UV curable plastic paint

A plastic paint and light-curing technology, applied in the direction of coating, etc., can solve the problems of shrinkage cavity, streaks, poor construction leveling, etc., and achieve the effect of high fullness, easy construction and good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

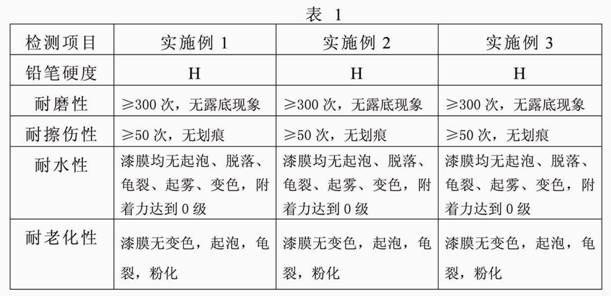

Examples

Embodiment 1

[0010] Dissolve the initiator HCPK 2.5% with 10% ethyl acetate solvent completely, then add HMPP 2.5%, stir evenly, and filter. Then 50% of modified epoxy UV resin, 15% of polyurethane UV resin, 10% of TPGDA active monomer, 10% of TMPTA active monomer and initiator mixture are mixed in order to avoid light, and after stirring, filter to obtain the present invention. UV light curing plastic paint.

Embodiment 2

[0012] Dissolve the initiator HCPK 2.5% with 5% ethyl acetate solvent completely, then add HMPP 2.5%, stir evenly, and filter. Then modified epoxy UV resin 55%, polyurethane UV resin 15%, TPGDA active monomer 10%, TMPTA active monomer 10% and initiator mixture are mixed in order to avoid light, after stirring, filter to obtain the present invention UV light curing plastic paint.

Embodiment 3

[0014] Dissolve the initiator HCPK 2.5% with 5% ethyl acetate solvent completely, then add HMPP 2.5%, stir evenly, and filter. Then 55% of modified epoxy UV resin, 10% of polyurethane UV resin, 15% of TPGDA active monomer, 10% of TMPTA active monomer and initiator mixture are mixed in order to avoid light, after stirring, filter to obtain the present invention UV light curing plastic paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com