Rock-fill concrete (RFC) and cemented sand and gravel (CSG) composite material dam as well as design and construction method thereof

A technology of rockfill concrete and cemented sand and gravel, which is applied in the field of gravity dam, can solve the problems of poor impermeability, large contact surface between the dam body and bedrock, and increased engineering quantity, so as to reduce the engineering cost, shorten the construction period, The effect of simplifying construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

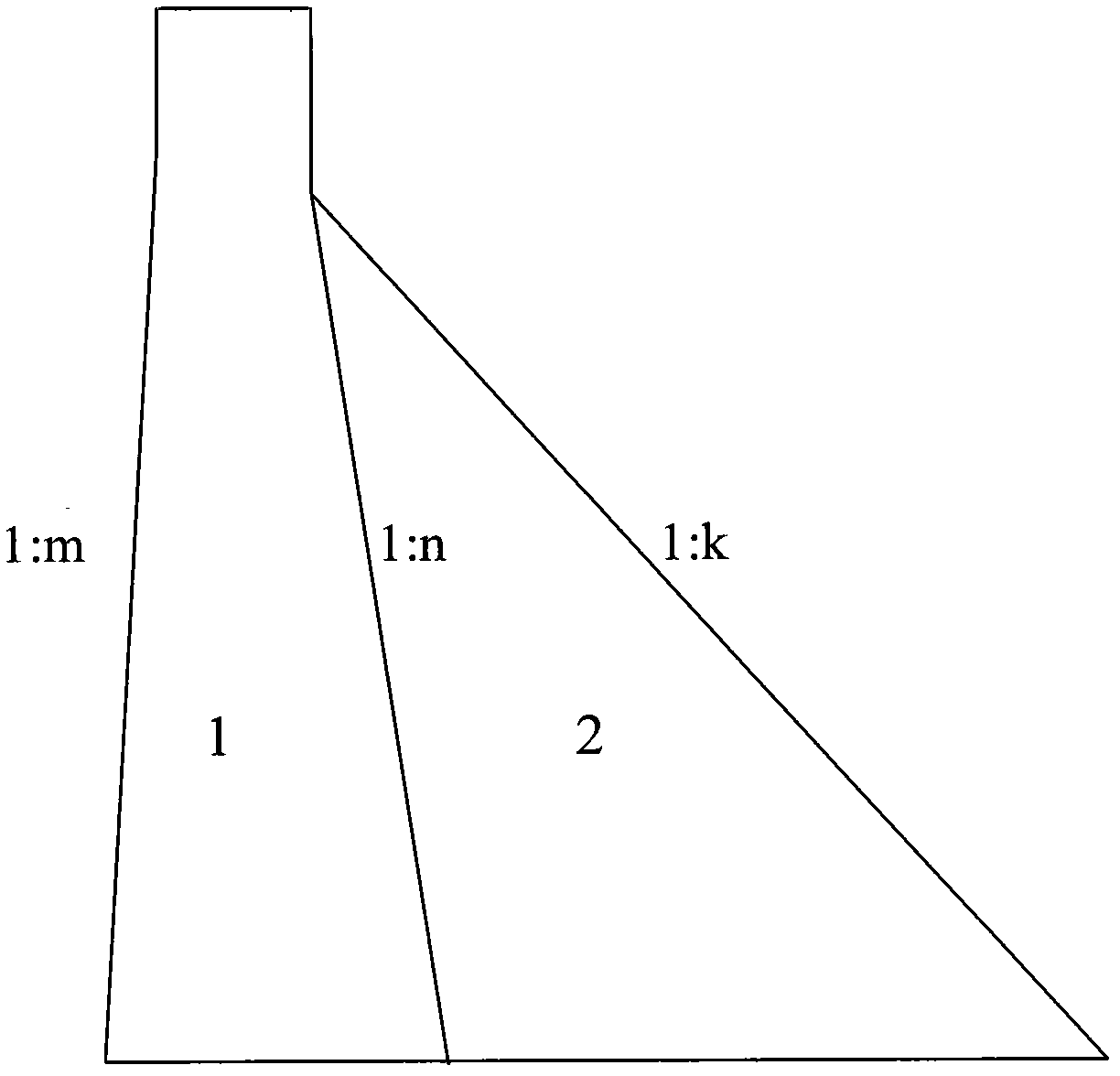

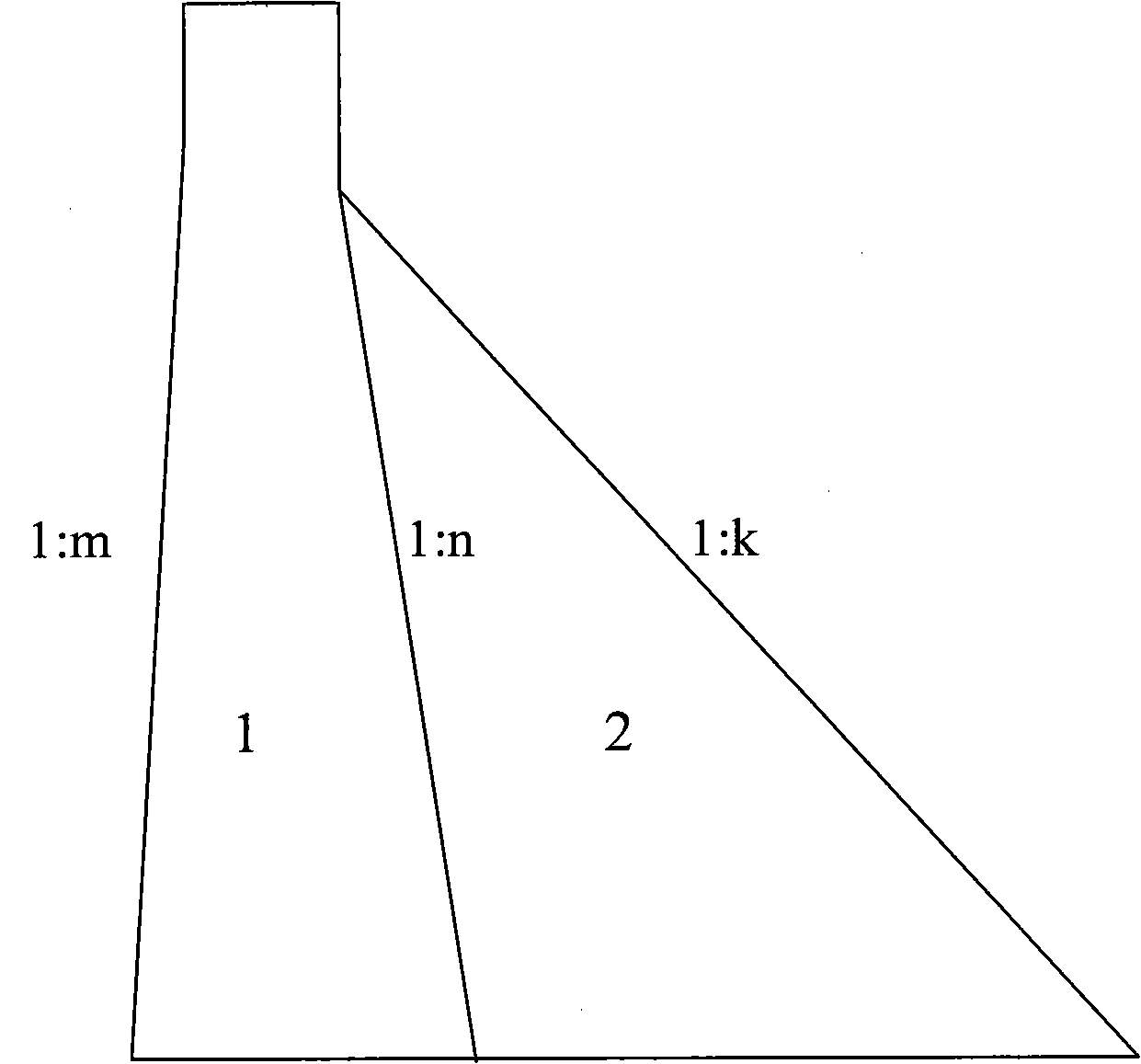

[0021] exist figure 1 Among them, the composite material dam body is composed of a rockfill concrete part 1 and a cemented sand and gravel part 2, the upstream side of the composite material dam is the rockfill concrete part 1, and the downstream side is the cemented sand and gravel Part 2. The upstream side of the dam body is poured with rock-fill concrete material, which can be constructed according to the construction method of rock-fill concrete dam; while the downstream side is poured with cemented sand and gravel material, which can be constructed according to the construction method of cemented sand-gravel dam.

[0022] According to the relevant requirements of the design specification for concrete gravity dams, the rigid body limit equilibrium method and the material mechanics method are used to calculate the anti-sliding stability and stress level of the dam body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com