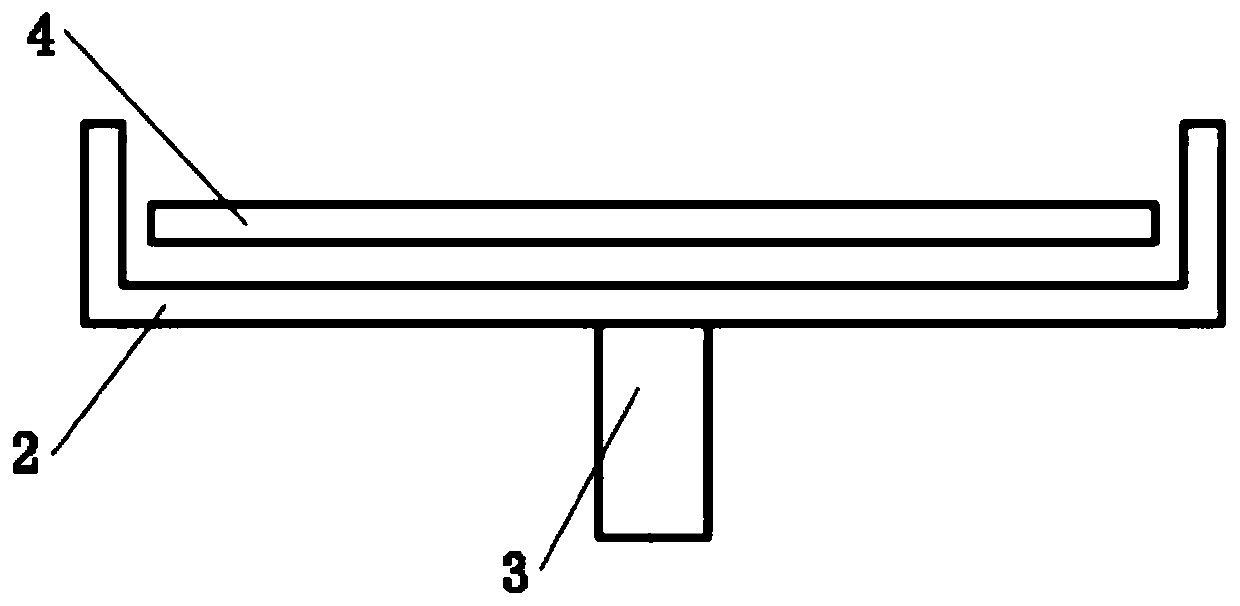

[0029] See Figure 1-Figure 7 , a production line for processing magnetic abrasive materials, including a conveyor 1, a buffer zone, a crusher 11, a pulverizer 12, a multi-layer screening machine 13, a rectifying plate 18, a waste recycling device 19, a manipulator 5, an electric cylinder 6, a mechanical gripper 7, Drill floor 8, slide rail 9, ball screw 10, deceleration device 24; the buffer zone is located at the end of the conveyor 1, and the end of the buffer zone is provided with a crusher 11, a pulverizer 12, and a multi-layer screening machine 13 in sequence. There are two manipulators 5 driven by electric cylinders 6, mechanical grippers 7 are connected to the ends of the manipulators 5, a waste recovery device 19 is provided at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com