Beta titanium alloy material and preparation method thereof

A technology of beta titanium alloy and titanium alloy, applied in the field of beta titanium alloy material and its preparation, can solve the problems of inability to remove macrosegregation, increase the dispersion of mechanical property data, etc., and achieve excellent cold and hot processing performance, high strength and low cost Effect

Active Publication Date: 2011-01-05

LUOYANG SUNRUI TI PRECISION CASTING

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this material Fe has a great tendency to segregate. Macroscopic segregation changes the macrostructure greatly, thus greatly increasing the dispersion of mechanical property data. Macroscopic segregation cannot be removed by heat treatment or plastic processing.

Moreover, in the preparation process of β-titanium alloy materials such as Ti-4.3Fe-7.1Cr at home and abroad, there are few reports on forging processes such as three-upsetting and three-drawing to refine grains.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

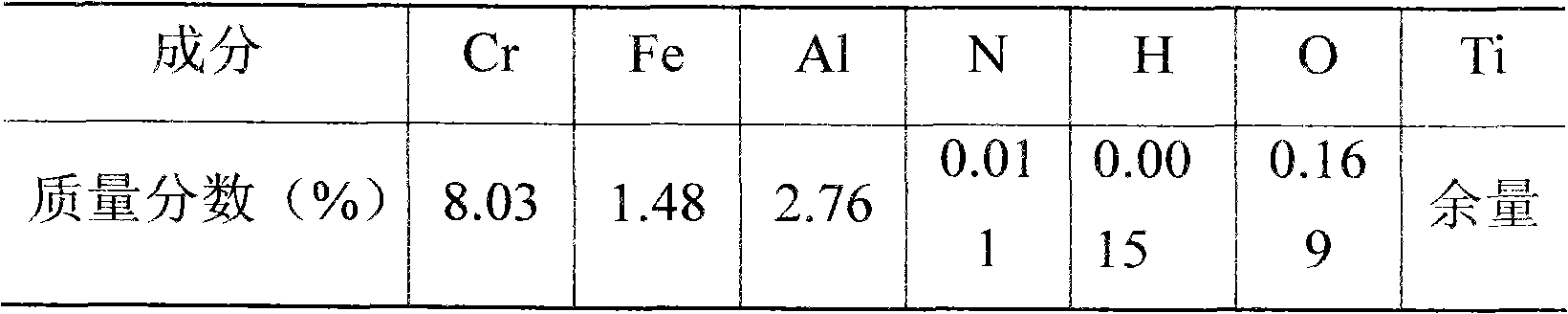

The invention provides a beta titanium alloy material, consisting of the following components in percentage by mass: 83.0 to 88.0 percent of Ti, 8.0 to 13.0 percent of Cr, 0.5 to 1.5 percent of Fe, 2.0 to 4.0 percent of Al, and other trace impurities. The preparation method comprises the following steps: preparing the raw materials according to the mass percentage required by the beta titanium alloy material; smelting the mixture in a vacuum induction furnace with the vacuum degree of between 0 and 5Pa and the smelting power of 200KW after uniform mixing; cutting and removing the sink hole part of an ingot after smelting; and forging the ingot at the temperature which is higher than beta-phase change temperature and lower than 1,000 DEG C. The titanium alloy has the advantages of lower cost, higher strength, higher elongation rate and higher impact toughness; after solid solution treatment, the whole the alloy is a metastable beta-phase tissue, the alloy has excellent cold and heat processing performance, and the cold working rate achieves 87.2 percent.

Description

A kind of beta titanium alloy material and preparation method thereof technical field The invention relates to a titanium alloy material technology, in particular to a β titanium alloy material and a preparation method thereof. Background technique In the titanium alloy system, β titanium alloy has the highest specific strength and good cold workability. β-titanium alloys were first used for aviation and military applications, but at present, industrial β-titanium alloys are more and more widely used in civilian fields, such as chemical industry, medical treatment, and sports equipment. In the existing β-titanium alloys, it is necessary to add a large amount of expensive β-stabilizing elements such as V, Mo, Nb, Ta, etc., for example, Ti-10V-2Fe-3Al, Ti-15V-3Al-3Cr-3Sn, Ti-3Al -8V-6Cr-4Mo-4Sn, Ti-13V-11Cr-3Al, Ti-15Mo-5Zr-3Al, Ti-29Nb-13Ta-4.6Zr, etc. For example: Ti1023 (Ti-10V-2Fe-3Al) alloy was successfully developed by Timet Company of the United States in 1971. It ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C14/00C22C1/02C22F1/18B21J5/00

Inventor 陈志强罗皓周洪强姜建伟

Owner LUOYANG SUNRUI TI PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com